Channel steel is a common building steel material with a “U”-shaped cross-section, usually used for structural support and frame construction. The cross-sectional shape of channel steel determines its mechanical properties and is widely used in construction, machinery manufacturing, vehicle manufacturing, bridge construction and other fields.

Channel steel can be divided into the following categories according to different classification standards:

1. Classification by shape

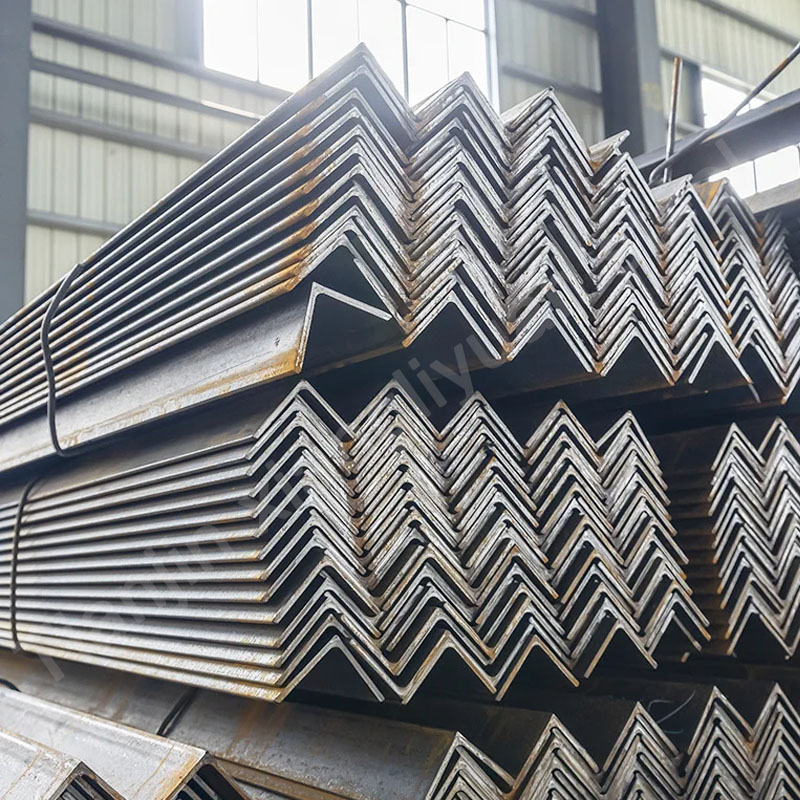

Ordinary channel steel: also known as hot-rolled ordinary channel steel, with an ordinary “U”-shaped cross-section, relatively uniform flange width and web thickness, widely used in construction and industrial structures.

Light channel steel: Compared with ordinary channel steel, light channel steel has the same cross-sectional height, but is lighter and thinner in wall, suitable for light structures.

