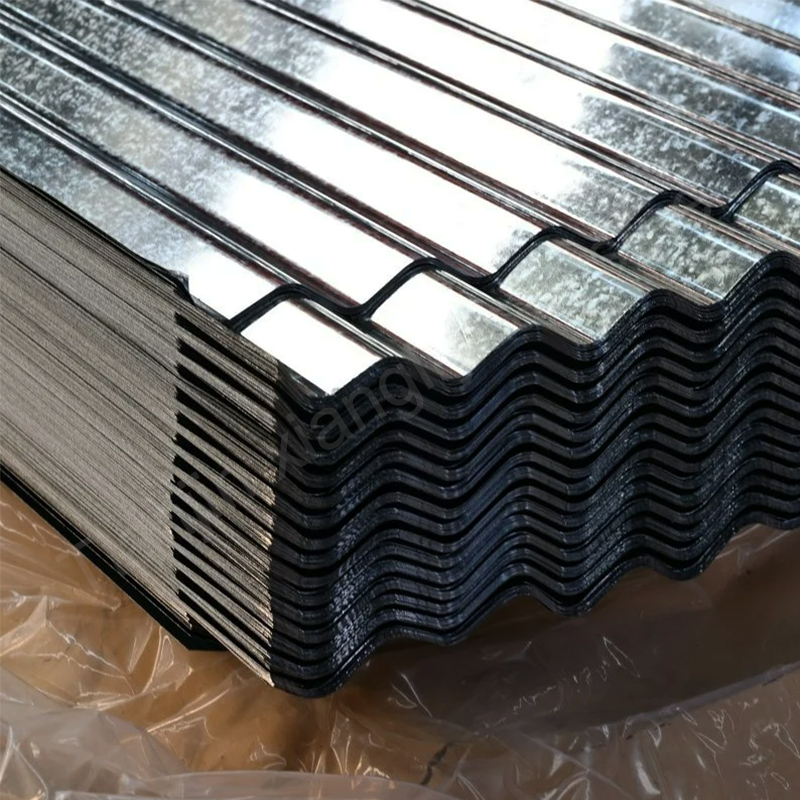

Galvanized corrugated sheet is a steel sheet that is coated with a layer of zinc on the surface of a steel sheet or iron sheet and pressed into a corrugated shape through a special process. Due to the surface galvanizing treatment, galvanized corrugated sheet has significant advantages in corrosion resistance, oxidation resistance and aesthetics, and is widely used in construction, decoration and industrial manufacturing.

1. Material

The material of galvanized corrugated sheet is usually low-carbon steel or galvanized steel coil. The specific materials are mainly:

Q235: This is a common carbon structural steel commonly used in China, with good plasticity and toughness, easy to process and weld.

Q345: Stronger than Q235, suitable for bearing larger loads.

SGCC: This is an international standard grade of hot-dip galvanized steel sheet, with good tensile strength and corrosion resistance, and is often used in occasions with high corrosion resistance requirements.

DX51D+Z: This is a galvanized steel in the European standard, widely used in construction and home appliances.

The choice of material is usually determined according to the specific purpose to ensure the best balance between cost, strength and durability.

2. Tile type

Galvanized corrugated sheet has a rich variety of tile types, and different tile designs are suitable for different uses and aesthetic requirements. Common tile types are mainly the following:

1. Trapezoidal tile

Features: The tile type is trapezoidal, with a significant height difference between the crest and the trough, and the wave height is usually large.

Advantages: Strong load-bearing capacity, suitable for large industrial plants, warehouses and other places that require high strength.

Uses: Commonly used in industrial building roofs and walls.

2. Corrugated tile

Features: The shape is similar to water ripples, and the ripples are continuous and smooth.

Advantages: Classic design, with good drainage performance, suitable for areas with more rain.

Uses: Widely used in the roofs and walls of residential and commercial buildings, especially sloping roofs.

3. Angle tile

Features: The surface of the sheet is V-shaped or pointed corrugated, and the crest is narrow.

Advantages: It has a good three-dimensional sense and visual effect, and is durable.

