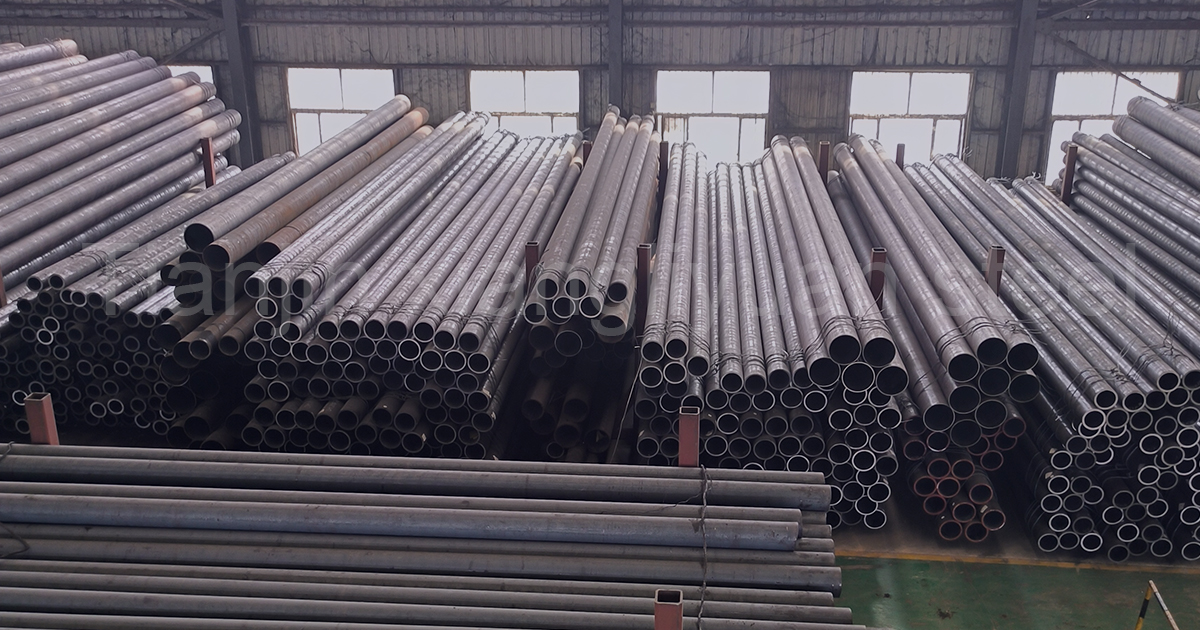

Welcome to Tianjin Xiangliyuan Steel, your trusted partner and a leading manufacturer in the steel industry. This guide provides a detailed overview of Electric Resistance Welded (ERW) Square and Rectangular Hollow Sections (SHS & RHS) tube, covering the most commonly requested materials, specifications, surface treatments, and applications by our global clientele. Our commitment is to offer not only superior quality products but also an extensive inventory and efficient service, ensuring your projects proceed smoothly and on schedule.

1. Introduction to ERW Square & Rectangular Tubes

ERW tubes are manufactured by cold-forming coiled steel sheet into a cylindrical shape and then welding the seam using high-frequency electrical current. This seam is subsequently processed to create a strong, uniform weld. These round tubes are then precisely formed into square or rectangular cross-sections through a series of sizing stands. The ERW process results in tubes with excellent dimensional accuracy, high strength-to-weight ratios, and smooth surfaces, making them a preferred choice for structural and mechanical applications worldwide.

2. Common Materials & Standards

The material grade is fundamental to the tube’s performance. We stock and produce ERW SHS/RHS in the following internationally recognized grades, catering to diverse regional and application-specific requirements:

ASTM A500 Grade B & C (USA Standard): This is arguably the most requested specification for structural tubing globally.

A500 Gr B: The standard grade for cold-formed welded carbon steel structural tubing. It offers a good balance of strength (minimum yield strength 50 ksi / 345 MPa) and weldability.

A500 Gr C: Provides higher strength (minimum yield strength 55 ksi / 380 MPa) for more demanding structural applications.

EN 10219 S235JR, S275JR, S355JR/J0/J2 (European Standard): These are the most common grades for cold-formed structural hollow sections in Europe and many other regions.

S235JR: Minimum yield strength of 235 MPa. Good for general structural purposes.

S275JR: Minimum yield strength of 275 MPa. Offers improved strength.

S355JR/J0/J2: Minimum yield strength of 355 MPa. The most popular high-strength grade for major construction and industrial projects. The suffixes (JR, J0, J2) indicate impact toughness at different temperatures.

JIS G 3444 STKR400 (Japanese Standard): Widely used in Asia and for specific export projects. STKR400 has a minimum yield strength of 235 MPa.

GB/T 6728 Q235B, Q355B (Chinese Standard): As a premier Chinese manufacturer, we fully comply with the high-quality requirements of the national standard.

Q235B: Comparable to S235JR, with a yield strength of ≥235 MPa.

