Carbon steel plates are fundamental materials in numerous industries, ranging from construction and shipbuilding to heavy machinery and energy infrastructure. As a leading supplier, we understand that selecting the right type of carbon steel plate is critical for the success, safety, and longevity of your project. This comprehensive guide will delve into the various classifications of carbon steel plates, providing you with the professional insights needed to make an informed decision.

Carbon steel, primarily an alloy of iron and carbon, is prized for its strength, durability, and cost-effectiveness. The classification of carbon steel plates is not based on a single criterion but rather on a combination of factors including carbon content, manufacturing process, microstructure, and deoxidation practice. Understanding these classifications is key to specifying the correct material for your application.

I. Classification by Carbon Content

This is the most common and fundamental way to categorize carbon steel. The amount of carbon present directly influences the steel’s hardness, strength, ductility, and weldability.

1. Low Carbon Steel / Mild Steel Plates

Carbon Content: Typically less than 0.25%.

Properties: This is the most widely used form of carbon steel. It offers excellent ductility and formability, making it easy to machine, weld, and fabricate. While it has lower strength and hardness compared to higher carbon grades, it provides good toughness and is relatively inexpensive.

Common Grades: ASTM A36, ASTM A283 Grade C, AISI 1018.

Applications: Structural frames, building frameworks, automobile chassis, ship hulls, and sheet metal components.

2. Medium Carbon Steel Plates

Carbon Content: Between 0.25% and 0.60%.

Properties: Medium carbon steel strikes a balance between ductility and strength. It can be heat-treated (through processes like quenching and tempering) to significantly enhance its mechanical properties, resulting in higher strength and hardness. However, its weldability is more challenging than mild steel, often requiring pre-heating and post-weld heat treatment to prevent cracking.

Common Grades: ASTM A516 Grade 70 (pressure vessel quality), AISI 1045.

Applications: Gears, shafts, railway tracks, crankshafts, and high-strength structural components.

3. High Carbon Steel Plates

Carbon Content: Between 0.60% and 1.0%.

Properties: This grade offers the highest level of hardness and strength among the plain carbon steels. It is, however, the least ductile and most brittle, making it difficult to weld and form. High carbon steel is almost always used in a heat-treated state to achieve desired properties.

Common Grades: AISI 1060, AISI 1095.

Applications: Cutting tools, blades, springs, high-strength wires, and wear-resistant parts like grader blades.

4. Very High Carbon Steel Plates

Carbon Content: Typically between 1.0% and 2.0%.

Properties: This specialized category offers extreme hardness but is very brittle and difficult to work with. It is not commonly used for structural plate applications but is reserved for specific, non-structural purposes requiring exceptional wear resistance.

Applications: Specialized cutting tools, punches, and dies.

II. Classification by Manufacturing Process

The method used to produce the steel plate imparts distinct characteristics, especially on its surface finish, dimensional tolerances, and internal grain structure.