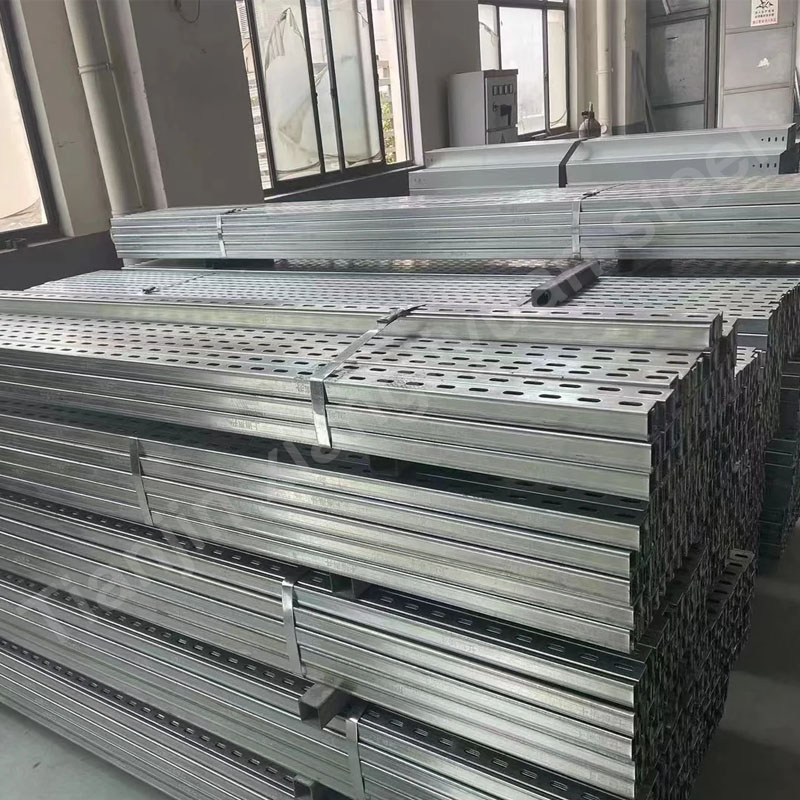

Cold-bent channel steel: It is formed by cold bending of steel plates or steel strips, with thinner wall thickness and various cross-sectional shapes, and is commonly used in light steel structures, carriages and brackets, etc.

2. Classification by flange shape

Equilateral channel steel: that is, ordinary channel steel, with equal flange width and symmetrical shape.

Unequal channel steel: The flange width or thickness is unequal, suitable for special structures.

3. Classification by production process

Hot-rolled channel steel: produced by hot rolling process, mainly used in large structural projects.

Cold-bent channel steel: produced by cold bending process, often used for light structures and decorative purposes.

4. Classification by use

Structural channel steel: used for building structures, bridges, vehicles, machinery, etc.

Decorative channel steel: used in decorative projects, such as door and window frames, exterior wall decoration, etc.

Special purpose channel steel: such as combined channel steel, suitable for specific purposes and environmental needs.

5. Classification by size

Ordinary channel steel: commonly used height is 5-40cm, suitable for general structures and supports.

Large channel steel: height above 40cm, mainly used for bridges and heavy equipment supports.

6. Classification by steel material

Carbon steel channel steel: made of ordinary carbon steel such as Q235 and Q345.

Alloy steel channel steel: made of high-strength alloy steel such as Q390 and Q420, suitable for structures with high load requirements.

Through these classifications, the application of channel steel can be more accurately matched to different engineering needs.

Channel steel is usually made of steel of different grades to meet different load-bearing requirements. Common steel grades include:

Q235: commonly used in general buildings and light structures.

Q345: higher strength, suitable for structures with higher load-bearing requirements.

Q390/Q420/Q460: used in engineering and buildings with higher strength requirements.

The production and application standards of channel steel vary from country to country. The following are common standards:

Chinese standard:

GB/T 706-2008 (hot-rolled steel)

GB/T 6723-2008 (cold-bent steel)

Japanese standard:

JIS G3192 (hot-rolled steel)

European standard:

EN 10025 (hot-rolled steel)

American standard:

ASTM A36/A36M (structural steel)

Channel steel is mainly used in the following areas:

1. Building structure

Channel steel is commonly used in steel structure frame beams, columns, trusses, steel structure bridges and other parts in construction projects. They provide support and bending resistance and are suitable for structures such as high-rise buildings, factories, warehouses, etc.

2. Machinery Manufacturing

In the field of machinery manufacturing, channel steel is often used to manufacture the chassis, support frame, frame structure, etc. of equipment. Because channel steel has good mechanical properties and rigidity, it is suitable for mechanical structural parts that need to bear weight.

3. Vehicle Manufacturing

Channel steel is widely used in the chassis, beams and other load-bearing parts of trucks and train carriages. Its strength and durability make it an important structural material in transportation tools.

4. Bridge Construction

In bridge structures, channel steel is usually used as the main beam, cross beam and supporting member of the bridge. It can withstand large loads and ensure the stability and safety of the bridge.

5. Brackets and Frames

Channel steel is also widely used to manufacture various brackets and frame structures, such as telephone poles, billboard brackets, conveyor belt frames, equipment platforms, etc.

6. Industrial Buildings and Equipment

In industrial buildings such as factories and workshops, channel steel is often used to make various equipment brackets, platform structures, stair handrails, etc. to ensure the stability and safety of the equipment.

7. Shipbuilding and marine engineering

Channel steel is also used for structural components of shipbuilding and marine engineering, such as hull frames, deck structures, etc., with corrosion resistance and load-bearing capacity.

8. Other uses

Channel steel is also used to manufacture lighter structures such as shelves, support columns, and building formwork supports.

Channel steel is widely used in various structural support and load-bearing occasions due to its good bending resistance, superior cross-sectional performance and diverse specifications.