From the skyscrapers that define our skylines to the energy that powers our homes and the water that flows from our taps, steel pipes are the unsung heroes of modern civilization. As a leading steel pipe manufacturer in China, we understand that this fundamental product is more than just a commodity; it’s a critical component engineered for strength, durability, and reliability.

Choosing the right type of steel pipe for your project is crucial. This comprehensive guide will walk you through the different types of steel pipes, their manufacturing processes, key applications, and the international quality standards that define them. Our goal is to empower you with the knowledge to make an informed decision for your next project.

Chapter 1: Understanding the Basics – What Are Steel Pipes and Tubing?

While the terms “pipe” and “tube” are often used interchangeably, there is a key technical distinction.

Steel Pipe is primarily used for transporting fluids and gases. It is categorized by its Nominal Pipe Size (NPS) and Schedule (which defines wall thickness). Its main function is pressure integrity and corrosion resistance.

Steel Tube is often used for structural applications (e.g., scaffolding, handrails, mechanical parts) and is specified by its exact outside diameter and wall thickness. Its main function is structural strength and precision.

In this article, we will focus on steel pipes, the workhorses of industrial and construction applications.

A Deep Dive into Steel Pipe Manufacturing Processes

The manufacturing method significantly impacts a pipe’s characteristics, pressure rating, and cost. The two primary methods are Seamless and Welded.

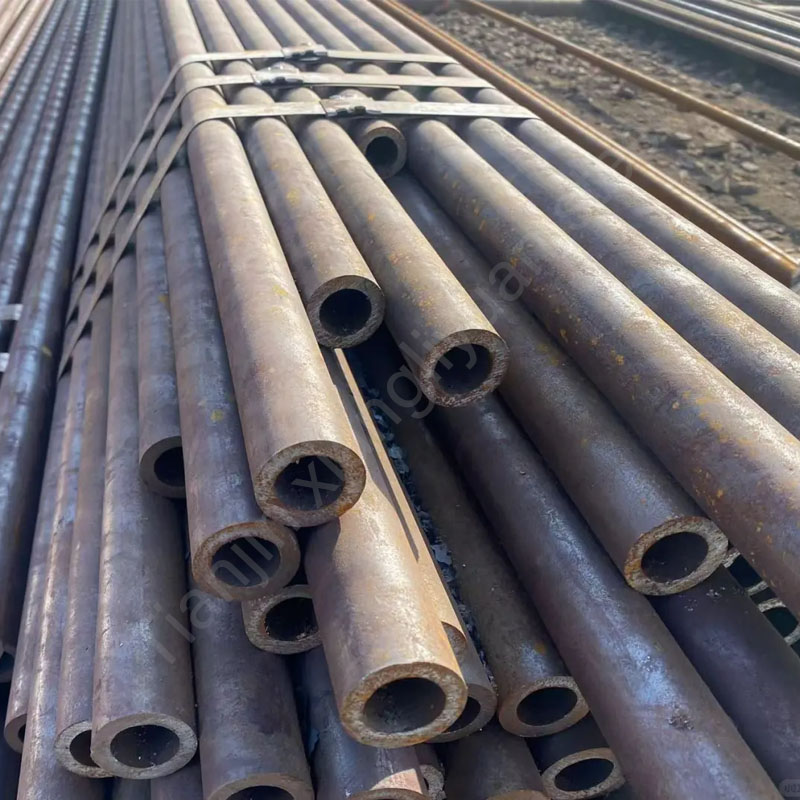

2.1. Seamless Steel Pipe (SMLS)

As the name implies, seamless steel pipes are manufactured without a seam or weld-joint. A solid cylindrical steel billet is heated and pierced through the center to form a hollow tube. It is then elongated and rolled to achieve the desired diameter and wall thickness.

Key Advantages:

Superior Strength: The absence of a weld seam eliminates a potential point of weakness, making it stronger under high pressure.

Uniformity: The wall thickness is more consistent around the circumference.

Corrosion Resistance: With no weld, there is less risk of corrosion starting at a seam.

Common Applications: High-pressure applications like oil and gas pipelines, power plants, chemical processing, and hydraulic systems.

2.2. Welded Steel Pipe

Welded steel pipes are made by rolling a steel coil or plate into a cylindrical shape and welding the seam. The two most common types are ERW and SAW.

A. Electric Resistance Welding (ERW Pipe)

In the ERW process, the edges of the steel strip are heated by an electric current and fused together under pressure without the use of filler metal. Modern high-frequency ERW (HFIW) produces a high-integrity weld that is often indistinguishable from the parent metal.

Key Advantages: Cost-effective, high production efficiency, excellent for medium-pressure applications.

Common Applications: Water and gas transmission, fencing, scaffolding, and structural uses.

B. Submerged Arc Welding (SAW Pipe)

For larger diameter pipes, the SAW process is used. The weld arc is submerged under a layer of flux, which prevents spatter and allows for deep penetration, creating an extremely strong weld. SAW pipes can be longitudinal (LSAW) or spiral (SSAW or HSAW).

