Flat steel is a type of steel with a width greater than its thickness. It is usually supplied in rectangular cross-sections, and a small number of them are supplied in trapezoidal cross-sections. Flat steel can be supplied in coils (strip steel) or cut-to-length plates, and is an important material in the industrial and construction fields.

Flat steel can be made of a variety of steel materials, common materials are:

Carbon steel: ordinary carbon structural steel (such as Q235), high-quality carbon structural steel (such as 45 steel).

Alloy steel: such as low-alloy high-strength structural steel (such as Q345), used in structures that require higher strength.

Stainless steel: such as 304 and 316 stainless steel, used in situations requiring corrosion resistance.

The following are some common steel grades:

Ordinary carbon structural steel: such as Q195 and Q235.

High-quality carbon structural steel: such as Q345, 20Mn, and 45 steel.

Alloy structural steel: such as 20Cr, 40Cr, and 30Mn2.

Stainless steel: such as 304 and 316.

Flat steel can be classified in many ways according to its production process, material and purpose.

1. Classification by production process

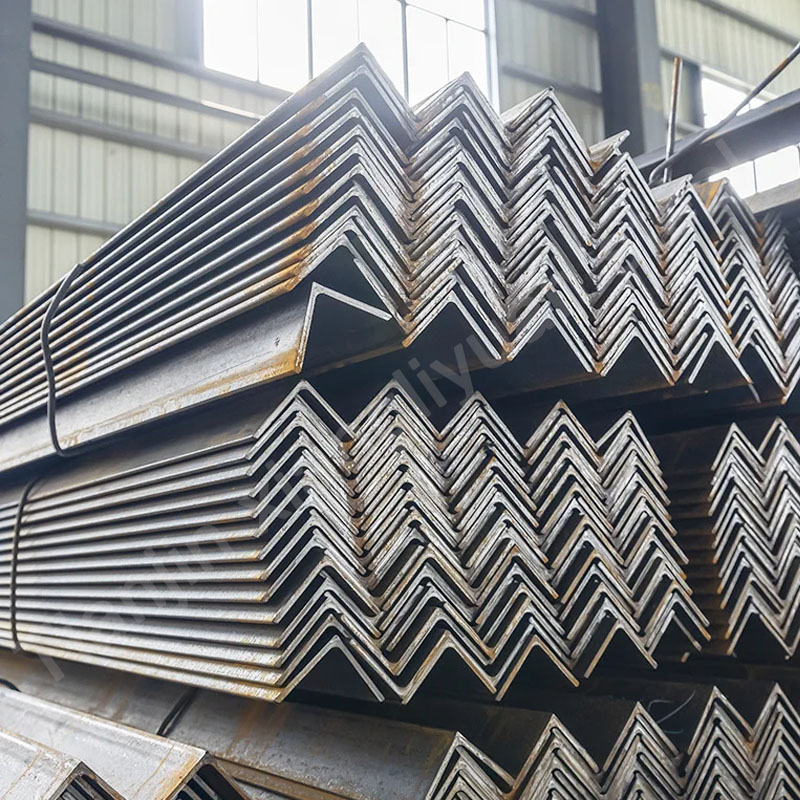

Hot-rolled flat steel: produced by hot rolling process, after high temperature rolling, with iron oxide scale on the surface, and large dimensional tolerance. Mainly used in structural engineering such as buildings and bridges.

Cold-rolled flat steel: produced by cold rolling process, after rolling at room temperature, with smooth surface and high dimensional accuracy. It is mostly used in fields requiring high surface quality and accuracy such as machinery manufacturing and home appliance housing.

2. Classification by material

Carbon steel flat steel: made of ordinary carbon structural steel, such as Q235 and Q195, widely used in general structures and construction projects.

Alloy steel flat steel: contains a certain amount of alloy elements, such as Q345 and 16Mn, used for structures that withstand high stress and have special performance requirements.

