Plastic Coated Steel Pipes: The Ultimate Guide for Corrosion Resistance by Tianjin Xiangliyuan Steel

In the world of industrial and municipal infrastructure, the longevity and reliability of piping systems are paramount. Corrosion remains the single greatest threat to pipeline integrity, leading to costly maintenance, operational downtime, and environmental hazards. For international buyers seeking a robust and cost-effective solution, Plastic Coated Steel Pipes (also known as Plastic Lined Steel Pipes or Anti-Corrosion Steel Pipes) stand out as the premier choice. This comprehensive guide, presented by Tianjin Xiangliyuan Steel, a trusted manufacturer in the field, will delve into the critical aspects that matter most in your procurement decision.

The Synergy of Strength and Protection

A Plastic Coated Steel Pipe ingeniously combines the superior mechanical strength of steel with the exceptional chemical resistance of a plastic layer. The result is a pipe that can withstand high pressures, external impacts, and aggressive environments, both underground and aboveground. At Tianjin Xiangliyuan Steel, we specialize in producing these high-performance pipes to meet the rigorous demands of global projects, ensuring decades of trouble-free service.

1. Material Composition: The Foundation of Quality

The quality of a coated pipe begins with its core components:

Base Pipe: We use high-quality carbon steel as the substrate. The steel pipe itself must conform to standards like API 5L (for line pipe) or ASTM A53/A106 (for structural and pressure applications). The surface is meticulously cleaned through abrasive blasting (SA 2.5 grade) to achieve a near-white metal finish, which is crucial for optimal coating adhesion.

Coating Material: The type of plastic coating determines the pipe’s resistance profile. The two most common and effective types are:

Epoxy Powder Coating (FBE): This thermosetting powder is applied electrostatically and then cured under heat. It creates a hard, dense, and adherent layer with excellent resistance to a wide range of chemicals and solvents. Its thin profile makes it ideal for projects where dimensional tolerances are critical.

Polyethylene Coating (PE) / Polypropylene Coating (PP): These thermoplastic coatings are applied via extrusion, resulting in a thick, tough, and flexible layer. PE coating offers outstanding resistance to moisture, abrasion, and impact, making it perfect for harsh underground conditions. PP coating provides superior resistance to higher temperatures and a broader spectrum of chemicals.

2. Adherence to International Standards: Your Assurance of Quality

For international clients, compliance with recognized standards is non-negotiable. It is a guarantee of performance, safety, and interoperability. Tianjin Xiangliyuan Steel’s production processes and final products are strictly in accordance with the following key international standards:

AWWA C210: This is the leading standard for liquid epoxy coating systems for the interior and exterior of steel water pipelines. It is a benchmark for municipal water supply projects.

AWWA C213: This standard covers both fusion-bonded epoxy (FBE) and polyethylene (PE) coatings for the interior and exterior of steel water pipelines.

ISO 21809-1: A comprehensive international standard for external coatings for buried and submerged pipelines used in pipeline transportation systems, covering FBE, 2-layer PE, and 3-layer Polypropylene (PP) coatings.

DIN 30670: A German standard specifying polyethylene and polypropylene coatings for steel pipes and fittings, widely respected and referenced across Europe and the Middle East.

ASTM A755/A755M: Standard specification for steel sheet, metallic-coated by the hot-dip process and prepainted by the coil-coating process for exterior exposed building products.

Our commitment to these standards ensures that every pipe we ship is fit for purpose and built to last.

