Steel pipes are the unsung heroes of modern infrastructure and industry. As a fundamental component in construction, energy, transportation, and manufacturing, they provide the essential conduits for fluids, gases, and structural support that keep our world functioning. At Tianjin Xiangliyuan Steel, we have dedicated ourselves to mastering the art and science of steel pipe production, delivering superior quality products that meet the highest global standards.

Understanding Steel Pipes: Types and Manufacturing Processes

Steel pipes are primarily categorized by their production method, which defines their characteristics and optimal applications.

Seamless Steel Pipes are manufactured by piercing a solid billet of steel to create a hollow tube without any seams or welds. This process, which includes methods like hot rolling, extrusion, or drilling, results in pipes with exceptional strength and uniformity. Seamless pipes are ideal for high-pressure applications in the oil and gas industry, power generation, and high-stress mechanical systems. Their lack of a weld line eliminates a potential point of failure, making them the preferred choice for critical, demanding environments.

Welded Steel Pipes are produced by rolling steel plate or strip into a cylindrical shape and then welding the seam longitudinally. Advanced welding techniques like Submerged Arc Welding (SAW), High-Frequency Induction (HFI) welding, and Laser Welding ensure robust, reliable joints. Welded pipes are highly efficient to produce in large volumes and are available in larger diameters. They are the backbone of plumbing, water transmission, structural applications (like scaffolding), and lower-pressure pipeline systems.

Key specifications that define pipe performance include:

Grade: The chemical composition and mechanical properties (e.g., API 5L Grade B, X42-X80; ASTM A106 Grade B; ASTM A53).

Schedule: Wall thickness designation (Schedule 40, 80, etc.), which determines pressure capacity.

Finish: Black (as rolled), galvanized (zinc-coated for corrosion resistance), or coated (with epoxy, PE, or 3LPE for protection).

Dominant Materials: Carbon Steel and Stainless Steel Pipes

Carbon Steel Pipes, including ASTM A106 and ASTM A53 grades, are the most widely used due to their excellent strength, durability, and cost-effectiveness. They are the standard for structural frameworks, industrial plumbing, and conveying water, oil, and gas. We meticulously control carbon content to balance hardness with weldability and formability.

Stainless Steel Pipes, particularly ASTM A312 grades like 304 and 316, offer unparalleled corrosion and heat resistance. Their chromium (and often nickel) content forms a passive oxide layer that protects against rust. This makes them essential for:

Food and beverage processing equipment

Pharmaceutical and chemical plants

Architectural and marine applications

High-purity semiconductor manufacturing

Critical Applications Driving Global Demand

The versatility of steel pipes ensures their presence across every major sector:

Oil and Gas Industry: This sector relies heavily on both seamless and welded line pipe manufactured to API 5L specifications. From high-pressure transmission pipelines and drill pipes to casing and tubing for well construction, steel pipes must withstand extreme pressures, corrosive elements, and harsh environments.

Construction and Infrastructure: Steel pipes form the skeletons of skyscrapers, bridges, and stadiums as structural columns and piles. They are also used for water supply, drainage, fire sprinkler systems, and scaffolding. The durability and load-bearing capacity of steel are unmatched.

Mechanical and Engineering Applications: In manufacturing plants, steel pipes are used for transporting hydraulic fluids, steam, and process chemicals. Precision tubes are critical in automotive manufacturing, machinery, and bearing systems.

Energy and Power Generation: Boiler tubes, superheater tubes, and condenser tubes in thermal power plants are often made from specialized alloy steels to withstand high temperatures and pressures. The renewable energy sector, including solar thermal and geothermal plants, also utilizes specialized piping systems.

Why Quality and Standards Are Non-Negotiable

At Tianjin Xiangliyuan Steel, we understand that a pipe failure can have catastrophic consequences. Therefore, our commitment to quality is embedded in every step of our operation. We adhere to stringent international standards such as API (American Petroleum Institute), ASTM (American Society for Testing and Materials), ASME (American Society of Mechanical Engineers), EN (European Norms), and ISO (International Organization for Standardization).

Our integrated quality control process includes:

Material Verification: Incoming steel coil and billet inspection.

In-Process Testing: Ultrasonic testing (UT), Eddy Current testing (ECT), and Hydrostatic pressure testing ensure weld integrity and leak-proof performance.