Stainless steel flat steel: made of stainless steel materials, such as 304 and 316, with good corrosion resistance, mostly used in chemical, food, pharmaceutical and other industries.

3. Classification by shape

Flat steel: rectangular in cross section, with right-angled edges, it is the most widely used, mainly for structural parts, frames, etc.

Round-edge flat steel: rectangular in cross section, but with rounded edges, usually used in places with high aesthetic and safety requirements.

4. Classification by use

Structural flat steel: mainly used in building structures, such as steel structure beams, bridge components, frames, etc.

Mechanical flat steel: used to manufacture mechanical parts, such as machine tool guides, equipment foundations, etc.

Special flat steel: flat steel with specific properties or used in specific fields, such as weathering steel flat steel and stainless steel flat steel.

5. Classification by delivery status

Hot-rolled delivery: flat steel is delivered directly after hot rolling, with a rough surface and iron oxide scale.

Pickling delivery: after pickling treatment, the surface iron oxide scale is removed, and the surface finish is high.

Cold-rolled delivery: after cold rolling, the surface is smooth and the dimensional accuracy is high.

The standards for flat steel cover the product specifications, performance, chemical composition and inspection methods. The following are several common flat steel standards:

1. GB/T 702-2008 “Dimensions, shape, weight and allowable deviation of hot-rolled flat steel”

Applicable to hot-rolled flat steel, which specifies the dimensions, tolerances, shapes, weights and allowable deviations of hot-rolled flat steel. It is an important reference standard for the size and appearance quality of flat steel.

2. GB/T 706-2008 “Hot-rolled bars and plates for structural steel”

This standard includes the specifications and technical conditions of hot-rolled flat steel and steel plates, mainly used for flat steel and steel plates for structural purposes, and specifies the performance and inspection requirements of the products.

3. GB/T 1591-2018 “Low-alloy high-strength structural steel”

Applicable to low-alloy high-strength structural steel, including flat steel of grades such as Q345, and suitable for building structures that require higher strength and weather resistance.

4. GB/T 2101-2017 “General Provisions for Acceptance, Packaging, Marking and Quality Certificate of Steel Shapes”

Applicable to the requirements for acceptance, packaging, marking and quality certificates of various steel shapes (including flat steel), and provides unified requirements and specifications for flat steel delivery.

5. GB/T 709-2016 “Dimensions, Shapes, Weights and Permissible Deviations of Hot-rolled Steel Plates and Strips”

This standard applies to hot-rolled steel plates and strips. Although it is not specifically for flat steel, it also serves as a reference for the dimensions and tolerances of hot-rolled steel plates, especially in the production of flat steel in strip form.

6. GB/T 3274-2017 “Hot-rolled Thick Steel Plates and Strips of Carbon Structural Steel and Low-alloy Structural Steel”

Applicable to hot-rolled thick steel plates and strips, used to manufacture flat steel products for mechanical parts, welded structures and general structural parts.

7. GB/T 24511-2017 Weathering Structural Steel

This standard applies to weathering structural steel, including weathering flat steel products, especially for buildings such as bridges and towers that are exposed to outdoor environments for a long time.

8. ASTM A36/A36M

American standard for carbon structural steel, including hot-rolled flat steel. Applicable to a wide range of engineering structures, such as bridges and building frames.

9. JIS G3192:2014

Japanese standard that specifies the shape, size, weight and allowable deviation of hot-rolled flat steel, widely used in the Asian market.

Flat steel is widely used in various industries due to its unique shape, material and diverse specifications:

1. Building structure

Steel structure engineering: used for steel structure frames, columns, beams, stairs and other components, and is one of the skeleton materials of buildings.

Bridge construction: used for load-bearing structures such as crossbeams, longitudinal beams, and bridge decks of bridges.

Infrastructure: widely used in the steel structure parts of infrastructure such as hydropower stations, ports, airports, and railways.