LSAW Pipe: Made by bending and welding a single steel plate. It is known for its excellent performance in high-pressure, large-diameter transmission pipelines for oil and gas.

SSAW/HSAW Pipe: Made by helically winding a steel coil. It offers great flexibility in diameter and is strong under complex load conditions.

Exploring Common Types of Steel Pipes and Their Coatings

Different environments demand different properties. Here are the most common types of steel pipes we manufacture.

3.1. Carbon Steel Pipes

This is the most widely used type, consisting primarily of iron and carbon. It is strong, durable, and cost-effective. It is the standard for structural and many industrial fluid transport applications.

3.2. Galvanized Steel Pipes

These are carbon steel pipes coated with a layer of zinc to prevent rust and corrosion. The galvanization can be done through hot-dipping or electroplating.

Applications: Water supply lines, fencing, handrails, and outdoor structures exposed to the elements.

3.3. Stainless Steel Pipes

Made from an iron alloy containing a minimum of 10.5% Chromium, stainless steel pipes are highly resistant to corrosion and oxidation. Common grades include 304 (general purpose) and 316 (superior corrosion resistance, ideal for marine environments).

Applications: Food and beverage processing, pharmaceutical industry, chemical plants, and architectural aesthetics.

3.4. Alloy Steel Pipes

These pipes contain additional alloying elements like Molybdenum, Chromium, or Nickel to enhance specific properties such as strength, toughness, and resistance to heat and wear.

Applications: Boiler tubes, high-temperature and high-pressure service in power generation and refineries.

Key Applications – Where Are Steel Pipes Used?

The versatility of steel pipes is unmatched. Here’s a breakdown by industry:

Oil & Gas: Seamless and LSAW pipes are critical for upstream (drilling), midstream (transmission pipelines), and downstream (refining) operations. They must meet stringent standards like API 5L.

Construction & Infrastructure: ERW and galvanized pipes are used for structural frameworks, scaffolding, water and sewage systems, and piling.

Mechanical & Automotive: Precision steel tubes are used in hydraulic cylinders, bearing housings, and vehicle exhaust systems.

Power Generation: Both conventional and nuclear power plants rely on high-quality alloy and carbon steel pipes for boiler tubes, steam lines, and condenser tubes.

Navigating International Quality Standards

For global trade, adherence to international standards is non-negotiable. It ensures quality, safety, and interoperability. As a reputable Chinese manufacturer, our production is certified to the following key standards:

ASTM (American Society for Testing and Materials): A widely used international standard. e.g., ASTM A53 (black and galvanized pipe), ASTM A106 (seamless for high-temperature service), ASTM A500 (structural tubing).

API (American Petroleum Institute): The gold standard for the oil and gas industry. API 5L specifies requirements for pipeline transportation systems.

EN (European Norm): European standards like EN 10219 (cold-formed welded structural hollow sections) are critical for projects in Europe.

DIN (Deutsches Institut für Normung): German standards that are highly respected worldwide.

JIS (Japanese Industrial Standards): Common for projects in Asia.

When sourcing, always specify the required standard to ensure you receive a product fit for your purpose.

Why Source from a Chinese Steel Pipe Manufacturer?

China has been the world’s leading steel producer for decades, and for good reason.

Scale and Capacity: Chinese mills have massive production capacity, ensuring a stable and reliable supply for large-scale global projects.

Technical Expertise: Decades of focus on the steel industry have resulted in deep technical knowledge and advanced manufacturing capabilities.

Cost-Effectiveness: Economies of scale, efficient logistics, and a robust supply chain make Chinese steel pipes highly competitive without compromising on quality.

Quality Assurance: Leading manufacturers, like us, invest heavily in state-of-the-art quality control labs with spectrometers, ultrasonic testers, hydrostatic testers, and more to ensure every batch meets international standards.

How to Choose the Right Supplier

Not all manufacturers are created equal. Here are key factors to consider:

Certifications: Look for ISO 9001, API Monogram, and specific ASTM/EN certifications.

Production & Testing Capability: Inquire about their manufacturing processes and in-house testing equipment (e.g., ultrasonic, hydrostatic, eddy current testing).

Experience & Reputation: How long have they been in business? Can they provide references or case studies?

Logistics & Service: Do they have experience in handling international shipping and documentation?

Partnering for Strength and Durability

Steel pipes are a critical investment in the safety, longevity, and success of your project. Understanding the nuances between seamless and welded, carbon and stainless, and the relevant quality standards is the first step to making the right choice.

As a trusted steel pipe and tube supplier -Tianjin xiangliyuan steel, we are committed to more than just selling a product. We are your partner in engineering, providing technical support and high-quality, certified pipes that you can rely on.

Ready to discuss your project requirements?

[Contact Tianjin xiangliyuan steel Today] for a competitive quotation and let our experts help you find the perfect steel pipe solution.