Choosing the correct steel pipe is a critical decision impacting the safety, cost, and longevity of any project. The core of this decision lies in understanding the intrinsic properties of the pipe material itself. At Tianjin Xiangliyuan Steel, we specialize in manufacturing pipes from a range of materials, each engineered to deliver specific advantages for distinct industrial challenges. This guide focuses on the essential material characteristics and the concrete benefits they provide, helping you make an informed selection.

Core Material Classes and Their Inherent Advantages

1. Carbon Steel Pipes: The Backbone of Industry

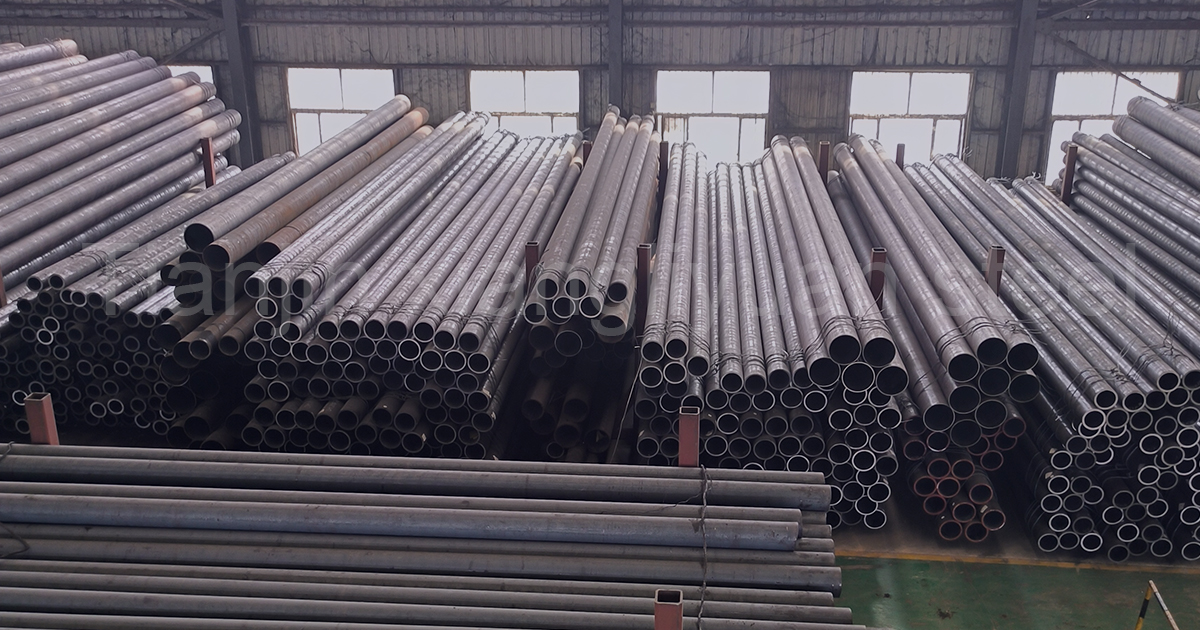

Carbon steel, an alloy of iron and carbon, is the most widely used material for piping due to its exceptional versatility and cost-effectiveness.

Key Advantages:

High Strength & Durability: Offers excellent tensile and yield strength, making it capable of withstanding high internal pressures and heavy structural loads. Pipes like ASTM A106 Grade B and API 5L Grade B are industry standards for demanding applications.

Excellent Machinability & Weldability: Carbon steel is relatively easy to cut, bend, and weld using common methods, reducing fabrication time and costs on-site.

Cost-Efficiency: Provides the best balance of performance and cost, making it the economical choice for large-scale projects in construction, plumbing, and general fluid transport.

Wide Temperature Range: Suitable for many services from low to moderately high temperatures, especially when normalized or stress-relieved.

Our Common Grades: ASTM A53 (A,B), ASTM A106 (A,B,C), API 5L (PSL1 & PSL2 from B to X70), ASTM A500 (for structural tubing).

2. Stainless Steel Pipes: The Champion of Corrosion Resistance

Stainless steel pipes, containing a minimum of 10.5% chromium, form a passive oxide layer that protects against rust and corrosion.

Key Advantages:

Superior Corrosion Resistance: The primary advantage. Resists attack from water, chemicals, acids, and chlorides. Grade 304 is excellent for general use, while Grade 316, with added molybdenum, provides enhanced resistance to pitting in saline or chloride-rich environments.

Hygienic & Easy-Clean Surface: The non-porous, smooth surface prevents bacterial buildup and is easy to sterilize, making it mandatory in food & beverage, pharmaceutical, and medical gas systems.

