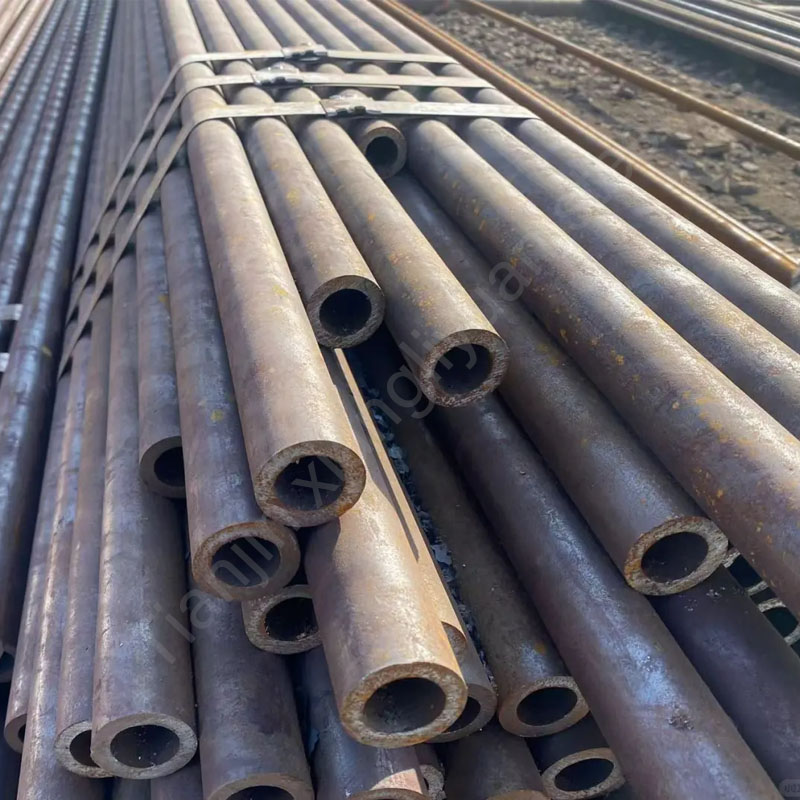

Seamless steel pipe is a pipe with a hollow cross-section and no seams around it. It is made by hot rolling, cold rolling or cold drawing. Due to its excellent mechanical properties and pressure resistance, it is widely used in petroleum, chemical, electric power, machinery manufacturing and other fields.

1. Classification by material

The material of seamless steel pipe directly affects its mechanical properties, corrosion resistance and applicable scenarios. Common material classifications are as follows:

1. Carbon steel seamless steel pipe

Carbon steel is the most widely used seamless steel pipe material. Its main components are iron and carbon, with a carbon content of 0.06%~1.7%. According to the carbon content, it can be divided into:

Ordinary carbon steel (such as Q235): moderate strength, low cost, commonly used in building structures, ordinary fluid transportation (such as water, air).

High-quality carbon steel (such as 20#, 45#): less impurities such as sulfur and phosphorus, better mechanical properties, suitable for mechanical parts (such as shafts, gears) and low-pressure boiler tubes.

2. Alloy steel seamless steel pipe

Adding alloy elements such as chromium, molybdenum, and nickel to carbon steel to improve high temperature resistance, corrosion resistance or high strength performance, mainly divided into:

Low alloy steel (such as 16Mn, 15CrMo): adding a small amount of alloy elements, the strength is significantly improved, used for high-pressure containers, bridge structures, etc.

High alloy steel (such as 304H, 316L): high alloy element content, strong corrosion resistance, suitable for chemical equipment, nuclear power plant pipelines.

3. Stainless steel seamless steel pipe

With chromium and nickel as the main alloy elements, it has excellent corrosion resistance and aesthetics. According to the metallographic structure, it can be divided into:

Austenitic stainless steel (such as 304, 316): resistant to acid and alkali corrosion, used in food processing and medical equipment.

Ferritic stainless steel (such as 430): good oxidation resistance, low cost, mostly used for decorative pipes and automobile exhaust systems.

Duplex stainless steel (such as 2205): has both strength and corrosion resistance, suitable for marine engineering and petrochemical industry.

4. Seamless steel pipes made of special materials

Low-temperature steel (such as 09MnNiDR): Remains tough below -40°C and is used for liquefied natural gas (LNG) storage and transportation equipment.

Heat-resistant steel (such as 12Cr1MoVG): Can be used for a long time at high temperatures above 600°C, commonly used in power station boilers and heat exchangers.

2. Classification by standards

The production and use of seamless steel pipes must comply with domestic and international standards. Different standards correspond to different technical requirements and application scenarios:

1. International standards

ASTM standards (American Society for Testing and Materials)

ASTM A106: Carbon steel seamless pipes for high temperatures,

ASTM A335: Chromium-molybdenum alloy steel pipes, used in high temperature and high pressure environments (such as power station boilers).

DIN standards (German industrial standards)

DIN 17175: High-pressure boiler pipes suitable for thermal power plants.

JIS standards (Japanese industrial standards)

JIS G3454: Carbon steel and molybdenum alloy steel pipes, used for mechanical structural parts.

2. Domestic standards

GB/T standard (China national standard)

GB/T 8163: Seamless steel pipes for fluid transportation, widely used in water, oil and gas pipelines.

GB 9948: Seamless pipes for petroleum cracking, resistant to high temperature and high pressure, suitable for oil refining units.

YB/T standard (metallurgical industry standard)

YB/T 5035: Seamless steel pipes for automobile half-axle casings, emphasizing high strength and fatigue resistance.

3. Industry-specific standards

API standard (American Petroleum Institute)

API 5CT: Oil well casing and tubing, requiring anti-crushing and anti-corrosion, used for oil and gas production.

API 5L: Line pipe, used for onshore and submarine oil and gas transportation.

EN standard (European standard)

EN 10216: Seamless steel pipes for pressure equipment, covering a variety of working conditions such as high temperature and low temperature.

3. Main application areas of seamless steel pipes

According to the combination of materials and standards, the application scenarios of seamless steel pipes can be summarized into the following categories:

Energy industry

Oil drills use API 5CT casing, which is resistant to high pressure and hydrogen sulfide corrosion.

Thermal power plants use ASTM A213 alloy steel pipes to withstand high-temperature steam.

Chemical equipment

316L stainless steel pipes are used for the transportation of highly corrosive media (such as hydrochloric acid and nitric acid).

Machinery manufacturing

45# carbon steel precision cold-drawn pipes are used for hydraulic cylinders to ensure dimensional accuracy and surface finish.

Transportation

Automobile exhaust systems use 409 ferritic stainless steel pipes, which are resistant to high-temperature oxidation.

Construction engineering

Q235 structural pipes are used for large-span steel structure supports such as gymnasiums and airports.

Seamless steel pipes have become an indispensable basic material for modern industry due to their diverse materials and strict standard system. In the future, with the development of high-end equipment manufacturing and new energy industries, the demand for high-performance, special material seamless pipes will continue to grow.