1. Hot Rolled Steel (HR) Plates

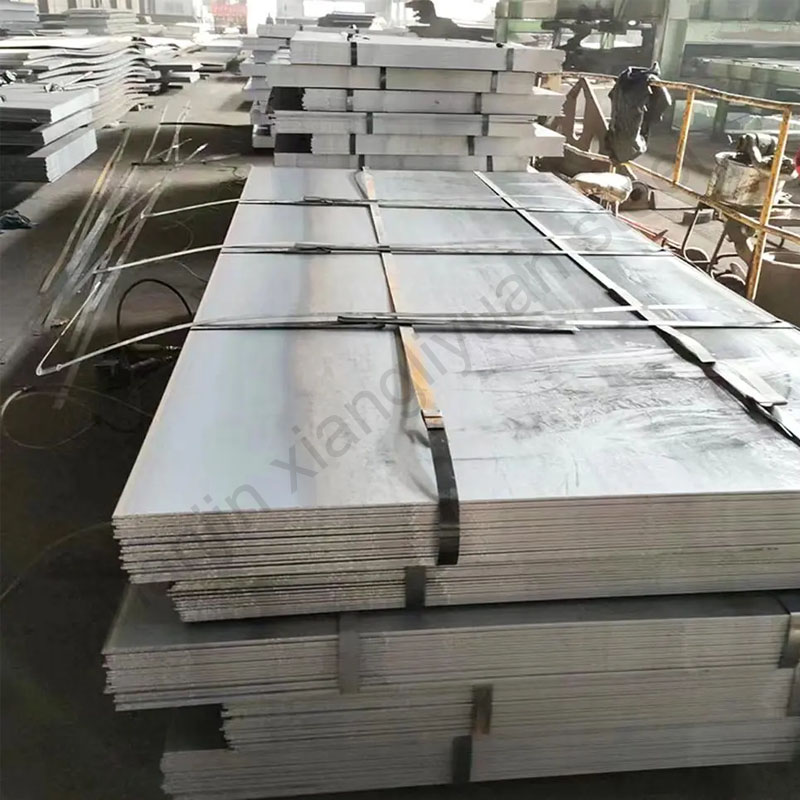

Hot rolling is a process where the steel slab is heated above its recrystallization temperature (over 1700°F) and passed through a series of rollers. This is the most common method for producing thicker carbon steel plates.

Properties: The process results in a rough, slightly scaled surface. Hot-rolled plates have excellent toughness and are more ductile. They are generally less expensive than cold-rolled plates and are available in a wider range of thicknesses.

Applications: Structural supports, railroad cars, agricultural equipment, and any application where a precise surface finish is not critical.

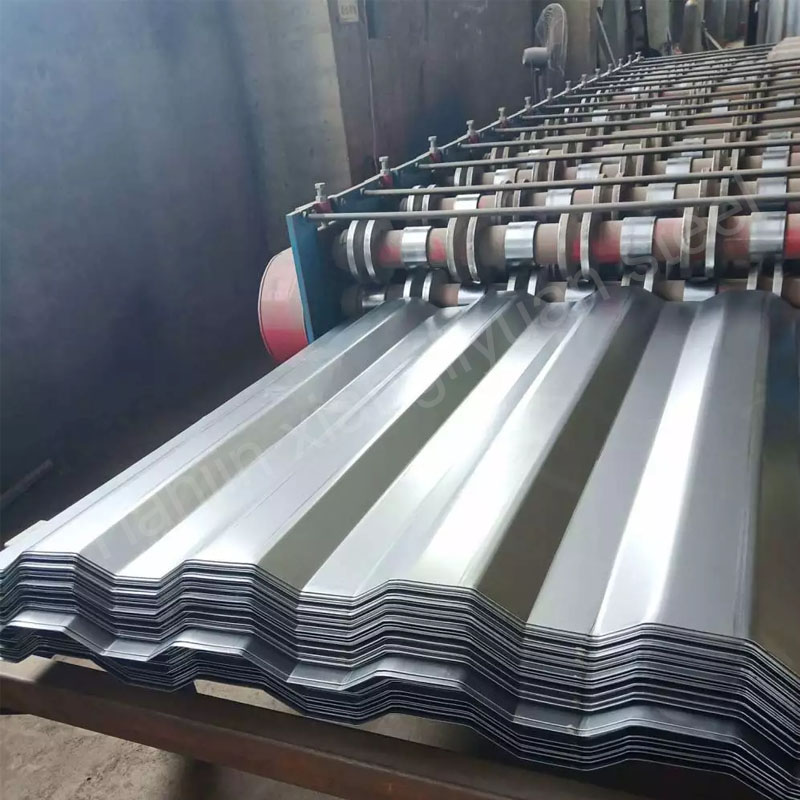

2. Cold Rolled Steel (CR) Plates / Cold Worked Plates

Cold rolling is performed at or near room temperature. The hot-rolled steel is further processed through rollers to achieve the final dimensions.

Properties: This process produces plates with a smooth, polished surface finish and very tight dimensional tolerances. It increases the strength and hardness of the steel through “strain hardening” but reduces its ductility. While “cold-rolled” typically refers to sheets and coils, thicker plates can undergo a similar process called “cold finishing.”