2. Machinery Manufacturing

Machinery parts: used to manufacture parts of various mechanical equipment, such as machine tool guide rails, mechanical brackets, gear boxes, etc.

Equipment foundation: used for equipment base and frame structure to provide support for large machinery and equipment.

3. Shipbuilding

Hull structure: used to manufacture ship skeletons, decks, bulkheads and other structural parts. Due to its corrosion resistance and high strength, it is particularly suitable for the ship field.

Marine engineering: widely used in offshore platforms, docks, pontoons and other structures that need to withstand seawater corrosion.

4. Automobile industry

Automobile chassis: used to manufacture automobile chassis, frames, support structures and other load-bearing parts.

Auto parts: used to manufacture some key body parts, such as bumper brackets, door frames, etc.

5. Home appliance manufacturing

Home appliance shell: used for the shell structure of home appliances such as refrigerators, washing machines, air conditioners, etc., especially cold-rolled and stainless steel flat steel.

Internal components: used for the support structure, heat sink, etc. inside home appliances.

6. Metal products

Tools and molds: used to manufacture various types of tools, molds and knives, especially in situations where high hardness and wear resistance are required.

Handrails and guardrails: used for decorative and safety parts such as handrails and railings inside and outside buildings.

7. Chemical equipment

Chemical containers: used to manufacture containers, pipelines, reactors, etc. in chemical equipment, especially stainless steel flat steel is suitable for corrosive environments.

Conveying equipment: used for conveyor belt brackets, equipment frames, etc. in the chemical industry.

8. Other applications

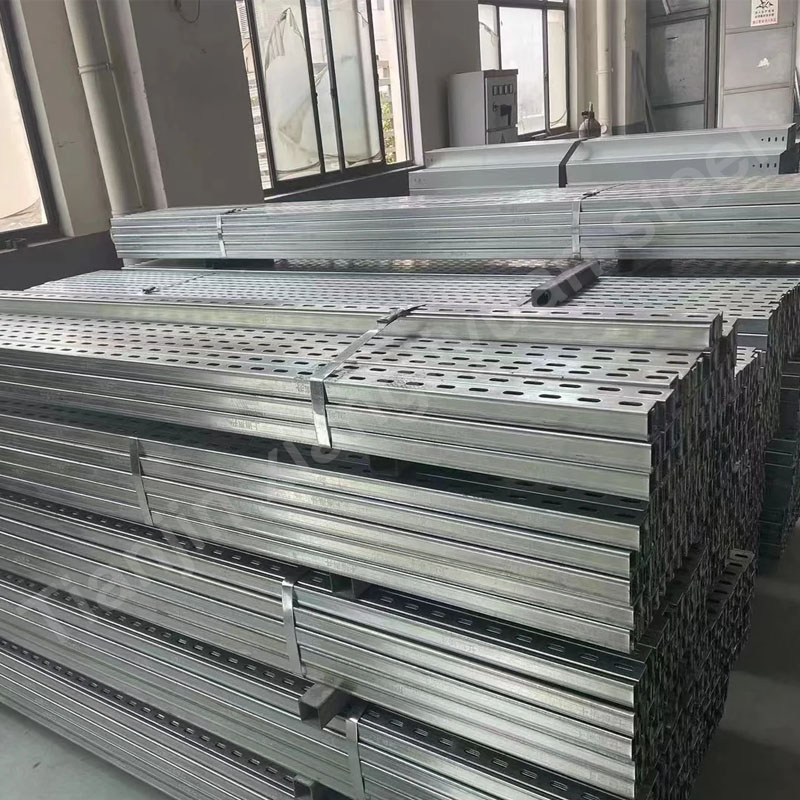

Power engineering: used to manufacture cable brackets, cable trays and other structural parts of substations.

Decorative materials: used in building decoration as door and window frames, exterior wall decorative panels, curtain wall structures, etc.

In short, flat steel is widely used in many industries because of its easy processing, high structural strength and material diversity.