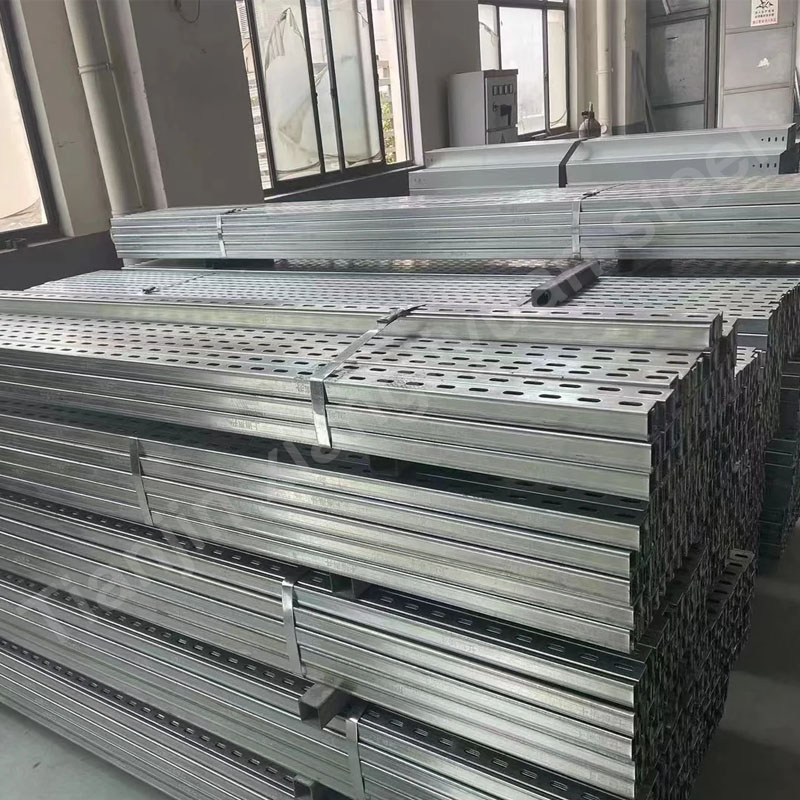

C-shaped steel is a cold-bent steel, named after its cross-sectional shape similar to the letter “C”. C-shaped steel is widely used in construction, machinery manufacturing, vehicle manufacturing, solar brackets and other fields due to its excellent mechanical properties and economy.

C-shaped steel generally uses hot-rolled or cold-rolled steel strip as raw material. Common materials include Q235, Q345, Q195, Q215, SS400, etc. The choice of specific materials depends on the application scenario and needs.

Q235: This steel material has good comprehensive performance, good plasticity and toughness, and is easy to weld. It is the most commonly used ordinary carbon structural steel.

Q345: This steel material is a low-alloy high-strength structural steel with high strength and good impact resistance. It is suitable for occasions with high strength requirements.

C-shaped steel is mainly processed by cold bending process, that is, the steel strip is bent into a “C” cross-section through a rolling equipment. There are two main processing methods:

Cold bending forming: hot-rolled or cold-rolled steel plates are gradually bent into a C shape through multiple rollers. The C-shaped steel produced in this way has high precision, and different specifications of C-shaped steel can be produced by adjusting the configuration of the rollers.

Hot rolling forming: Steel is formed by rollers at high temperature, usually used to produce C-shaped steel of larger specifications or thickness.

According to the use and appearance, C-shaped steel can be classified as follows:

Standard C-shaped steel: The most common type of C-shaped steel, widely used in building structures.

Edged C-shaped steel: On the basis of standard C-shaped steel, edges of a certain width are added on both sides to increase its bending and torsion resistance.

Galvanized C-shaped steel: The surface is galvanized and has strong anti-corrosion properties, suitable for outdoor or humid environments.

Common steel grades of C-shaped steel:

Q235B: Yield strength ≥ 235MPa, suitable for structures with general strength requirements.

Q345B: Yield strength ≥ 345MPa, suitable for structures with higher strength requirements.

SS400: Yield strength ≥ 245MPa, commonly used in welded structures.

The production and use of C-shaped steel are subject to a number of standards and specifications. The main standards are:

1. GB/T 6725-2008 “Cold-bent thin-walled steel”

Scope of application: Applicable to various types of cold-bent thin-walled steel, including C-shaped steel.

2. GB/T 6723-2008 “Dimensions, shapes, weights and allowable deviations of cold-bent steel”

Scope of application: Applicable to the production and inspection of cold-bent steel to ensure the dimensional accuracy and consistency of the product.

3. GB/T 700-2006 “Carbon structural steel”

Scope of application: Used for the material selection of C-shaped steel, especially Q235 series steel.

4. GB/T 1591-2018 “Low-alloy high-strength structural steel”

Scope of application: Applicable to C-shaped steel materials with higher strength, such as Q345 series.

5. GB/T 2518-2008 “Continuous hot-dip galvanized steel sheets and strips”

Scope of application: Applicable to the production and inspection of galvanized C-shaped steel to ensure its anti-corrosion performance.

6. GB/T 13793-2008 “Cold-formed Hollow Steel”

Scope of application: Involves cold-formed C-shaped steel used in buildings and machinery.

7. JG/T 137-2001 “Technical Specifications for Cold-formed Thin-walled Steel Structures”

Scope of application: Applicable to cold-formed thin-walled steel, including the application of C-shaped steel in building structures.

8. ASTM A653/A653M-2019 “Standard Specification for Galvanized Steel Sheets and Strips”

Scope of application: One of the standards adopted for export products or international projects.

The application field of C-shaped steel is very wide, mainly including:

Building structure: used for beams, columns, purlins, walls, etc. in light steel structure buildings.

Machinery manufacturing: used to manufacture frames, brackets, rails, etc. for mechanical equipment.

Solar brackets: widely used in solar photovoltaic brackets.

Vehicle manufacturing: used to manufacture carriages, frames, truck side panels, etc.

Storage shelves: used to manufacture various storage shelves and industrial shelves.

In summary, C-shaped steel is a multi-purpose profile, which is widely used in various industrial fields due to its good performance and diverse material selection.