High-Temperature Strength: Maintains its strength and oxidation resistance at elevated temperatures better than carbon steel, ideal for heat exchangers and exhaust systems.

Aesthetic Appeal: Offers a clean, modern look for architectural and visible applications like handrails and decorative structures.

Our Common Grades: ASTM A312 TP304/304L, TP316/316L, TP321, and Duplex 2205 for even higher strength and corrosion resistance.

3. Alloy Steel Pipes: Engineered for Enhanced Properties

Alloy steels incorporate additional elements like chromium, molybdenum, and vanadium to achieve specific performance enhancements beyond basic carbon steel.

Key Advantages:

Enhanced Strength & Toughness: Elements like manganese and chromium increase hardenability and strength without significantly compromising ductility.

Improved Temperature Performance: Grades like ASTM A335 P11, P22, P91 are specifically designed for high-temperature service in power plants and refineries, offering excellent creep resistance.

Better Corrosion & Wear Resistance: Specific alloys offer improved resistance to oxidation, sulfidation, and abrasion compared to standard carbon steel.

4. Galvanized Steel Pipes: Carbon Steel with a Protective Shield

These are carbon steel pipes that have been coated in a layer of zinc through a hot-dip process.

Key Advantages:

Economic Corrosion Protection: The zinc coating acts as a sacrificial barrier, protecting the underlying steel from rust, especially in outdoor or humid environments. It provides a long service life at a lower cost than stainless steel.

Robust & Durable: The metallurgical bond between the zinc and steel creates a tough coating resistant to mechanical damage.

Ideal for Standard Applications: The go-to solution for water supply lines, fencing, scaffolding, and structural applications exposed to the elements.

Material Selection Guide: Matching Advantage to Application

| Application Area | Primary Requirement | Recommended Material | Key Advantage Utilized |

|---|---|---|---|

| Oil & Gas Pipelines | High Strength, Pressure Integrity | API 5L X52-X70 Carbon Steel | High yield strength, excellent weldability for long-distance integrity. |

| Structural Frameworks | Load-bearing Capacity, Cost | ASTM A500 Carbon Steel / Galvanized | High strength-to-weight ratio, economic durability. |

| Process Plants (Chemical) | Corrosion Resistance | Stainless Steel 316/316L | Resistance to aggressive chemicals and pitting corrosion. |

| Power Plant Boilers | High-Temperature Strength | Alloy Steel (A335 P11, P22) | Creep resistance and strength at elevated temperatures. |

| Water Transmission | Corrosion Resistance, Cost | Galvanized Steel (A53) | Long-term protection against water corrosion economically. |

| Food Processing Lines | Hygiene, Cleanability | Stainless Steel 304 | Non-toxic, easy-to-clean surface, prevents contamination. |

| Hydraulic Systems | Precision, Strength | Cold Drawn Seamless (CDS) Carbon Steel | Excellent surface finish, tight tolerances, high pressure rating. |

The Tianjin Xiangliyuan Steel Advantage: Consistency in Every Pipe

Our commitment is to deliver the inherent advantages of each material consistently, pipe after pipe.

Material Sourcing & Verification: We source raw materials from reputable mills and perform stringent incoming inspection, including spectrographic analysis, to ensure chemistry meets exact grade specifications.

Process-Controlled Manufacturing: Whether producing seamless pipes for homogenous strength or ERW/HFI welded pipes for dimensional consistency, our processes are calibrated to preserve and enhance the material’s properties.

Comprehensive Testing: Every batch is validated through tensile tests, hardness tests, hydrostatic tests, and non-destructive inspection. This guarantees that the advantages promised by the material specification are fully realized in the final product.

Full Traceability: Each pipe is documented with a Mill Test Certificate (MTC), providing you with verified proof of material properties and compliance with ASTM, API, EN, and other international standards.

Selecting for Performance and Value

The choice of pipe material is a direct investment in the performance and lifecycle cost of your project. By understanding the fundamental advantages of carbon steel, stainless steel, alloy steel, and galvanized coatings, you can specify with confidence.

Tianjin Xiangliyuan Steel provides not just the material, but the guaranteed performance that comes with it. We offer the technical expertise to help you navigate this selection, ensuring you receive the optimal pipe that delivers strength, corrosion resistance, durability, and value for your specific application.

For detailed material data sheets, technical consultation on material selection, or to request a quote for your project requirements, please contact our team.

Email: infosteel@xlygt.com

Tianjin Xiangliyuan Steel – Your Reliable Source for Performance-Driven Steel Pipes.