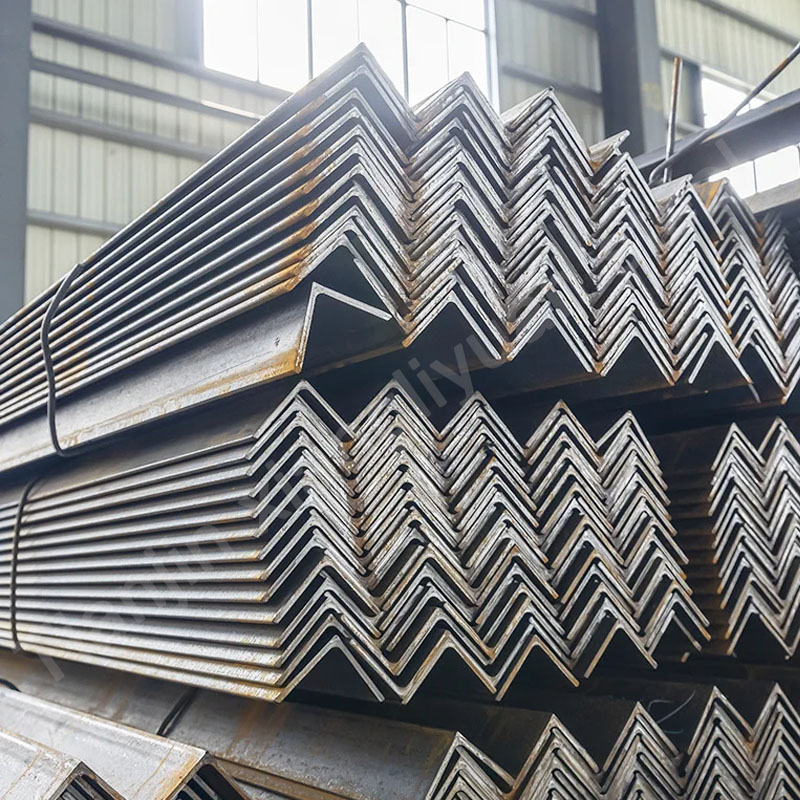

The Global Standard in Angle Steel: Precision, Performance & Partnership

For international buyers sourcing structural components that form the backbone of critical infrastructure, machinery, and construction projects worldwide, the choice of angle steel supplier is paramount. Quality, reliability, versatility, and responsiveness aren’t just preferences – they are essential requirements. As a leading Chinese manufacturer committed to global excellence–Tianjin xiangliyuan steel, we understand these demands intimately. We don’t just produce angle steel; we engineer solutions built on trust, precision, and an unwavering commitment to exceeding your expectations.

Why International Buyers Choose Us: Addressing Your Core Priorities

Uncompromising Material Quality & Consistency:

Prime Materials: We utilize only prime, certified steel billets from reputable mills. Our core materials meet the stringent requirements of internationally recognized standards:

Carbon Steels: ASTM A36 (USA), S235JR, S275JR, S355JR (EN 10025-2 EU), SS400, SS490 (JIS G3101 Japan), Q235B, Q355B (GB/T China – equivalent to S235JR/S355JR). These offer excellent weldability, formability, and strength for general structural applications.

High-Strength Low-Alloy (HSLA) Steels: ASTM A572 Gr 50, S355J2, S355K2 (EN 10025-2), offering superior strength-to-weight ratios for demanding structures.

Stainless Steels (Upon Request): ASTM A276 (304/L, 316/L, etc.) for superior corrosion resistance in harsh environments (food processing, chemical, marine).

Rigorous Quality Control: Every production batch undergoes stringent in-process checks and final inspection. We employ advanced testing equipment (spectrometers, universal testing machines, impact testers) to verify:

Chemical Composition (Conforms precisely to grade specs)

Mechanical Properties (Yield Strength, Tensile Strength, Elongation)

Dimensional Accuracy & Straightness

Full Traceability: Mill Test Certificates (MTCs) or Certificates of Conformity (CoCs), compliant with EN 10204 3.1/3.2 or equivalent, are provided as standard, ensuring complete material traceability and peace of mind.