Q355B: Comparable to S355JR, with a yield strength of ≥355 MPa, and is our most stocked high-strength grade.

We ensure all materials are sourced from reputable mills and come with complete Mill Test Certificates (MTCs) to guarantee chemical composition and mechanical properties.

3. Extensive Range of Sizes, Dimensions & Wall Thicknesses

At Tianjin Xiangliyuan Steel, we pride ourselves on our comprehensive inventory. We understand that project timelines hinge on material availability. Therefore, we stock a vast array of the most commonly purchased sizes, ensuring we can meet your needs promptly.

For Square Hollow Sections (SHS):

Common Sizes (mm): 20×20, 25×25, 30×30, 40×40, 50×50, 60×60, 75×75, 80×80, 100×100, 120×120, 150×150, 200×200, 250×250, 300×300, 400×400.

Standard Wall Thickness (mm): Ranging from 1.2mm, 1.5mm, 1.8mm, 2.0mm, 2.5mm, 3.0mm, 4.0mm, 5.0mm, 6.0mm, 8.0mm, 10.0mm, up to 12.0mm and 16.0mm for larger sizes.

For Rectangular Hollow Sections (RHS):

Common Sizes (mm): 20×10, 30×15, 40×20, 50×25, 60×30, 80×40, 100×50, 120×60, 150×100, 200×100, 250×150, 300×200, 400×200, 450×250.

Standard Wall Thickness (mm): Similar range as SHS, from 1.2mm to 16.0mm, selected based on dimension ratios.

Our Stock Advantage: For the standard sizes and thickness combinations listed above, which form the core of global demand, we maintain significant stock levels. This allows us to offer a remarkable lead time of just 5 to 7 days for processing and shipment for in-stock items. For non-standard or highly customized specifications, our modern production lines ensure competitive lead times, which we will confirm on a case-by-case basis.

4. Available Surface Treatments & Finishes

To enhance durability, aesthetics, and suitability for various environments, we offer multiple surface treatment options:

Bare / Black (As-welded): The standard finish with the mill scale, suitable for applications where the steel will be subsequently fabricated, painted, or galvanized on-site.

Hot-Dip Galvanized (HDG): The tube is immersed in a bath of molten zinc, providing a thick, durable coating that offers superior corrosion resistance for outdoor, industrial, or marine environments. This is one of our most requested finishes.

Pre-Galvanized: The steel coil is galvanized before the tube forming process. It offers a smooth, consistent zinc coating but is generally thinner than HDG, suitable for indoor or mild environments.

Powder Coating: A dry powder (polymer resin) is electrostatically applied and then cured under heat to form a hard, decorative, and protective finish available in any RAL color. Ideal for architectural and aesthetic applications.

Painted: Primed and painted with standard or specified industrial paints for corrosion protection.

Epoxy Coated / FBE: Fusion-Bonded Epoxy coating provides excellent chemical resistance and is often used in specific industrial settings.

5. Key Applications Across Industries

ERW SHS and RHS are versatile and used in countless sectors:

Construction & Building Structures: Primary and secondary framing, roof trusses, column supports, mezzanine floors, and architectural features. Their clean lines and high strength are ideal for modern construction.

Structural & Engineering Projects: Bridges, warehouses, stadiums, exhibition halls, and transmission towers.

Machinery & Equipment Manufacturing: As frames, bases, guards, and supports for agricultural machinery, conveyor systems, printing machines, and automation equipment.

Storage & Material Handling: Racking systems, pallet racks, shelves, and trolley frames.

Agricultural & Greenhouse Framing: For barns, greenhouses, and livestock equipment due to their strength and ease of assembly.

Automotive & Transportation: Trailer chassis, body frames, and components in commercial vehicles.

Furniture & Interior Design: For modern, industrial-style furniture, partitions, and decorative structures.

Why Choose Tianjin Xiangliyuan Steel?

Unmatched Product Range: Our extensive stock covers the vast majority of global standard specifications, meaning we likely have what you need, ready to go.

Speed to Market: Our strategic inventory management enables fast-track 5-7 day dispatch for standard items, drastically reducing your project lead times.

Quality Assurance: We adhere to strict international standards (ASTM, EN, JIS, GB) and implement rigorous in-house quality control at every production stage.

Technical Expertise: Our sales and engineering team possesses deep product knowledge and can provide professional support for material selection and specification.

Global Logistics Support: We have extensive experience in handling export documentation, packaging, and shipping to destinations worldwide, ensuring your order arrives safely and on time.

Partner with Us for Your Next Project

Whether you are a distributor, fabricator, or an end-user in the construction, engineering, or manufacturing sector, Tianjin Xiangliyuan Steel is equipped to be your reliable supplier of high-quality ERW square and rectangular tubes.

Contact us today with your specifications, and experience the combination of quality, variety, and speed that sets us apart.

Company: Tianjin Xiangliyuan Steel

Email: infosteel@xlygt.com

Let’s build the future, together.