Look around you. From the warmth of your home on a winter morning to the electricity powering your screen, there’s a high probability that energy traveled hundreds, if not thousands, of miles to reach you. This incredible journey often happens silently, unseen, through the veins of modern infrastructure: pipelines. And at the heart of these critical arteries lies a remarkable material – L415 or X60 grade pipeline steel. This isn’t just another piece of metal; it’s a testament to human engineering, designed for resilience, safety, and efficiency.

For decades, the global quest for energy has pushed the boundaries of material science. We need to transport oil and natural gas from remote, often harsh, reservoirs to bustling cities and industries. The pipes used must withstand immense internal pressures, the weight of the earth above them, corrosive elements, and temperature extremes, all while maintaining absolute integrity for decades. This is where the specific, demanding role of grades like L415/X60 comes into brilliant focus.

Understanding the Nomenclature: More Than Just a Code

First, let’s decode the name. You might see it as L415 according to the API 5L standard (American Petroleum Institute) or as X60 following the ISO 3183 norm. They are essentially two sides of the same coin. The ‘L’ stands for ‘Line pipe’, ‘415’ indicates the minimum yield strength in Megapascals (MPa). The ‘X’ series is similar, with ’60’ representing 60,000 psi yield strength. This specified minimum yield strength (SMYS) is the cornerstone. It means the steel is engineered to resist permanent deformation up to this tremendous pressure level, forming the primary basis for pipeline design. Choosing the right grade is a calculated balance between strength, weldability, toughness, and cost-effectiveness, making L415/X60 a perennial favorite for a vast range of onshore and offshore applications.

The Alchemy of Strength: What Makes L415/X60 Special?

Creating steel that is both incredibly strong and reliably ductile is an alchemy of precise metallurgy. L415/X60 is typically a micro-alloyed steel. This means that besides the basic iron and carbon, small, strategic amounts of elements like Niobium (Nb), Vanadium (V), and Titanium (Ti) are added. These are the unsung heroes.

During the controlled thermo-mechanical processing (like hot rolling or forming), these micro-alloys form fine carbonitride particles. They inhibit grain growth. The result? A much finer grain structure in the final steel. In metallurgy, finer grains are synonymous with improved toughness, better strength, and superior resistance to cracking. It’s like the difference between a structure built with large, uneven bricks versus one with small, uniform, and tightly packed blocks—the latter is far more robust.

This refined microstructure gives L415/X60 its key personality traits:

High Strength-to-Weight Ratio: It allows for the use of thinner pipe walls while maintaining pressure ratings, leading to significant savings in material, transportation, and installation costs.

Exceptional Toughness: Especially at low temperatures. Pipelines crossing Arctic regions or deep-sea floors cannot become brittle. The controlled chemistry and processing ensure the steel can absorb energy and resist fracture propagation.

Excellent Weldability: A pipe is only as strong as its weld. The chemical composition of X60 is carefully balanced to allow for smooth, reliable field welding, creating seamless, homogeneous joints that are as strong as the pipe body itself.

Superior Resistance to Deformation: It can resist the forces of bending during installation and the long-term geological shifts, like soil movement or seismic activity.

Where the Rubber Meets the Road: Applications in the Real World

Imagine a pipeline snaking across the Siberian permafrost, or lying on the dark bed of the North Sea. These are not hypotheticals. L415/X60 steel pipes are the workhorses in such environments.

Onshore Transmission Networks: They form the main trunk lines, carrying hydrocarbons from production fields to refineries and distribution hubs across continents.

Gathering Systems: In oil and gas fields, clusters of smaller-diameter X60 pipes gather product from multiple wells.

Offshore Pipelines: Resisting the corrosive seawater and high pressures, these pipes are essential for subsea developments.

Structural Applications: Their reliable strength also makes them suitable for construction piling, and structural columns in heavy industrial settings.

