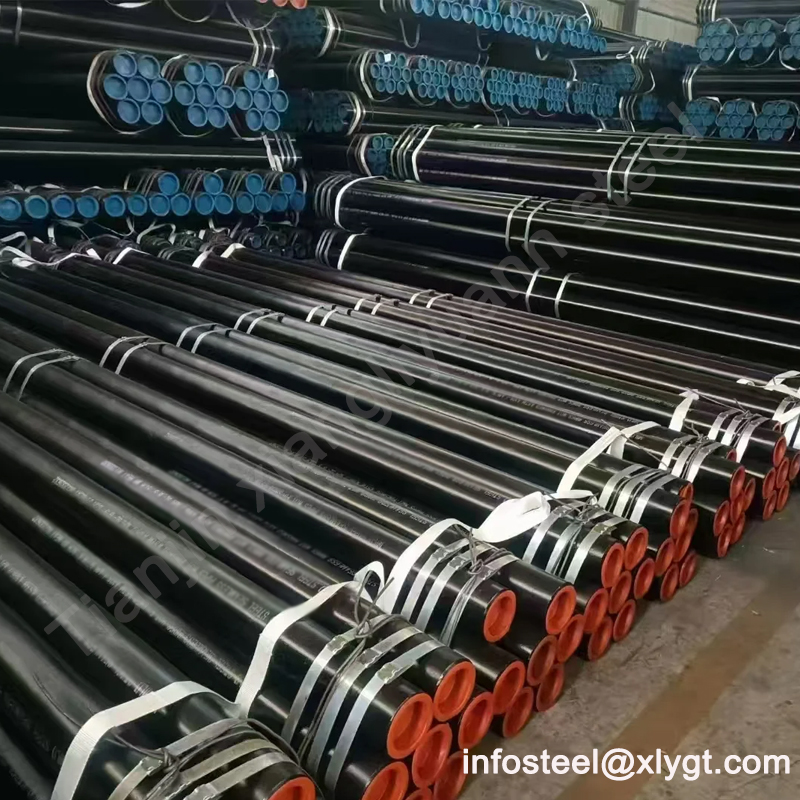

In an interconnected world, the safe and efficient transportation of oil and natural gas is fundamental to global energy security and economic stability. At the very heart of this vast, often invisible network lie critical components: pipeline steel tubes. These are not merely pieces of metal; they are engineering marvels designed to withstand extreme pressures, corrosive environments, and decades of service across continents and ocean floors. As a leading force in China’s manufacturing sector, Tianjin Xiangliyuan Steel is dedicated to producing high-performance pipeline tubes that form the reliable backbone of the world’s energy infrastructure.

Understanding Oil & Gas Pipeline Steel Tubes

Pipeline tubes, or line pipe, are specifically manufactured to transport hydrocarbons over long distances from extraction points (oil & gas fields, shale formations) to refineries, processing plants, and ultimately to distribution centers and consumers. They are categorized mainly by their manufacturing process:

Seamless Steel Pipe (SMLS): Created by piercing a solid billet of steel to form a hollow shell without any seam. This process offers superior uniformity in wall thickness and exceptional strength, making it ideal for high-pressure applications, offshore projects, and challenging environments.

Longitudinally Submerged Arc Welded (LSAW) Pipe: Manufactured by bending and forming steel plates, then welding the longitudinal seam using the Submerged Arc Welding (SAW) process. LSAW pipes are known for their large diameters (typically from 16 inches upwards), high pressure ratings, and are the primary choice for cross-country and subsea transmission mains.

Spiral Submerged Arc Welded (SSAW/HSAW) Pipe: Produced by helically coiling a steel strip and welding the seam spirally. This method allows for great flexibility in producing pipes with various diameters from the same strip width and offers good dimensional stability.

Key Technical Requirements and Global Standards

The operational demands on pipeline tubes are immense, governed by rigorous international and regional standards to ensure safety, durability, and performance.

Primary Material Standards: The most critical and widely recognized standard is API 5L (American Petroleum Institute). This specification covers seamless and welded steel line pipe and defines grades such as PSL1 and the more stringent PSL2, with grades ranging from B, X42, X52, X56, X60, X65, X70, up to X80 and beyond for high-strength applications. Other vital standards include ISO 3183, DNVGL-ST-F101 (for offshore pipelines), and GB/T 9711 (Chinese national standard equivalent).

