In the world of construction, the integrity of the entire structure often rests on components that go unnoticed. Among these, steel pipes play a pivotal role, serving as the arteries for fluids, the skeleton for frameworks, and the conduits for essential services. Selecting the right steel pipe is not merely a procurement decision; it is a foundational engineering choice that impacts safety, longevity, cost-efficiency, and project success. With a myriad of options available on the global market, making an informed decision can be daunting.

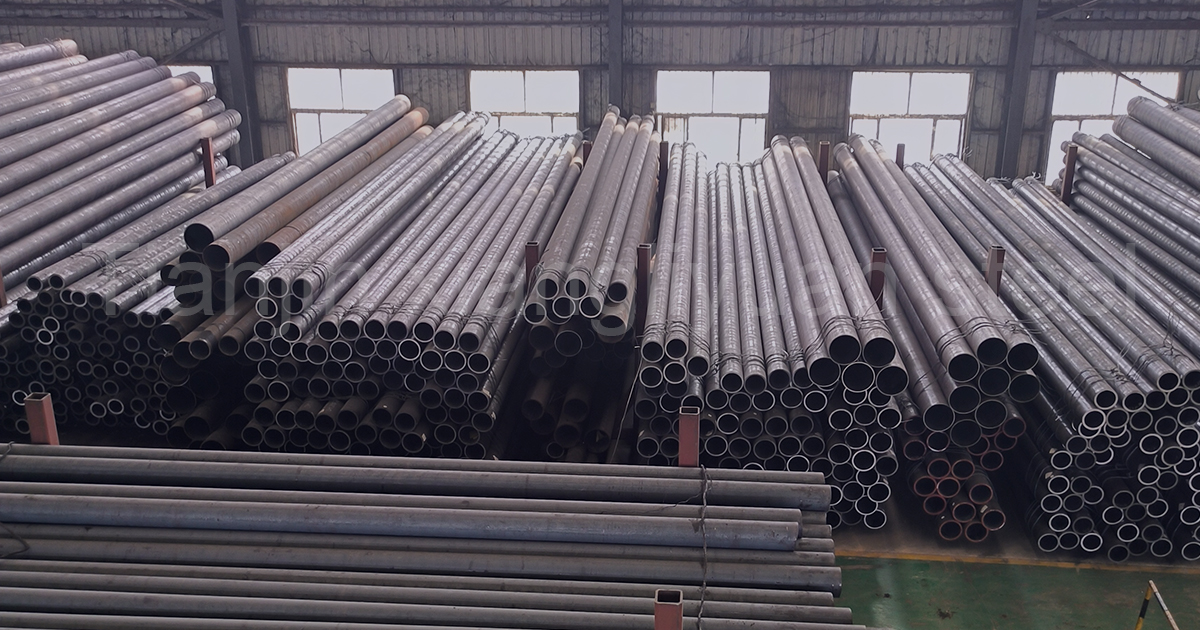

As a leading steel pipe manufacturer and supplier, Tianjin Xiangliyuan Steel has decades of experience supporting international construction projects. We understand that the optimal choice balances technical specifications, application demands, and budgetary constraints. This guide delves into the five most critical factors you must evaluate to ensure you select the perfect steel pipes for your construction project.

1. Material Grade and Type: The Foundation of Performance

The journey begins with the fundamental composition of the pipe. Not all steel is created equal, and the material grade directly dictates properties like strength, ductility, weldability, and corrosion resistance.

Carbon Steel vs. Alloy Steel: For most general structural steel pipe applications, carbon steel pipes (like those conforming to ASTM A53 or A106) offer an excellent balance of strength and affordability. However, for projects involving high pressure, extreme temperatures, or corrosive environments (common in oil and gas or chemical plants), alloy steel pipes or seamless steel pipes with specific chromium, molybdenum, or nickel content (e.g., ASTM A335 P11, P22) are indispensable.

The Seamless vs. Welded Debate: This is a crucial distinction. Seamless steel pipes are manufactured by piercing a solid billet, offering superior strength and uniformity, making them ideal for high-pressure applications. Welded steel pipes (ERW – Electric Resistance Welded, LSAW – Longitudinal Submerged Arc Welded, SSAW – Spiral Submerged Arc Welded) are formed from rolled steel plate and welded along the seam. They are cost-effective for larger diameters and are perfectly suited for structural applications, piling, and low-to-medium pressure conveyance. At Tianjin Xiangliyuan Steel, we produce a comprehensive range of both seamless and welded pipes, ensuring we can recommend the most suitable type for your specific stress and pressure requirements.

Key Search Terms Integration: When specifying material, engineers often search for “API 5L steel pipe” for line pipe applications, “ASTM A500 pipe” for structural tubing, or “black steel pipe” and “galvanized steel pipe” for specific finishes and corrosion protection.

2. Dimensional Specifications and Tolerances: Precision in Fit

A pipe must fit its purpose both functionally and physically. Incorrect dimensions can lead to installation failures, system inefficiencies, and significant cost overruns.

Nominal Pipe Size (NPS) and Schedule (SCH): The NPS (e.g., 2″, 6″, 12″) and Schedule number (e.g., SCH 40, SCH 80, STD, XS) define the outer diameter and wall thickness of the pipe. A higher schedule means a thicker wall, capable of handling higher internal pressures. It is vital to adhere to the wall thickness specifications outlined in your project’s P&IDs (Piping and Instrumentation Diagrams).