Uses: It is mostly used in modern style buildings, especially places that emphasize beautiful shapes, such as public buildings and commercial facilities.

4. Concave-convex tile

Features: The surface presents an alternating concave-convex design, and the tile type has a certain artistic sense.

Advantages: It is more beautiful, enhances the strength of the board, and increases the sense of design.

Use: It is usually used in places with high decorative requirements such as exterior wall decoration and garden architecture.

5. Rectangular tile

Features: The crests and troughs are regular rectangular shapes with clear lines.

Advantages: The lines are neat, suitable for modern architectural styles, and easy to match with other decorative materials.

Use: It is mainly used for wall decoration in factories, warehouses and some modern buildings.

6. Curved tile

Features: The crests and troughs are rounder, and the ripples are curved.

Advantages: The curved ripples provide better drainage performance and are visually soft, suitable for residential buildings.

Use: Commonly used in roofs of buildings such as villas and houses that require good drainage functions.

7. Antique tile

Features: The appearance is similar to traditional tiles, with the style of traditional Chinese roof tiles.

Advantages: It has a classical style and beautiful effect, suitable for antique buildings.

Uses: Mostly used in antique buildings, garden buildings or places with Chinese style decoration needs.

The choice of different tile types often depends on the aesthetic needs, drainage needs and structural requirements of the use scenario.

2. International standards

The production and quality control of galvanized corrugated sheets follow a series of standards to ensure the quality and safety of the products. The main standards are:

ASTM A653: This is a US standard that applies to the quality, galvanizing thickness and size requirements of galvanized steel sheets.

JIS G3302: Japanese standard that defines the specifications, properties and test methods of galvanized steel sheets.

EN 10346: European standard for continuous hot-dip galvanized steel sheets for various purposes.

GB/T 2518: This is a Chinese national standard that specifies the size, appearance, coating quality and other requirements of galvanized steel sheets and galvanized steel coils.

These standards have specific parameters in terms of sheet thickness, coating thickness, tensile strength, elongation, etc., to help ensure the reliability and adaptability of galvanized corrugated sheets in different environments.

3. Uses

Galvanized corrugated sheet is widely used in construction, industry and agriculture due to its excellent performance. The main uses include:

Construction field: Galvanized corrugated sheet is often used for roofing and wall materials, especially for industrial buildings such as warehouses, garages, and factories. Its light weight and weather resistance enable it to perform well in various climate conditions. At the same time, the corrugated shape enhances the strength of the sheet and helps to resist wind pressure and snow load.

Agricultural application: In agricultural buildings such as farms, livestock sheds and granaries, galvanized corrugated sheet is an ideal material with excellent corrosion resistance and moisture resistance, and can maintain stability in humid and changeable agricultural environments.

Home decoration: In recent years, galvanized corrugated sheet has gradually been introduced into the field of home decoration, used for background walls and facade decoration, giving the space a unique industrial style.

Transportation facilities: In infrastructure projects such as roads and railways, galvanized corrugated sheet can be used as facilities such as isolation fences and guardrails. Galvanizing improves the rust resistance of the sheet, ensuring safety and durability under long-term outdoor use.

4. Advantages and Disadvantages of Galvanized Corrugated Sheets

Advantages:

Corrosion resistance: The protection of the galvanized layer enables it to effectively resist corrosion factors in the atmosphere and prolong its service life.

Strength and stability: The corrugated design enhances the structural strength of the sheet, making it more durable under conditions such as wind load and snow load.

Convenient construction: Galvanized corrugated sheets are light in weight and easy to install, making them particularly suitable for temporary buildings or projects with high construction time requirements.

Disadvantages:

Relatively high cost: Compared with ordinary steel sheets, galvanized corrugated sheets have a higher manufacturing cost.

Limited aesthetics: In some high-end buildings or areas that require fine decoration, galvanized corrugated sheets may not meet the design requirements.

In summary, galvanized corrugated sheets are highly favored in the construction and industrial fields due to their excellent corrosion resistance and high strength.