Comprehensive Range of Standard Sizes & Precise Tolerances:

We stock and produce a vast array of the most commonly requested international dimensions, ready for prompt shipment:

Equal Leg Angles (L): Ranging from small sections like L20x20x3mm (L3/4″x3/4″x1/8″) and L25x25x3mm (L1″x1″x1/8″) up to heavy-duty sections like L150x150x15mm (L6″x6″x9/16″) and L200x200x24mm (L8″x8″x1″).

Unequal Leg Angles (UL): Popular combinations include L100x75x8mm (L4″x3″x5/16″), L150x100x10mm (L6″x4″x3/8″), and L200x150x18mm (L8″x6″x3/4″).

Thicknesses: Typically from 3mm (1/8″) up to 24mm (1″) or more for heavy sections, covering a wide spectrum of load-bearing requirements.

Lengths: Standard lengths are commonly 6 meters (19.7 ft), 9 meters (29.5 ft), and 12 meters (39.4 ft). Custom lengths are a core strength (see below).

Precision Matters: We adhere to tight dimensional tolerances specified in major standards (ASTM A6/A6M, EN 10056, JIS G3192), ensuring legs are straight, angles are true (90°± tolerance), and leg lengths/thicknesses are consistently within spec (±0.8mm to ±2mm typically, depending on size and standard). Consistent cross-sectional properties are guaranteed.

Adherence to Global Standards & Certifications:

Our manufacturing processes and final products consistently comply with the rigorous requirements of international standards, including:

ASTM (USA): A36, A572, A529, A709, A6/A6M (General Requirements)

EN (European): EN 10025-2 (Structural Steels), EN 10056-1 (Specifications for Hot Rolled Equal & Unequal Angles)

JIS (Japanese): JIS G3101 (SS Series), JIS G3192 (Dimensions, Mass, Tolerances)

ISO (International): ISO 9001:2015 (Quality Management Systems – Certified) underpins our entire operation.

GB/T (China): GB/T 706 (Hot Rolled Section Steel – Dimensions/Shape/Weight/Tolerances), GB/T 700 (Carbon Structural Steels – Q235B), GB/T 1591 (HSLA Steels – Q355B).

Third-Party Verification: We readily facilitate third-party inspections (SGS, BV, Lloyds, etc.) and provide all necessary documentation for smooth customs clearance and project compliance.