Applications: Applications requiring a high-quality surface finish, such as automotive body panels, appliance exteriors, and precision parts.

III. Classification by Microstructure and Heat Treatment

The microstructure of steel, determined by its chemical composition and thermal history, defines its mechanical properties.

1. Normalized Steel Plates

The plate is heated to a high temperature and then air-cooled. This refines the grain structure, resulting in a uniform microstructure with improved toughness and strength compared to as-rolled steel.

2. Annealed Steel Plates

The plate is heated and then cooled very slowly in a furnace. This process softens the steel, relieves internal stresses, and improves ductility and machinability, making it easier to work with.

3. Quenched and Tempered (Q&T) Steel Plates

This is a two-step heat treatment process used primarily on medium-carbon and alloy steels to achieve very high strength-to-weight ratios.

Quenching: The steel is heated and then rapidly cooled in water or oil, creating a very hard but brittle martensitic structure.

Tempering: The quenched steel is reheated to a lower temperature to reduce brittleness and relieve stresses, resulting in a fine balance of high strength, hardness, and good toughness.

Common Grades: ASTM A514, AR400, AR500 (Abrasion Resistant grades).

Applications: Military armor, mining equipment, bulldozer blades, and other high-wear, high-impact applications.

IV. Classification by Deoxidation Practice

This classification relates to the steelmaking process and affects the internal soundness and suitability for specific applications, particularly welding.

1. Rimmed Steel

An incompletely deoxidized steel that results in a relatively pure outer “rim” and a carbon/segregate-rich core. It is not commonly used for plates today due to its non-uniformity.

2. Capped Steel

A variation of rimmed steel, offering a compromise between rimmed and killed steel.

3. Semi-Killed Steel

A partially deoxidized steel with a level of uniformity between rimmed and killed steel. It is often used for structural sections.

4. Killed Steel

The steel is fully deoxidized by adding elements like silicon or aluminum. This results in a homogeneous, uniform internal structure with minimal gas porosity.

Properties: Killed steel has more uniform chemical and mechanical properties throughout the plate, making it superior for forging, carburizing, and most importantly, for critical welding applications. Most carbon steel plates for structural and pressure vessel use are killed steel.

Common Grades: ASTM A516 (Pressure Vessel Quality), most ASTM A36 plates are also fully killed.

V. Classification by Quality and Application Standards

Carbon steel plates are often defined by industry-specific standards that dictate their chemical composition, mechanical properties, and quality.

Structural Steel Plates (e.g., ASTM A36, ASTM A572): Designed for building bridges, buildings, and other structures. They prioritize strength and weldability.

Pressure Vessel Quality (PVQ) Plates (e.g., ASTM A516, ASTM A387): Manufactured to withstand high pressures and temperatures. They undergo stringent testing to ensure internal soundness and notch toughness.

Abrasion Resistant (AR) Steel Plates (e.g., AR400, AR500, Hardox): A class of high-strength, quenched and tempered steels specifically designed to resist wear and abrasion in demanding environments.

Shipbuilding Steel Plates (e.g., ABS Grade A, AH36): Certified by classification societies like ABS, DNV, or LR for use in marine environments. They offer good toughness and corrosion resistance.

Carbon Steel Floor Plate: Often with a raised lug pattern for slip resistance, used for industrial flooring, stair treads, and work platforms.

Choosing the Right Carbon Steel Plate

Navigating the classifications of carbon steel plates can be complex, but it is essential for project success. The right choice depends on a careful evaluation of your requirements for:

Strength and Hardness

Ductility and Toughness

Weldability and Formability

Surface Finish

Cost-Efficiency

Environmental Conditions (Abrasion, Impact, Temperature)

As your trusted carbon steel plate supplier-Tianjin xiangliyuan steel, we offer a comprehensive inventory covering all these classifications—from standard ASTM A36 hot-rolled plates to high-performance quenched and tempered AR500 abrasion-resistant plates. Our technical experts are here to help you select the perfect grade for your specific application, ensuring optimal performance, durability, and value.

Contact us today for a quote or to speak with our specialists about your carbon steel plate needs.