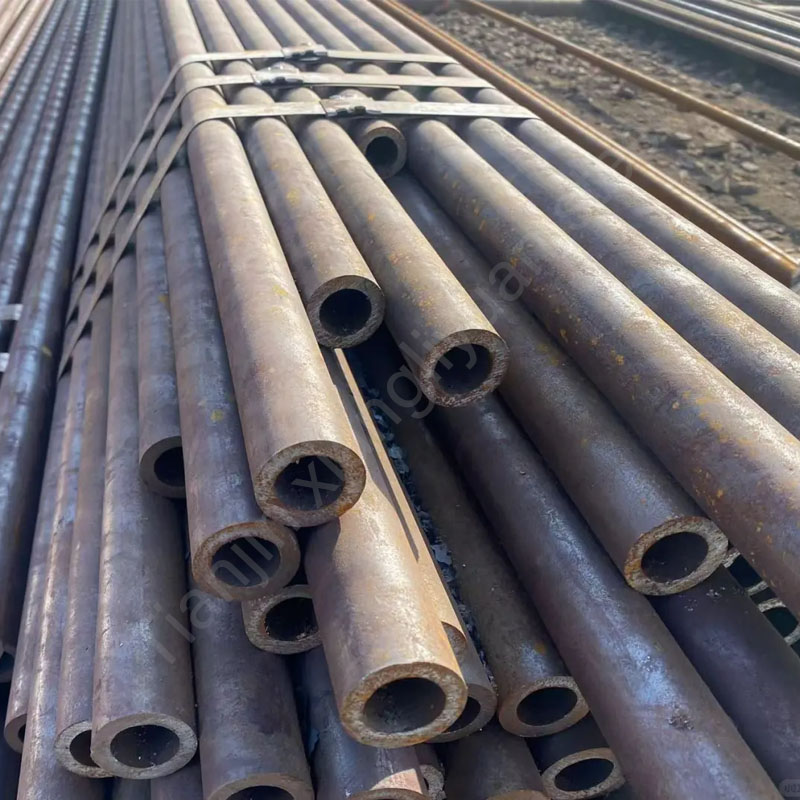

High pressure chemical fertiliser pipes are critical components in modern agricultural and industrial fertilizer production systems. Designed to withstand corrosive chemicals, extreme pressures, and elevated temperatures, these specialized pipes ensure safe and efficient transportation of raw materials like ammonia, urea, phosphoric acid, and nitrogen compounds. In this guide, we explore the technical specifications, international standards, material grades, and applications of chemical fertilizer pipes.

1. Key Materials & Steel Grades for Fertilizer Pipes

1.1 Austenitic Stainless Steels

316/316L (UNS S31600/S31603): Superior chloride resistance for marine fertilizer applications

304L (UNS S30403): General-purpose corrosion resistance

317L (UNS S31703): Enhanced molybdenum content for acidic environments

1.2 Duplex Stainless Steels

2205 (UNS S32205): Ideal for high-pressure urea and ammonia services

2507 (UNS S32750): Superior stress corrosion cracking resistance

1.3 Carbon Steels

ASTM A106 Gr B: High-temperature seamless pipes

API 5L X42/X52: For non-corrosive fertilizer gas transmission

1.4 Special Alloys

Inconel 625 (UNS N06625): Extreme corrosion resistance

Hastelloy C276: For phosphoric acid processing

2. Classification of Chemical Fertilizer Pipes

2.1 By Manufacturing Method

Seamless Pipes (ASTM A312, A358)

ERW (Electric Resistance Welded) Pipes

SAW (Submerged Arc Welded) Pipes

2.2 By Pressure Rating

Class 150 to Class 2500 (ASME B16.34 standards)

2.3 By Coating Type

3LPE Coated: 3-layer polyethylene anti-corrosion

FBE Coated: Fusion-bonded epoxy coating

Galvanized: Zinc coating for external protection

3. International Standards & Certifications

| Region | Key Standards | Application Scope |

|---|---|---|

| USA | ASTM A312, ASME SA358 | Seamless/welded stainless pipes |

| Europe | EN 10216-5, EN 10217-7 | Pressure vessel steel pipes |

| Japan | JIS G3459, JIS G3468 | Urea and ammonia service |

| China | GB/T 14976, GB 6479 | High-pressure fertilizer grade |

| International | ISO 9330-5, NACE MR0175 | Corrosion-resistant requirements |

4. Standard Specifications & Dimensions

4.1 Common Sizes

| Nominal Bore (NPS) | Outer Diameter (mm) | Wall Thickness (Schedule) |

|---|---|---|

| 1/2″ | 21.3 mm | Sch 40, Sch 80, Sch 160 |

| 2″ | 60.3 mm | Sch 10S to Sch 160 |

| 6″ | 168.3 mm | Sch 40 to Sch XXS |

| 12″ | 323.9 mm | Sch 20 to Sch 120 |

4.2 Pressure-Temperature Ratings

ASME B31.3 Process Piping Guidelines

Typical working pressures: 150 PSI to 2500 PSI

Temperature range: -50°C to 450°C (material-dependent)

5. Critical Applications in Fertilizer Industry

5.1 Nitrogen-Based Fertilizers

Anhydrous ammonia transfer lines

Urea synthesis reactor feed pipes

Nitric acid concentration systems

5.2 Phosphatic Fertilizers

Wet-process phosphoric acid pipelines

Sulfuric acid dilution networks

Triple superphosphate (TSP) slurry transport

5.3 Potassium Fertilizers

Muriate of potash (MOP) brine lines

Potassium sulfate crystallization systems

5.4 Compound Fertilizers

NPK slurry distribution manifolds

Granulation plant steam-jacketed pipes

6. Selection Criteria for Optimal Performance

Chemical Compatibility: Match materials to pH levels and chemical constituents

Pressure Requirements: Consider surge pressures and safety factors

Temperature Extremes: Account for thermal expansion/contraction

Flow Characteristics: Prevent crystallization/blockage with proper sizing

Compliance Needs: Meet local regulations (EPA, REACH, OSHA)

7. Maintenance & Inspection Protocols

NDT Methods: Ultrasonic testing, radiography, dye penetrant inspection

Corrosion Monitoring: ER probes, LPR techniques

Cleaning Procedures: Pigging systems for scale removal

Replacement Intervals: ASME B31.3 recommended service life guidelines

8. Global Market Trends (2024)

Rising demand for duplex stainless steel pipes in urea plants

Increased adoption of 3LPE-coated carbon steel pipes for cost efficiency

Growth in large-diameter (24″+ ) pipes for mega fertilizer complexes

Shift toward ISO 21003 multilayer polymer pipes for low-pressure applications

High pressure chemical fertiliser pipes require careful selection of materials, compliance with international standards like ASTM A312 and EN 10216, and proper dimensional specifications to ensure long-term reliability. By understanding the unique demands of nitrogen, phosphate, and potassium fertilizer production, engineers can optimize piping systems for safety, efficiency, and regulatory compliance.