If you’ve ever marvelled at the smooth, powerful, and silent extension of a hydraulic cylinder in heavy machinery, or relied on the precise, unwavering movement in a high-performance industrial press, you’ve witnessed the quiet work of a masterpiece often overlooked: the honed tube. This isn’t just “another piece of pipe.” It’s the very heart of linear motion systems, the critical chamber that dictates efficiency, longevity, and reliability. At Tianjin Xiangliyuan Steel, we don’t just manufacture honed tubes; we craft the foundational integrity for machinery across the globe.

Think of it this way: the piston seal inside your cylinder is a superstar athlete. But even the greatest athlete needs a perfect track to perform on. A rough, uneven, or inconsistent surface creates friction, wears the athlete out prematurely, and leads to a breakdown. A honed tube is that perfectly prepared track. It’s the meticulously finished interior surface that allows seals to glide with minimal friction, maintaining perfect lubrication, preventing leaks, and ensuring every ounce of hydraulic force is translated into smooth, controlled movement.

So, What Exactly is a Honed Tube?

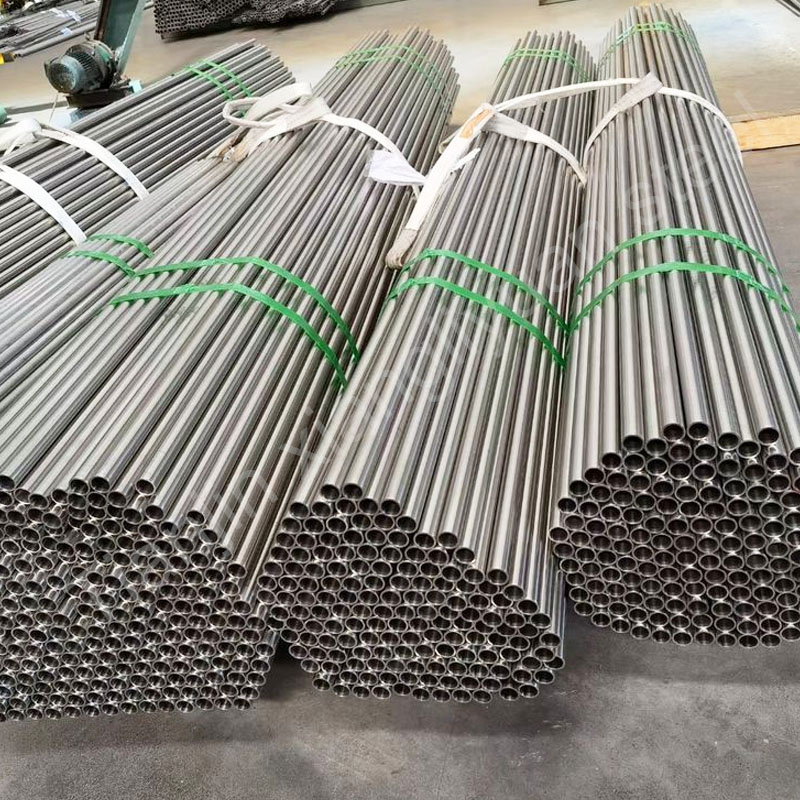

In simple terms, a honed tube is a cold-drawn or seamless steel tube that has undergone a precision finishing process called honing. This isn’t merely polishing. Honing is an abrasive process that removes a precise amount of material from the inner diameter (ID) to achieve several non-negotiable characteristics:

Superior Surface Finish: We’re talking about a mirror-like, cross-hatched pattern. This isn’t for aesthetics. The cross-hatch pattern is deliberate—it traps hydraulic oil, ensuring continuous lubrication of the piston seal throughout its stroke. This drastically reduces wear and tear on both the tube and the seal. A rough surface would scrape the seal away; our finish protects it.

Exceptional Dimensional Accuracy: Consistency is king. The ID of a honed tube must be held to extremely tight tolerances along its entire length. Any variance—tapering, waviness, or out-of-roundness—creates gaps for pressure loss and causes the piston to “chatter” or stick. Our precision ensures the piston moves as if on rails.

Optimal Straightness: Imagine pushing a piston through a slightly bent tube. The binding, the uneven wear, the energy loss—it’s a recipe for failure. Honed tubes are carefully straightened to ensure true linear motion, which is, after all, the entire point of a hydraulic cylinder.

