Wear-resistant steel plate is a high-strength steel made through a special heat treatment process. Its surface hardness can reach HB400-600, which is 3-8 times more wear-resistant than ordinary steel plates. It is widely used in harsh working conditions such as mining machinery and engineering equipment.

Comparison table of mainstream wear-resistant steel plate materials and steel grades

| Country/Brand | Common steel grades | Hardness range | Characteristics comparison |

|---|---|---|---|

| China | NM360/NM400 | HB340-450 | High cost performance, suitable for medium wear |

| Sweden | Hardox400/450 | HB400-470 | Internationally renowned, strong impact resistance |

| Germany | XAR400/XAR500 | HB370-430 | Excellent welding performance |

| Japan | JFE-EH400/500 | HB380-460 | Special for deep-sea equipment |

| USA | AR400/AR500 | HB360-440 | Mainstream choice for construction machinery |

International standards and certification systems

Chinese standards: GB/T 24186-2009 (NM series)

EU certification: EN 10025-4 (S series wear-resistant steel)

USA specifications: ASTM A514/A572 (engineering machinery certification)

Japanese industry: JIS G3106 SM series

Internationally used: ISO 4950 (unified test standard)

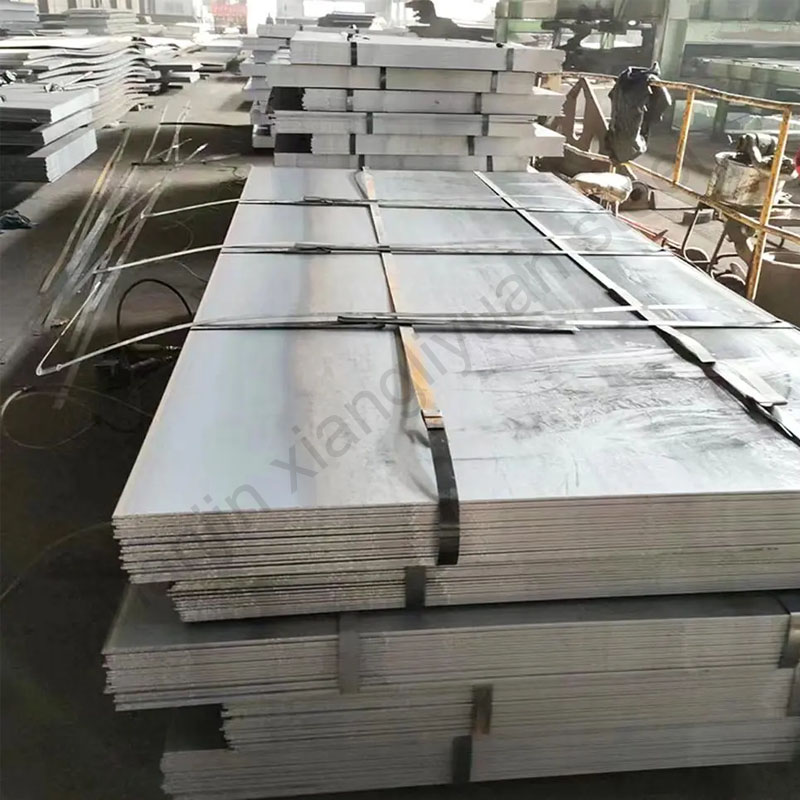

Full analysis of specifications

1. Common thickness specifications

Thin plate series: 6mm/8mm/10mm (conveyor lining)

Regular thickness: 12-50mm (mainstream for excavator buckets)

Ultra-thick customization: 60-120mm (mine crusher cutterhead)

2. Plate size standard

Width range: 1500-2500mm (customizable strips)

Standard length: 6000/8000/12000mm

Special shape: special-shaped cutting parts support laser/water jet processing

Six core application scenarios

Mining

Application parts: crusher lining, vibrating screen beam

Recommended material: Hardox500 + Anti-loosening bolt installation process

Cement production

Key parts: raw material grinding roller sleeve, clinker conveyor trough

Special requirements: additional high temperature resistant coating (≤600℃) is required

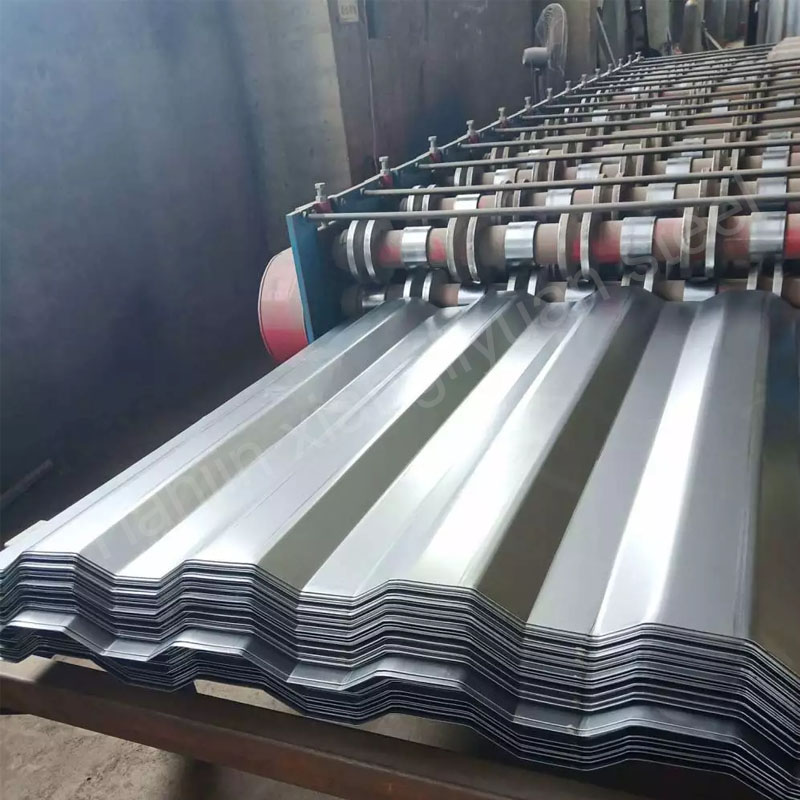

Port machinery

Typical applications: grab blade plate, ship unloader guide rail

Anti-corrosion treatment: HDG hot-dip galvanizing is recommended

Agricultural machinery

Core components: harvester blade, straw crushing bin

Lightweight solution: 8mm thin plate laser grid reinforcement

Electric power

Key equipment: coal mill impact plate, coal conveyor chute

Composite solution: ceramic + steel plate bimetallic composite plate

Special vehicles

Modified applications: dump truck box, bulldozer blade

Welding process: E7018 low-hydrogen welding rod is required

Purchase technical guide

Three key points for quality identification

Hardness test: Use Leeb hardness tester for multi-point detection, surface hardness fluctuation should be ≤5%

Metallographic analysis: martensite content must be >85%, carbide is evenly distributed

Certification documents: MTC material report + CE/PED certification must be provided