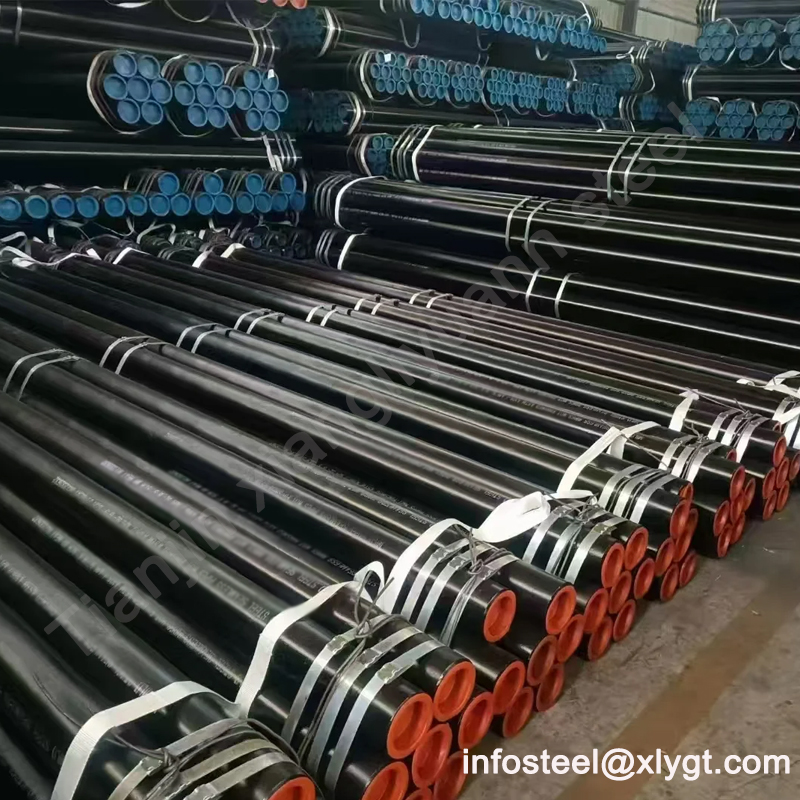

The Tianjin Xiangliyuan Steel Commitment: Crafting Confidence, Not Just Pipe

This is where our story converges with the science. At Tianjin Xiangliyuan Steel, we don’t just manufacture L415/X60 pipe; we engineer confidence. We understand that every length of pipe we produce becomes part of a critical, long-life asset. Our responsibility is immense.

Our philosophy is built on control and transparency. We source high-quality raw materials, the first crucial step in the metallurgical chain. Our advanced manufacturing process employs state-of-the-art JCOE/UOE forming technology for superior dimensional accuracy and consistent wall thickness, followed by full-body expansion to maximize structural integrity. The heat treatment is meticulously controlled to unlock the optimal microstructure that defines true X60 performance.

But for us, the process isn’t complete until it’s verified. Every single pipe undergoes a battery of rigorous tests. This goes beyond standard hydrostatic testing. We conduct full-spectrum non-destructive testing (NDT), including ultrasonic and radiographic inspection, to ensure there isn’t a flaw the size of a pinhead that escapes our notice. We test mechanical properties – yield strength, tensile strength, elongation, and crucially, Charpy V-Notch impact toughness at specified temperatures to guarantee performance in the intended environment. Our in-house laboratory is not just a facility; it’s the guardian of our promise.

Why Partner with Tianjin Xiangliyuan Steel?

In a global market, choice is abundant. But partnership is distinct. Choosing Tianjin Xiangliyuan Steel means choosing a collaborator who views your project’s success as its own.

Depth of Expertise: We specialize in high-grade line pipe. Our technical team lives and breathes the specifications, challenges, and innovations of pipeline engineering.

Flexibility & Responsiveness: Need specific wall thicknesses, unusual diameters, or stringent supplemental requirements? We engage in a technical dialogue to tailor our product to your precise project needs, rather than offering a one-size-fits-all solution.

Uncompromising Integrity: Our name on the pipe is our bond. We provide full traceability and certified Mill Test Reports (MTRs) that document the journey of your steel from melt to mill.

Global Logistics Mastery: Based in Tianjin, a major industrial and port hub, we have streamlined the complex process of packaging, warehousing, and shipping to ensure your pipes arrive on site, anywhere in the world, on time and in perfect condition.

Your Project, Our Blueprint

We envision our role as more than a supplier. When you contact us at infosteel@xlygt.com with your project specifications or even just a concept, we engage as a resource. Our engineers can provide insights on grade selection, applicable standards, and logistical planning. That initial email is the first step in building the reliable, invisible backbone for your next major energy or infrastructure project.

The story of global energy is written in steel. It’s a story of reaching further, enduring longer, and doing so safely. L415/X60 grade steel is a pivotal chapter in that story, enabling the ambitious pipelines that power nations. At Tianjin Xiangliyuan Steel, we are committed to authoring that chapter with excellence, one meticulously crafted, thoroughly tested pipe at a time. Let’s build the vital connections for tomorrow, together.

Reach out today: For technical data sheets, to discuss an upcoming project, or to learn how our L415/X60 pipeline steel can form the foundation of your success, please contact our team at infosteel@xlygt.com. Let Tianjin Xiangliyuan Steel be your trusted partner in strength.