Galvanized corrugated steel sheet is a corrugated steel sheet with a galvanized surface. It has good corrosion resistance and mechanical strength and is widely used in building roofs, walls, fences and other fields.

Production process of galvanized corrugated steel sheet

Raw material preparation: Select high-quality cold-rolled steel coils or hot-rolled steel coils as the substrate.

Pickling: The steel coils are pickled to remove the oxide scale and impurities on the surface.

Cold rolling or hot rolling: The steel coils are cold-rolled or hot-rolled as needed to obtain steel sheets of the required thickness.

Galvanizing: The steel sheet is subjected to hot-dip galvanizing or electro-galvanizing process to form a uniform zinc layer to improve corrosion resistance.

Hot-dip galvanizing: The steel sheet is immersed in a molten zinc tank so that its surface is evenly covered with a zinc layer.

Electro-galvanizing: Zinc ions are deposited on the surface of the steel sheet through an electrolytic process.

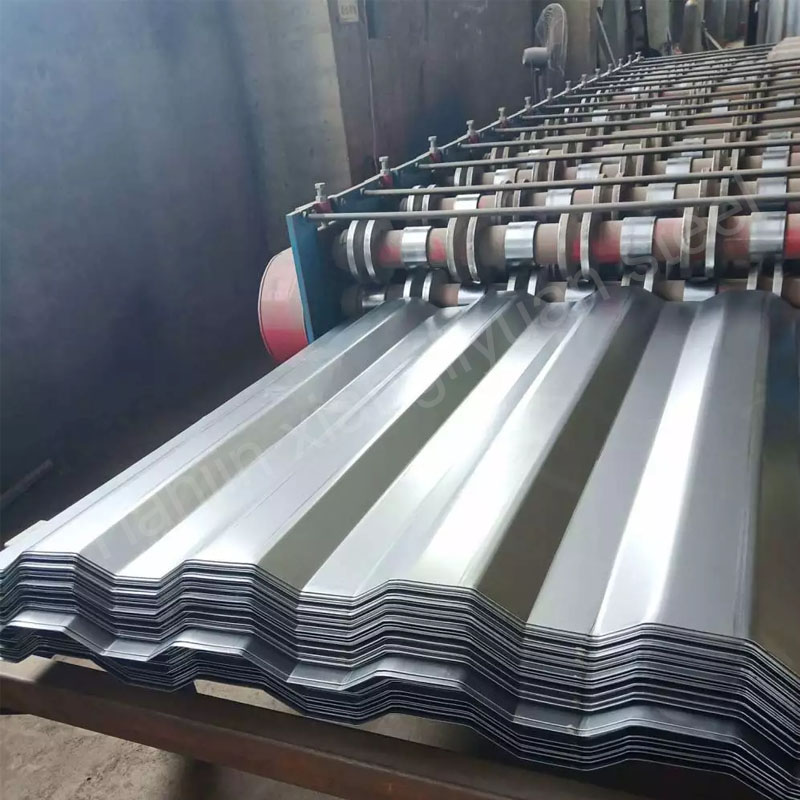

Forming: The galvanized steel sheet is processed by a corrugated forming machine and pressed into corrugated sheets of different shapes such as wavy or trapezoidal.

Shearing: Shear into corrugated sheets of specified length as needed.

Surface treatment: passivation, oiling or coating can be performed as needed to improve rust resistance.

The base material of galvanized corrugated steel sheet is generally carbon steel, and the specific materials include:Q195, Q235, SPCC, SGCC

According to different application requirements, the steel grades of galvanized corrugated steel sheets are mainly divided into the following categories:

Commercial quality (CQ)

Forming quality (FQ)

Drawing quality (DQ)

Structural quality (SQ)

The production and application of galvanized corrugated steel sheet have corresponding international and national standards, mainly including:

ASTM A653/A653M: American Society for Testing and Materials standard, which specifies the requirements for galvanized steel sheet.

EN 10346: European standard, covering the specifications and technical conditions of continuous hot-dip galvanized steel sheet.

JIS G3302: Japanese standard, which specifies the specifications and performance of hot-dip galvanized steel sheet.

GB/T 2518: Chinese national standard, which specifies the technical requirements for continuous hot-dip galvanized steel sheet and steel strip.

According to the different corrugated shapes and uses, galvanized corrugated steel sheets can be divided into:

Classification by corrugated shape

Corrugated corrugated sheet: the surface is wavy.

Trapezoidal corrugated sheet: the surface is trapezoidal and wavy.

V-shaped corrugated sheet: the surface is V-shaped and wavy.

Classification by coating

Single-sided galvanized corrugated sheet: only one side is galvanized.

Double-sided galvanized corrugated sheet: both sides are galvanized.

Galvanized corrugated steel sheets are widely used in construction and industrial fields, mainly including:

Building roofs and walls: used for roofs and walls of industrial plants, warehouses, farmhouses, shops, etc.

Fences and enclosures: used for construction site enclosures, temporary fences, guardrails, etc.

Indoor decoration: used for ceilings, interior wall decoration, etc.

Other uses: such as cooling tower shells, interior decoration of vehicles and ships, etc.

Galvanized corrugated steel sheet is an important construction and industrial material with good corrosion resistance and mechanical strength. Its production process includes pickling, cold rolling or hot rolling, galvanizing, forming and shearing. According to different application requirements, galvanized corrugated steel sheets of different materials and steel grades can be selected to ensure their excellent performance in various environments.