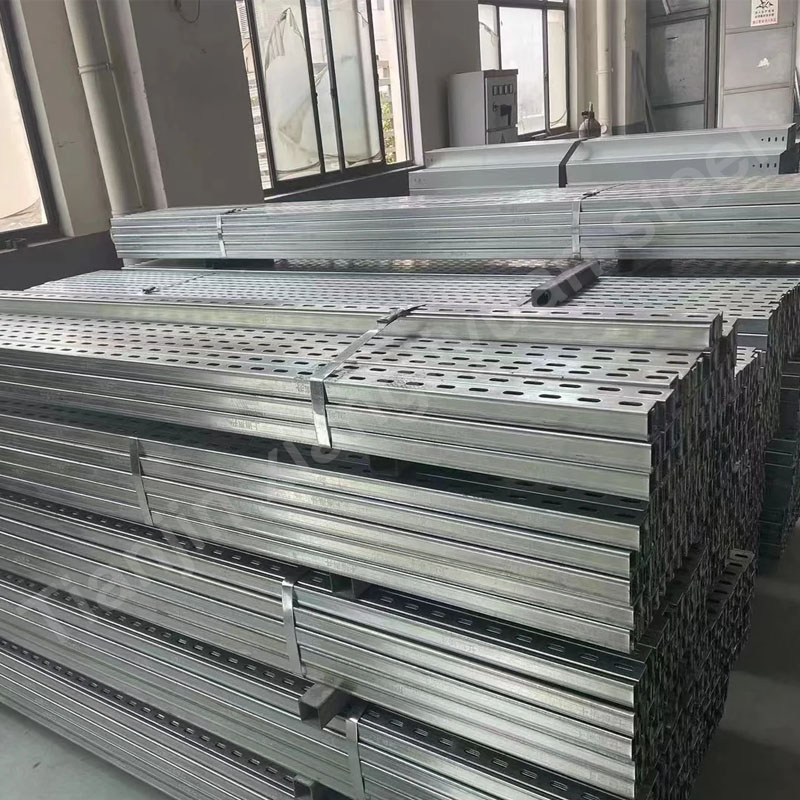

In the demanding world of construction and infrastructure, structural integrity, longevity, and on-time delivery are paramount. As a leading Chinese manufacturer specializing in high-quality Galvanized Steel C-Purlins (C-Sections, C-Channels)-Tianjin xiangliyuan steel, we understand the critical factors international buyers prioritize. We’ve built our reputation on exceeding these expectations, offering not just products, but reliable solutions backed by expertise, flexibility, and unwavering commitment.

Why Galvanized C-Purlins? The Cornerstone of Durability

C-Purlins are the essential skeletal framework for roofs and walls in countless structures – warehouses, factories, agricultural buildings, commercial spaces, and more. Galvanization, the process of applying a protective zinc coating, is non-negotiable for long-term performance. It provides exceptional defense against corrosion, rust, and the damaging effects of harsh weather, chemicals, and UV exposure. Choosing properly galvanized purlins translates directly to:

Decades-Long Service Life: Minimizing maintenance costs and replacement cycles.

Structural Integrity: Maintaining strength and load-bearing capacity over time.

Cost-Effectiveness: Delivering superior value through longevity and reduced downtime.

Aesthetic Consistency: Preserving a clean, professional appearance.

Meeting International Standards: Our Commitment to Quality You Can Trust

We know global clients demand adherence to recognized international specifications. Quality isn’t just claimed; it’s manufactured and verified. Our galvanized C-Purlins consistently meet or exceed the highest global benchmarks:

Material Standards:

ASTM A653 (CS Type B / SS Grade 33/40/80): Widely specified in North America and globally.

EN 10346 (DX51D, DX52D, DX53D + Z275 / Z350): The European standard, demanding specific mechanical properties and coating adherence.

JIS G 3302 (SGCC / SGCH + Z27 / Z35): Common in Asian markets.

AS 1397 (G550 / G500 + Z275 / Z350): Key for Australian and New Zealand projects.

Common Grades: S350GD+Z275 (Equivalent to DX51D+Z275), S550GD+Z275, G550+Z275 – chosen for optimal strength-to-weight ratio and corrosion resistance.

Coating Standards:

ASTM A653 (G60 / G90): Specifying minimum coating weights (e.g., G90 = 0.90 oz/ft² total both sides).

EN 10346 (Z275 / Z350 / Z450): Specifying minimum coating mass in g/m² (e.g., Z275 = 275 g/m² total both sides). Z275 (G90 equivalent) is our most common, premium offering.

Thorough Coating: We ensure complete coverage, including edges and cut ends, for maximum protection. Coating thickness is rigorously monitored.