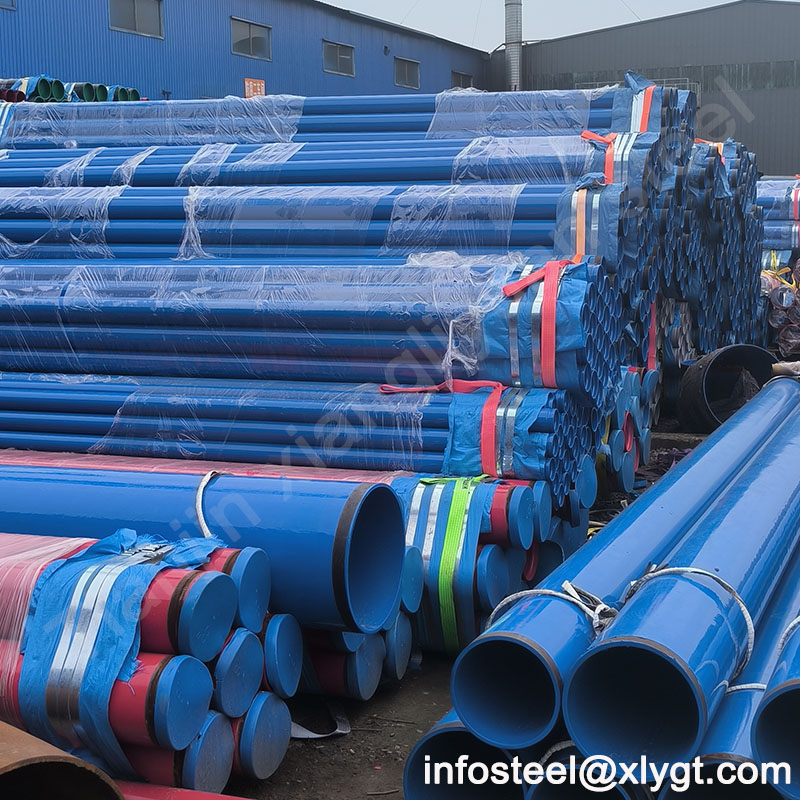

3. Coating Colors and Their Applications: More Than Just Aesthetics

The color of the plastic coating is not merely for identification; it often corresponds to specific applications and regional standards, a key point for project planners.

Blue: Universally recognized for potable water systems. Blue-coated pipes from Tianjin Xiangliyuan Steel are certified to be safe for transporting drinking water, with coatings that do not leach harmful substances.

Black: The most common color for general-purpose and industrial applications, including oil and gas pipelines, firefighting systems, and piling. The carbon black additive in black polyethylene provides enhanced UV resistance.

Green: Typically used for sewage and wastewater systems. The green color provides a clear visual distinction from water lines, preventing cross-connection during installation and maintenance.

Yellow / Orange: Often designated for gas pipelines or hazardous material conveyance, ensuring high visibility for safety and identification.

Red: Primarily used for fire sprinkler systems and firefighting water mains, allowing for quick identification in emergencies.

Custom Colors: We understand that some projects may require specific color codes. Tianjin Xiangliyuan Steel offers custom color coating to meet unique client specifications.

4. Key Characteristics and Advantages: Why Choose Plastic Coated Pipes?

When you source from Tianjin Xiangliyuan Steel, you invest in a product with unparalleled advantages:

Superior Corrosion Resistance: The primary benefit. The plastic layer acts as a permanent barrier, isolating the steel from corrosive elements like soil, moisture, chemicals, and electrolytes, effectively preventing rust and pitting.

Smooth Hydraulic Performance: The interior coating is extremely smooth, significantly reducing the friction coefficient. This minimizes pressure loss, increases flow efficiency, and reduces pumping costs. It also prevents scale and biofilm buildup.

Excellent Abrasion and Impact Resistance: Especially with thick PE/PP coatings, the pipes are highly durable against soil stress, rocks, and handling during installation.

Long Service Life: Properly manufactured and installed, these pipes can have a service life exceeding 50 years, drastically reducing the total cost of ownership compared to alternative materials.

Ease of Installation and Maintenance: The coating is lightweight and flexible. Many of our coated pipes can be connected using standard methods like flanges, grooved couplings, or welding (with field joint protection), simplifying the installation process. Their durability also means minimal maintenance is required.

5. What International Buyers Should Prioritize: A Checklist from Tianjin Xiangliyuan Steel

As an experienced supplier to the global market, we advise our clients to focus on these critical points:

Project-Specific Coating Selection: Don’t choose a coating in isolation. Define the fluid being transported, operating temperature and pressure, and the installation environment (buried, aerial, submerged). We provide expert consultation to match the right coating (FBE, PE, PP) to your project’s needs.

Third-Party Certification: Insist on mill test certificates (MTCs) and, for critical projects, independent third-party inspection reports. This verifies compliance with the claimed standards.

Coating Thickness and Adhesion: Ensure the supplier has strict quality control for coating thickness (measured electronically) and adhesion (tested via peel-off or cross-cut tests). Poor adhesion leads to coating failure.

End-User Standards Compliance: Confirm that the pipes meet the specific national or corporate standards required by the end-client (e.g., a water authority may mandate AWWA C210).

Supplier’s Reputation and Track Record: Partner with a manufacturer like Tianjin Xiangliyuan Steel with a proven history of supplying quality products to international markets. Look for experience in projects similar to yours.

Packaging for Export: The coating must be protected during long-distance shipping. We use protective end caps and tailored packaging (e.g., wooden crates or steel frames) to prevent damage.

Partner with a Reliable Supplier

Selecting the right Plastic Coated Steel Pipe is a strategic decision that impacts the safety, efficiency, and cost-effectiveness of your project for decades. It requires a supplier that not only understands manufacturing but also comprehends the nuanced requirements of international standards and applications.

At Tianjin Xiangliyuan Steel, we combine advanced manufacturing technology with rigorous quality control and a deep understanding of our clients’ needs. We are more than just a manufacturer; we are your partner in ensuring the success and durability of your infrastructure.

Contact Tianjin Xiangliyuan Steel today to discuss your project requirements and receive a detailed quotation for high-quality, standards-compliant Plastic Coated Steel Pipes.