The “Why” Behind the Shine: Applications That Depend on Honed Tubes

You’ll find our honed tubes where performance cannot be compromised:

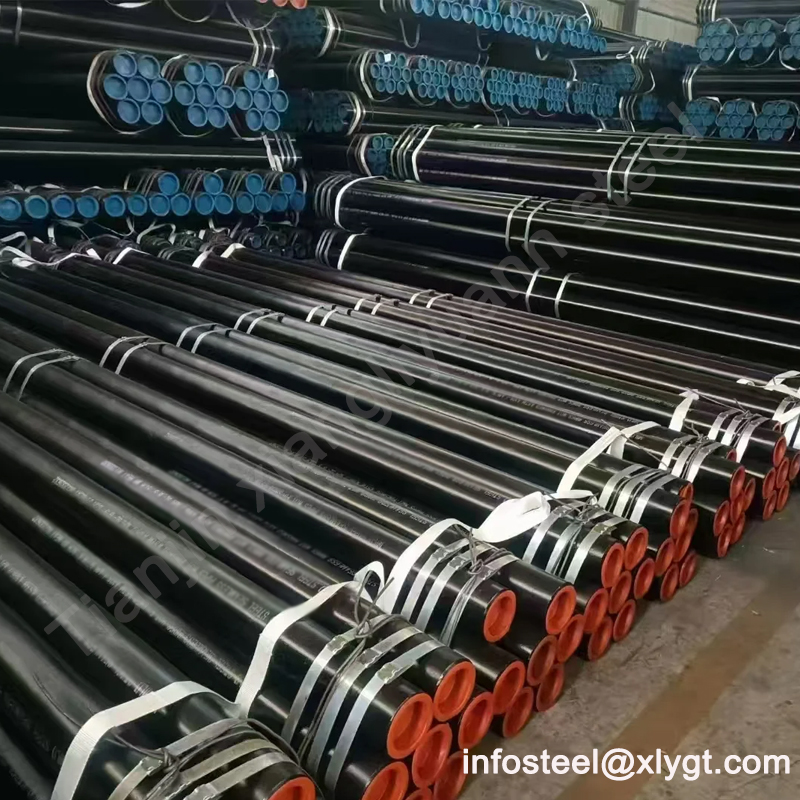

Construction & Mining (Excavators, Bulldozers, Drilling Rigs): These giants face dirt, grit, and immense shock loads. A subpar tube leads to cylinder failure, costing thousands in downtime. Our tubes provide the rugged, reliable interior needed to withstand these brutal environments.

Agricultural Machinery (Tractors, Harvesters): Reliability during short seasonal windows is critical. A leaking, sluggish cylinder can delay an entire harvest. The smooth surface of a Xiangliyuan honed tube ensures consistent performance season after season.

Material Handling (Forklifts, Cranes, Presses): Precision and safety are paramount. The controlled motion provided by a precision-honed tube is essential for accurate lifting, positioning, and pressing.

Industrial Automation and Robotics: This is where precision meets speed. Robotic arms require fast, frictionless, and repeatable movements. Any stick-slip effect from a poor tube surface ruins accuracy and efficiency.

Beyond the Spec Sheet: The Tianjin Xiangliyuan Steel Difference

Many suppliers can quote a standard size. At Tianjin Xiangliyuan Steel, we understand that the real world rarely fits a standard mold. Our approach is different. We start by listening.

We’ve built our reputation not just on what we make, but on how we make it and why. It begins with meticulous raw material selection. We source only quality-controlled, homogeneous steel, because you cannot create a perfect interior from imperfect stock. Our cold drawing process ensures excellent initial straightness and wall consistency, setting the stage for the honing operation.

Then comes the art within the science: our honing process. It’s controlled by experienced technicians who understand that different applications demand different finishes. A tube for a high-speed robotic application might need a different surface profile than one for a slow, high-force mining cylinder. We tailor the process. The result is a tube that doesn’t just meet ISO or ASTM standards on paper, but exceeds them in practice, delivering seamless performance in your specific application.

Furthermore, we offer more than just the honing. Our integrated process allows us to provide:

Custom Sizing: Need an unusual OD, ID, or wall thickness? We can engineer it.

Material Expertise: From standard ST52, to wear-resistant 1045, to stainless steel grades for corrosive environments, we guide you to the right material.

Additional Finishing: We can provide cutting, chamfering, threading, and other secondary operations, delivering a more component-ready product.

A Partnership, Not Just a Purchase

Choosing your honed tube supplier is a critical decision. It’s a choice that affects your product’s performance, your brand’s reputation for reliability, and your bottom line through reduced warranty claims and downtime. We believe in building partnerships. When you work with Tianjin Xiangliyuan Steel, you gain access to our technical team’s deep expertise. We’re here to help you solve problems, not just fill an order.

Perhaps you’re troubleshooting premature seal wear. Maybe you’re designing a new machine and need guidance on tube specs. Or you might be looking for a more reliable supply chain for your critical components. These are the conversations we excel at.

Let’s Build Something Remarkable Together

The journey of a honed tube, from a raw steel blank to the precision-engineered heart of a powerful machine, is one we are passionate about. It’s a journey that requires skill, technology, and an unwavering commitment to quality.

If your projects demand linear motion that is smooth, strong, and silent—motion you can depend on—then the foundation of that motion should be a honed tube from a partner you can trust.

We invite you to experience the Tianjin Xiangliyuan Steel difference. For technical specifications, to discuss a custom project, or simply to have a conversation with our engineering team about your requirements, please reach out. Let’s connect and explore how we can contribute to the success of your next project.

Contact us today at: infosteel@xlygt.com

Tianjin Xiangliyuan Steel – Crafting the Precision Behind the Power.