Dimensional & Tolerancing Standards:

ASTM A924 / A924M: General requirements for metallic-coated steel sheet.

EN 10162: Cold rolled steel sections – Tolerances on dimensions and shape.

JIS G 3350: Light gauge steel sections.

Precision Manufacturing: Our state-of-the-art roll forming lines guarantee consistent profiles, precise angles, and adherence to strict dimensional tolerances (±0.5mm or better on critical dimensions).

Quality Assurance:

Incoming Material Inspection: Verification of steel coil certificates (mill certs) against order requirements.

In-Process Controls: Continuous monitoring of dimensions, coating weight (using XRF gauges), and surface quality.

Final Inspection & Testing: Comprehensive checks before shipment. We provide full Mill Test Certificates (MTCs) or Certificates of Conformity (CoCs) traceable to each batch.

Third-Party Certification: Available upon request to provide independent validation.

Your Specifications, Our Expertise: Unmatched Customization Capabilities

While we stock popular profiles for fast delivery, our true strength lies in flexible customization. We understand your project has unique demands. We manufacture to your exact requirements:

Dimensions:

Flange Width: Commonly from 50mm (2″) up to 300mm (12″) or more.

Web Height: Typically from 100mm (4″) to 300mm (12″), with larger sizes possible.

Lip Size: Custom lip lengths and angles to suit specific cladding or connection needs.

Thickness (Gauge): Ranging from lightweight 1.5mm (16ga / ~0.059″) up to robust 3.5mm (10ga / ~0.135″) or thicker for heavy-duty applications. Popular gauges: 1.8mm (~14ga), 2.0mm (~13ga), 2.3mm (~12ga), 2.6mm (~11ga).

Material & Coating: Select your preferred grade (S350GD, S550GD, etc.) and zinc coating class (Z275/G90 standard, Z350/G120, Z450 for severe environments).

Lengths: Cut-to-length precision, from short sections for transport to long spans minimizing on-site joints. Standard lengths often 6m or 12m, but virtually any length achievable.

Holes & Notches: Pre-punched or slotted holes (round, square, slotted) at precisely specified locations (e.g., 41mm, 82mm centers) for fast, accurate installation. Custom hole patterns welcome.

Packaging: Tailored to your logistics – bulk, bundled, strapped, crated, or palletized for optimal protection and handling efficiency.

Beyond Supply: Empowering Your Success with Purlin Machinery

Unique in the market, we don’t just supply the purlins; we can supply the means to produce them. We design and manufacture high-performance C-Purlin Roll Forming Machines. This offers incredible advantages:

In-House Production: For large-scale, long-term projects, produce purlins on-site, eliminating shipping costs and lead times.

Total Control: Manufacture exactly what you need, when you need it, to your precise specifications.

Business Opportunity: Establish your own purlin manufacturing line to serve your local market.

Full Support: We provide comprehensive machine installation, training, maintenance support, and spare parts.

Speed Without Compromise: Our Delivery Advantage

We understand time is critical. Our optimized manufacturing processes, strategic material sourcing, and efficient logistics network ensure consistently fast lead times, even for customized orders. We excel at handling urgent requirements without sacrificing quality. Our experienced team manages global shipping seamlessly (FOB, CIF, etc.), providing clear communication and documentation every step of the way.

Why Partner With Us? The Definitive Choice for Galvanized C-Purlins

Uncompromising Quality: Rigorous adherence to international standards (ASTM, EN, JIS, AS), certified materials, and stringent QC ensure purlins built to last.

Limitless Customization: No project is too unique. We manufacture precisely to your drawings and specifications.

Competitive Pricing: High-volume manufacturing efficiency in China translates to exceptional value without quality concessions.

Rapid & Reliable Delivery: Streamlined processes and logistics expertise get your purlins on site fast.

Technical Expertise: Decades of experience in purlin design, manufacturing, and application support.

One-Stop Solution: From standard purlins to fully customized profiles, and even the machinery to make them – we cover all bases.

Global Experience: Proven track record of successfully supplying and satisfying international clients worldwide.

Partner with Confidence

When you source Galvanized C-Purlins, you need more than a supplier; you need a reliable partner committed to the success of your project. Our dedication to quality craftsmanship, unparalleled customization flexibility, fast delivery, and unique machinery solutions makes us the definitive choice for contractors, builders, and distributors worldwide.

Looking for top-tier Galvanized C-Purlins manufactured to exacting international standards? Need unique dimensions, specific hole patterns, or exceptional coating? Require lightning-fast delivery for your critical project? Or perhaps you’re exploring in-house production with your own purlin line?

Look no further. Contact us today for a competitive quote, detailed specifications discussion, or to learn more about our purlin machinery solutions. Let us demonstrate why global partners trust us to deliver the structural backbone for their success.