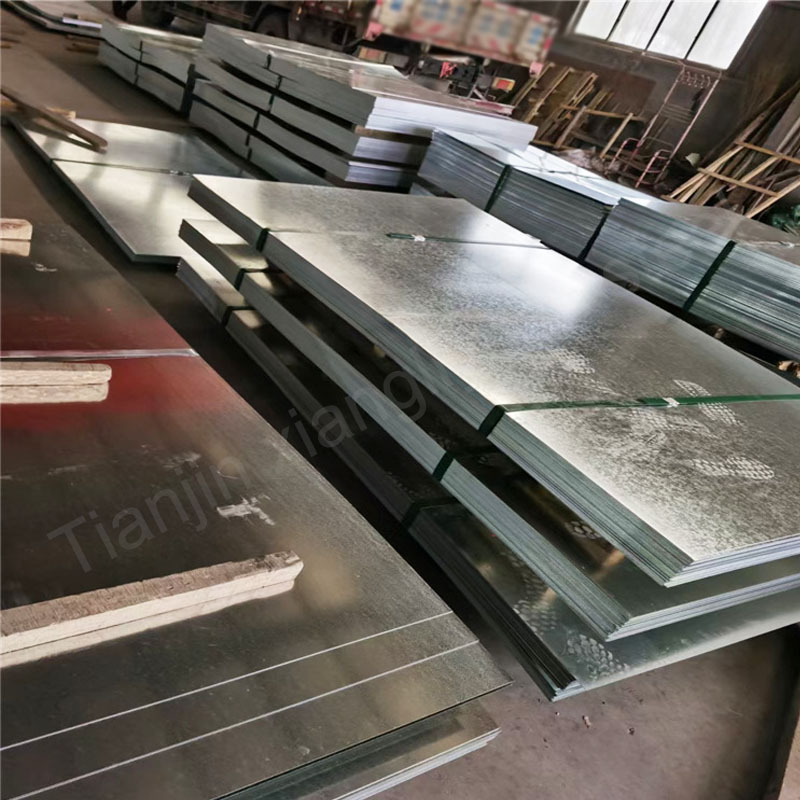

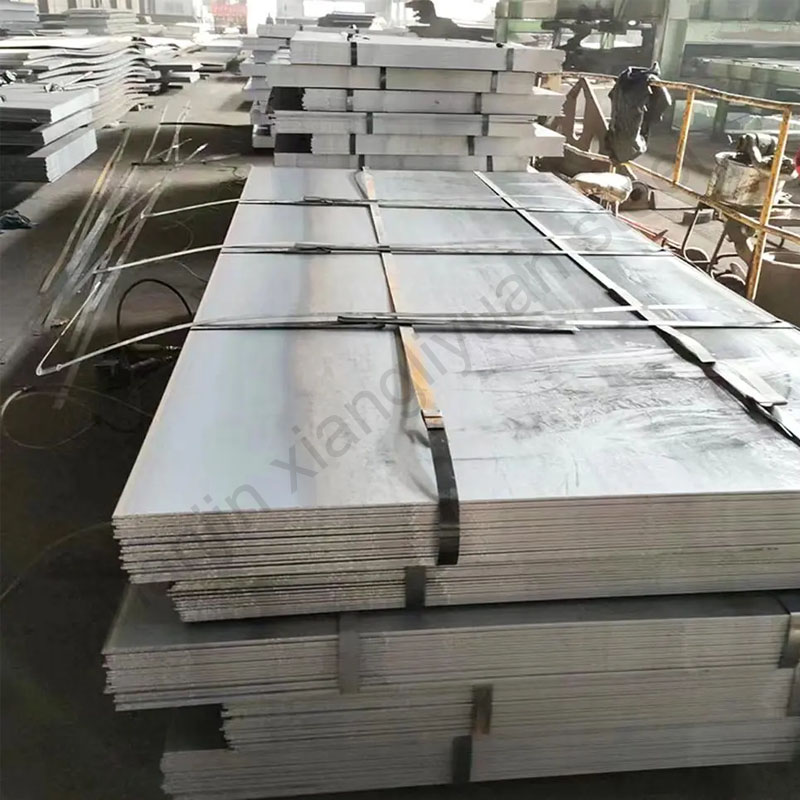

Carbon steel plates are galvanized to improve their corrosion resistance and extend their service life. The zinc coating can effectively prevent oxidation and corrosion on the surface of the steel plate, especially in applications where it is humid or exposed to outdoor environments. Galvanized carbon steel plates are widely used in industries such as construction, automobiles, home appliances, and machinery.

The main processing methods for galvanizing include the following:

Hot-Dip Galvanizing: The carbon steel plate is immersed in a molten zinc bath to cover its surface with a layer of zinc. The galvanized steel plate produced by this method has a thicker coating and stronger corrosion resistance.

Electro-Galvanizing: A layer of zinc is deposited on the surface of the carbon steel plate through an electrolytic process. The coating of electro-galvanizing is thin but uniform, and is usually used in applications with high surface quality requirements.

Mechanical Plating: The carbon steel plate is mixed with zinc powder in a vibrating tank, and the zinc powder is attached to the surface of the steel plate through mechanical action. This method is mainly used for small components and parts of special shapes.

Galvanized steel sheets can be classified as follows:

By coating thickness: they can be divided into thick coating, medium coating and thin coating.

By surface treatment:

they can be divided into ordinary surface treatment and smooth surface treatment, the former is suitable for general use, and the latter is suitable for use with high surface quality requirements.

By steel grade:

according to different strengths and uses, galvanized steel sheets can be divided into ordinary carbon structural steel sheets, high-strength low-alloy steel sheets and structural steel sheets, etc.

The production and quality requirements of galvanized steel sheets usually follow the following standards:

Chinese standards: such as GB/T 2518 “Continuous hot-dip galvanized steel sheets and strips”.

International standards: such as ASTM A653/A653M (American standard), EN 10346 (European standard), JIS G3302 (Japanese standard), etc.

The application fields of galvanized carbon steel sheets are very wide, mainly including:

Construction industry: used for roofs, walls, door and window frames, etc.

Automotive industry: used to manufacture car bodies, chassis, fuel tanks, etc.

Household appliance industry: used for the outer shells of refrigerators, washing machines, air conditioners, etc.

Mechanical manufacturing: used to manufacture mechanical shells, pipes, etc.

Through galvanizing, the durability and service life of carbon steel plates have been significantly improved, and they are widely used in various environments that require corrosion protection.