Structural steel tubes are indispensable components in modern construction, manufacturing, and infrastructure projects. Among these, welded structural tubes—including square steel tubes, ERW steel tubes, and specialized products like greenhouse tubes—are widely used due to their versatility, strength, and cost-effectiveness. This article explores their materials, international standards, common specifications, and key applications, providing essential insights for engineers, architects, and industry professionals.

1. Introduction to Welded Structural Steel Tubes

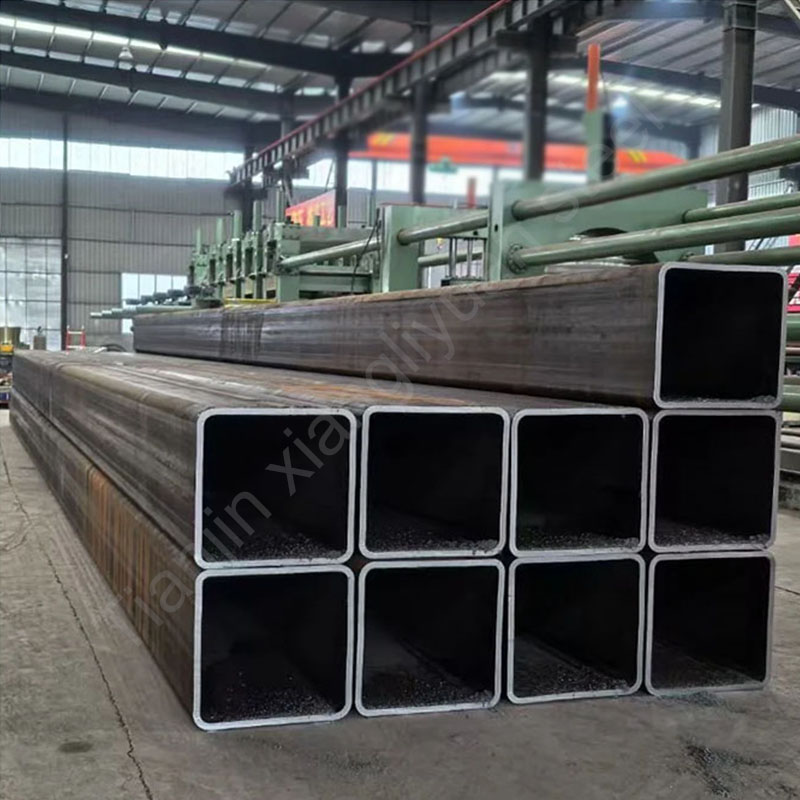

Welded structural tubes are manufactured by forming steel coils or sheets into desired shapes (round, square, rectangular) and welding the seams using advanced techniques like Electric Resistance Welding (ERW). These tubes are favored for their uniformity, dimensional accuracy, and adaptability to diverse industrial needs. Common types include:

Square Steel Tubes: Known for their high torsional strength and aesthetic appeal.

ERW Steel Tubes: Cost-effective and suitable for high-pressure applications.

Greenhouse Tubes: Lightweight, corrosion-resistant tubes designed for agricultural frameworks.

2. Material Grades and Steel Specifications

The performance of welded structural tubes depends on the steel grade used. Below are the most common materials:

Carbon Steel Grades

ASTM A500 Grade B/C:

Widely used for structural applications.

Tensile strength: 58,000–70,000 psi (Grade B); 62,000–78,000 psi (Grade C).

Suitable for square and rectangular tubes in construction.

ASTM A36:

General-purpose carbon steel with excellent weldability.

Yield strength: 36,000 psi.

ASTM A53 Grade B:

Used for ERW steel tubes in plumbing and mechanical systems.

Yield strength: 35,000 psi.

International Standards

EN 10219 (Europe): Covers cold-formed welded structural hollow sections (S235JR, S275JR, S355JR).

JIS G3444 (Japan): Specifies STK400, STK500, and STK490 for mechanical structures.

GB/T 6728 (China): Includes Q195, Q235, and Q345B grades for square and rectangular tubes.

3. International Standards for Structural Tubes

Compliance with regional standards ensures quality and interoperability. Key standards include:

North America (ASTM/ASME)

ASTM A500: Standard for cold-formed welded carbon steel structural tubing.

ASTM A513: Covers ERW mechanical tubing.

ASME SA500: Pressure-rated tubes for boilers and pipelines.

Europe (EN)

EN 10219: Cold-formed welded structural hollow sections.

EN 10255: Non-alloy steel tubes for welding and threading.

Asia-Pacific

JIS G3444 (Japan): General-purpose carbon steel tubes.

GB/T 3091 (China): Welded steel pipes for low-pressure fluid transport.

4. Common Sizes and Dimensions

Welded structural tubes are available in standardized sizes to meet global demand:

Square Steel Tubes

Size Range: 20×20 mm to 500×500 mm.

Wall Thickness: 1.2 mm to 16 mm.

Common Applications: Frames, supports, and architectural designs.

ERW Steel Tubes

Diameter: 1/2″ to 24″.

Wall Thickness: 0.5 mm to 12.7 mm.

Standards: ASTM A53, ASTM A135.

Greenhouse Tubes

Size: Typically 25×25 mm to 50×50 mm (square) or 25×50 mm (rectangular).

Thickness: 1.0 mm to 2.5 mm (galvanized or coated for corrosion resistance).

5. Key Applications of Welded Structural Tubes

The adaptability of these tubes makes them ideal for:

Construction and Infrastructure

Building frameworks, roof trusses, and columns (using square steel tubes).

Scaffolding and temporary structures (ERW tubes).

Agriculture and Greenhouse Projects

Greenhouse tubes form durable frameworks for polyhouses and shade nets.

Corrosion-resistant coatings extend lifespan in humid environments.

Automotive and Machinery

Roll cages, chassis, and hydraulic systems (high-strength ERW tubes).

Energy and Utilities

Oil and gas pipelines (API 5L-compliant ERW tubes).

Solar panel mounting structures (galvanized square tubes).

6. Advantages of Welded Structural Tubes

Cost Efficiency: ERW and square tubes reduce material waste.

Customization: Available in bespoke sizes and coatings (e.g., galvanized, painted).

Sustainability: Recyclable and energy-efficient production processes.

7. Selecting the Right Tube for Your Project

Consider these factors:

Material Grade: Match strength requirements (e.g., ASTM A500 for heavy loads).

Standards Compliance: Ensure adherence to local regulations (e.g., EN 10219 in Europe).

Environmental Conditions: Use galvanized or coated tubes for outdoor/greenhouse use.

8. Conclusion

From square steel tubes in skyscrapers to greenhouse tubes in agriculture, welded structural tubes are foundational to modern industry. By understanding material grades, international standards, and sizing options, businesses can optimize their projects for durability, compliance, and cost.

For premium-quality ERW steel tubes, square steel tubes, or customized greenhouse tubes, explore our catalog to find solutions tailored to your needs.