Dimensional Checks: Laser gauging for precise OD, wall thickness, and straightness.

Final Certification: Every batch is supplied with a Mill Test Certificate (MTC) detailing its chemical and physical properties, traceable to its production heat number.

Tianjin Xiangliyuan Steel: Your Trusted Partner in Steel Solutions

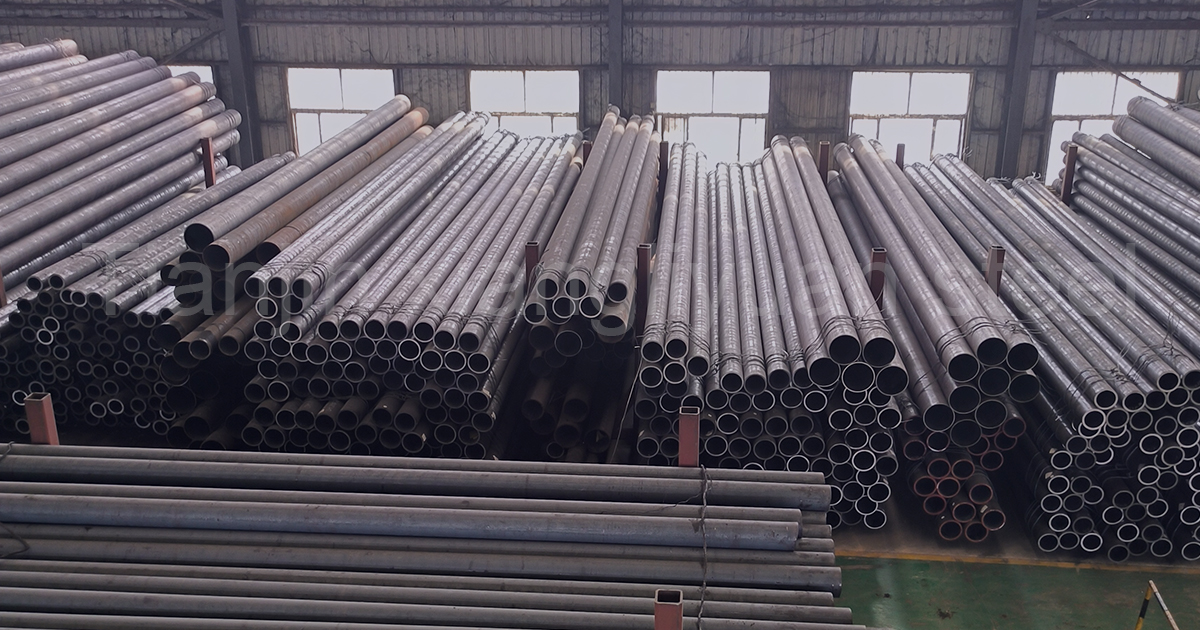

Founded on the principles of integrity, innovation, and customer focus, Tianjin Xiangliyuan Steel has grown into a respected manufacturer and exporter of a comprehensive range of steel pipes. Our product portfolio includes:

Seamless Steel Pipes (Hot Finished & Cold Drawn)

ERW (Electric Resistance Welded) and LSAW (Longitudinally Submerged Arc Welded) Pipes

Carbon Steel Pipes & Tubes for structural and fluid conveyance

Stainless Steel Pipes for corrosive and high-purity applications

Galvanized Steel Pipes for extended outdoor and plumbing use

Specialty Pipes to customer specifications and drawings

Our state-of-the-art manufacturing facilities are equipped with advanced technology, allowing us to produce pipes from 1/2″ to 48″ in diameter, with stringent control over tolerances and finish. We serve a global clientele across six continents, building long-term partnerships by delivering on-time, reliable, and cost-effective solutions.

Whether you are an engineering firm specifying materials for a mega-project, a distributor serving local markets, or a manufacturer requiring precision components, we have the expertise and capacity to meet your needs.

For inquiries, quotations, or technical specifications, please do not hesitate to contact our expert team. We are here to provide tailored solutions for your specific project requirements.

Email: infosteel@xlygt.com

Tianjin Xiangliyuan Steel – Delivering Strength, Precision, and Reliability in Every Pipe.