Outer Diameter (OD) and Inner Diameter (ID): Consistency in OD is critical for proper fitting and welding. Precision in ID is essential for maintaining the required flow rate in piping systems.

Length: Standard random lengths exist, but many projects require specific cut-to-length pipes to minimize waste and on-site fabrication time. A reliable supplier should offer flexible cutting options.

Why Tolerances Matter: International standards like ASTM, ASME, and EN define permissible dimensional tolerances. A manufacturer that consistently delivers pipes within these tight tolerances, like Tianjin Xiangliyuan Steel, ensures smoother, faster installation and reduces rework. Searching for “pipe dimensions chart”, “pipe schedule chart”, or “HSS pipe sizes” (for Hollow Structural Sections) is common during this specification phase.

3. Mechanical and Chemical Properties: Ensuring Structural Integrity

The paper specification must translate into real-world performance. The mechanical and chemical properties of the pipe are non-negotiable checkpoints.

Yield Strength and Tensile Strength: These values (measured in MPa or psi) indicate how much stress the pipe can withstand before permanent deformation (yield) and before breaking (tensile). For high-strength steel pipes used in skyscrapers or long-span bridges, these numbers are paramount.

Hardness, Elongation, and Impact Toughness: Depending on the environment, resistance to abrasion (hardness), ability to deform without cracking (elongation), and performance in cold temperatures (impact toughness measured by Charpy V-notch tests) may be critical.

Chemical Composition Analysis: The percentage of carbon, manganese, silicon, sulfur, phosphorus, and other elements is verified through mill test certificates (MTCs) or certified steel pipe reports. This “chemical fingerprint” guarantees the pipe meets the claimed grade standard (e.g., ASTM A106 Gr. B, API 5L Gr. B).

Quality Assurance: Reputable suppliers provide full traceability and necessary documentation. Inquiries for “MTC steel pipe”, “test certificate for pipes”, or “carbon steel pipe specifications” reflect this crucial due diligence step.

4. End-Use Application and Environmental Factors

The pipe does not exist in a vacuum. Its selection is wholly dependent on its final job and the conditions it will face.

Application-Specific Standards:

Structural Applications: Look for pipes complying with ASTM A500 (round, square, rectangular tubing) for buildings and frames.

Piling and Foundation: ASTM A252 pipe is specifically designed for structural support in foundations.

Fluid Transport: API 5L governs line pipe for oil, gas, and water transmission. ASTM A53 and A106 are common for process piping.

High-Temperature Service: Standards like ASTM A335 for alloy pipes are essential.

Corrosion: The Silent Threat: This is a major factor in pipe selection. Options include:

Galvanized Steel Pipes: Zinc-coated for basic corrosion protection.

Stainless Steel Pipes: For highly corrosive environments (food processing, chemical plants).

Coatings and Linings: Epoxy, FBE (Fusion Bonded Epoxy), or 3LPE coatings are applied to carbon steel pipes for underground or subsea pipelines.

Cathodic Protection: Often used in conjunction with coatings.

Geographical and Climate Considerations: Projects in coastal areas require higher corrosion resistance. Arctic projects need pipes with excellent low-temperature toughness. Searches like “corrosion resistant steel pipe”, “epoxy coated pipe”, or “pipe for offshore applications” are highly relevant here.

5. Supplier Reliability and Total Cost Considerations

The final factor moves beyond the product itself to the partnership that ensures its delivery.

Beyond Unit Price: The Total Cost of Ownership (TCO): The cheapest pipe per ton may become the most expensive. Consider:

Consistency & Quality: Poor quality leads to rejection, delays, and safety risks.

Technical Support: Can the supplier offer engineering support on pipe selection?

Logistics & Lead Time: Reliable on-time delivery prevents project stalls.

Certification & Compliance: A supplier with a robust Quality Management System (often ISO 9001 certified) provides peace of mind.

The Value of a Trusted Partner: A manufacturer like Tianjin Xiangliyuan Steel operates not just as a vendor but as a solutions provider. From the initial inquiry at infosteel@xlygt.com through to the provision of detailed quotations, technical data, and final shipment, a professional partner ensures a smooth procurement process. Look for a supplier with a proven track record in exporting to international markets, capable of handling the complexities of international trade and documentation.

Common Procurement Queries: Buyers often search for “steel pipe suppliers”, “steel pipe price list”, “steel pipe manufacturers in China”, “API 5L pipe distributor”, or “bulk steel pipe quotes”. A strong online presence with informative, professional content (like this article) is often the first step in building that trust.

An Informed Decision is a Sustainable Decision

Selecting the right steel pipe is a multi-variable equation where material type, dimensional accuracy, verified properties, application fit, and supplier reliability must all be solved for. Neglecting any one of these five key factors can compromise your project’s timeline, budget, and most importantly, its structural safety.

By partnering with an experienced and technically proficient manufacturer, you gain more than just a product; you gain expertise. At Tianjin Xiangliyuan Steel, we are committed to providing not only high-quality steel pipes that meet the strictest international standards but also the technical guidance to help you make the best choice.

Ready to Specify the Right Pipes for Your Project?

Our technical sales team is available to discuss your specific requirements for seamless, ERW, LSAW, or structural steel pipes. For a detailed quotation, project consultation, or to request mill test certificates and product brochures, please contact us at infosteel@xlygt.com. Let’s build a stronger future, together.