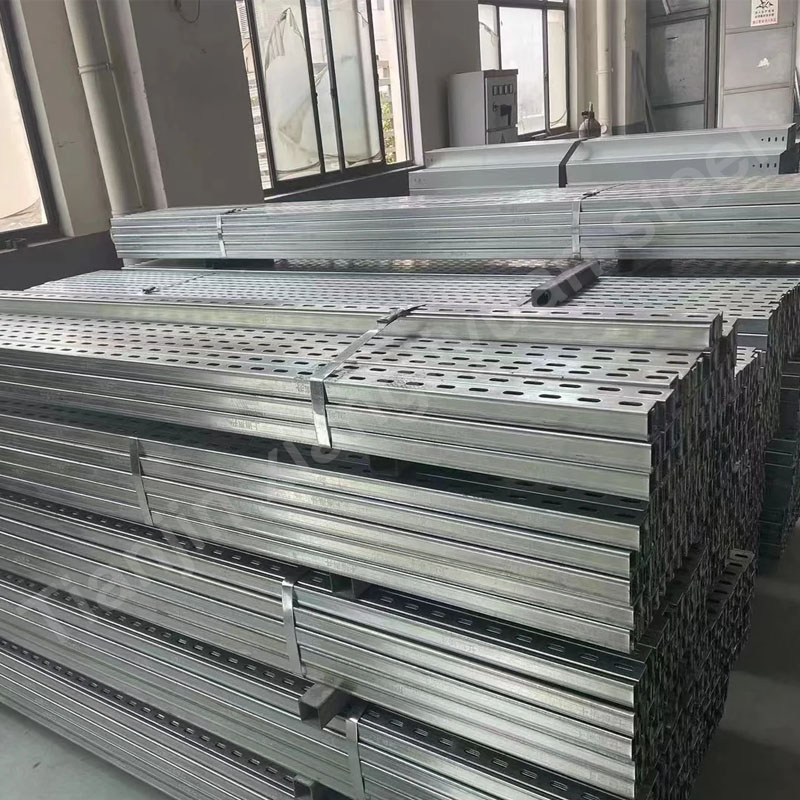

Unmatched Customization Capabilities:

Beyond our extensive standard catalog, customization is our hallmark. We excel at producing angles tailored to your unique project needs:

Non-Standard Dimensions: Require a specific leg length combination (e.g., L130x80x6mm) or a thickness outside typical ranges? We can roll it.

Special Lengths: Need angles cut precisely to 5.8m, 7.5m, 15m, or even 18m (59 ft),We can supply exact lengths, minimizing waste and secondary processing on your end.

Special Tolerances: Projects demanding tighter-than-standard dimensional tolerances? We adjust our processes to meet your precision requirements.

Special Material Grades: Requiring specific chemical compositions or mechanical properties not covered by standard grades? We work with you and our mill partners to source or produce it.

Special Finishes: While standard is mill scale, we can arrange shot blasting, priming, or other surface preparations upon request.

Collaborative Engineering: Our technical team partners with you to understand your application and ensure the custom solution meets both functional and budgetary requirements.

Competitive Pricing & Exceptional Value:

Leveraging efficient large-scale production, optimized logistics, and strategic sourcing in China, we offer highly competitive pricing without compromising on quality or service. We deliver true value – premium angle steel at cost-effective rates.

Reliable, Fast Delivery – Your Timeline is Our Priority:

Standard Stock: Popular sizes and grades are often available in our warehouse for immediate shipment.

Efficient Production: Our modern rolling mills and streamlined processes enable rapid turnaround times for both standard and custom orders.

Global Logistics Expertise: We have extensive experience managing international shipments. We handle documentation efficiently and partner with reliable freight forwarders to ensure your order reaches its destination fast and securely, whether by sea (FCL/LCL), air, or land. Expect significantly shorter lead times compared to many competitors – we understand time is critical.

Beyond the Product: The Partnership Advantage

Choosing us means more than just buying angle steel; it’s about securing a reliable, responsive partner dedicated to your success:

Technical Support: Our experienced team provides guidance on material selection, specifications, and application suitability.

Responsive Communication: Clear, timely communication in English throughout the quotation, order, production, and shipping process.

Flexible Order Quantities: We cater to both large project requirements and smaller, specialized orders.

Secure Packaging: Angles are bundled robustly using steel strapping to prevent damage during transit, ensuring they arrive in perfect condition.

Your Trusted Global Source for Premium Angle Steel

In the demanding world of international construction, manufacturing, and infrastructure, you need an angle steel supplier you can rely on absolutely – for consistent, certified quality, the exact specifications you require (standard or custom), and delivery that keeps your projects on schedule.

We stand firmly behind our products with rigorous quality control, adherence to global standards, and a deep commitment to customer satisfaction. Our extensive manufacturing capabilities and logistical efficiency translate directly into tangible benefits for you: superior product performance, project flexibility, cost savings, and peace of mind.

Don’t settle for less. Experience the difference that a truly dedicated, high-performance angle steel partner can make.

Ready to discuss your specific requirements? Contact our international sales team today for a competitive quote and discover how we can streamline your supply chain and contribute to the success of your next project. We are confident that once you try us, you’ll make us your go-to source for all your angle steel needs.