Crucial Performance Characteristics:

High Strength & Toughness: Tubes must possess high yield strength (e.g., Grade X65, X70) and excellent impact toughness, especially at low temperatures (tested via Charpy V-Notch tests), to prevent brittle fracture and ensure integrity in arctic climates or deep water.

Superior Weldability: Consistent chemical composition (controlled Carbon Equivalent – CE, Pcm) is essential for flawless field welding during pipeline construction.

Exceptional Corrosion Resistance: Pipes are often coated externally (FBE, 3LPE) and sometimes internally to combat soil corrosion, moisture, and transported media. For highly corrosive environments, Corrosion Resistant Alloy (CRA) lined pipes or Stainless Steel options are employed.

Dimensional Accuracy & Consistency: Precise outer diameter (OD), wall thickness (WT), and ovality are mandatory for the efficiency of coating, welding, and laying operations.

Applications Across the Energy Spectrum

Pipeline tubes from Tianjin Xiangliyuan Steel are engineered for diverse and demanding applications:

Onshore Transmission Pipelines: The vast networks crossing continents, requiring high-strength LSAW and SSAW pipes in grades X65-X80 for main lines, and seamless tubes for gathering lines.

Offshore & Subsea Pipelines: Subject to tremendous water pressure, currents, and corrosive seawater. These projects demand heavy-wall, high-grade seamless or LSAW pipes with superior toughness and often require CRA cladding.

Gathering Lines & Casing: Transporting raw resources from wellheads to processing facilities, often requiring robust seamless pipes.

City Gate & Distribution Networks: Connecting major transmission lines to local utilities, utilizing a range of welded and seamless pipes.

Special Services: Including pipes for sour service (resisting Hydrogen Induced Cracking – HIC and Sulfide Stress Cracking – SSC), low-temperature service, and high-pressure CO2 transport.

Why Choose Tianjin Xiangliyuan Steel as Your Pipeline Partner?

Tianjin Xiangliyuan Steel stands as a premier Chinese manufacturer committed to excellence in every meter of pipe we produce. Our commitment integrates advanced technology, stringent quality control, and a customer-centric approach.

Comprehensive Product Portfolio: We supply a full range of pipes including API 5L PSL1/PSL2 Line Pipe, Seamless Steel Pipe for critical sections, and high-quality LSAW and SSAW pipes for large-diameter projects, all customizable to specific project needs (OD, WT, grade, length).

Uncompromising Quality Assurance: Our manufacturing process is underpinned by a full Quality Management System. We employ state-of-the-art non-destructive testing (NDT) methods like Ultrasonic Testing (UT), Radiographic Testing (RT), and Hydrostatic Testing to ensure every pipe meets or exceeds the required standards for dimensional accuracy, mechanical properties, and defect-free construction.

Advanced Manufacturing & Technical Expertise: Our facilities house modern production lines capable of handling high-strength, low-alloy (HSLA) steels. Our metallurgical experts work closely with clients to develop solutions for challenging specifications, including HIC Resistant steels and extreme low-temperature grades.

Global Logistics & Project Support: We understand the scale of pipeline projects. Our team ensures timely delivery, complete with all necessary mill test certificates (MTC), traceability documentation, and packaging suitable for long-distance sea freight and harsh site conditions.

Building the Future of Energy Transport Together

The global energy landscape is evolving, with new challenges in exploring remote reserves, deep-water fields, and transporting alternative energy carriers. Tianjin Xiangliyuan Steel is at the forefront of this evolution, investing in R&D for next-generation pipeline steels that offer even greater strength, resilience, and environmental sustainability.

Whether you are an EPC contractor, an oil & gas major, or a distributor involved in a landmark cross-country pipeline, a subsea tie-back, or a local distribution network, you need a supplier you can rely on for quality, consistency, and technical support.

Let us be your trusted partner in building safe and efficient energy highways.

Contact us today to discuss your project requirements, request a quotation, or obtain detailed technical data sheets.

Company: Tianjin Xiangliyuan Steel

Website: https://www.xlysteel.com/

Email: infosteel@xlygt.com