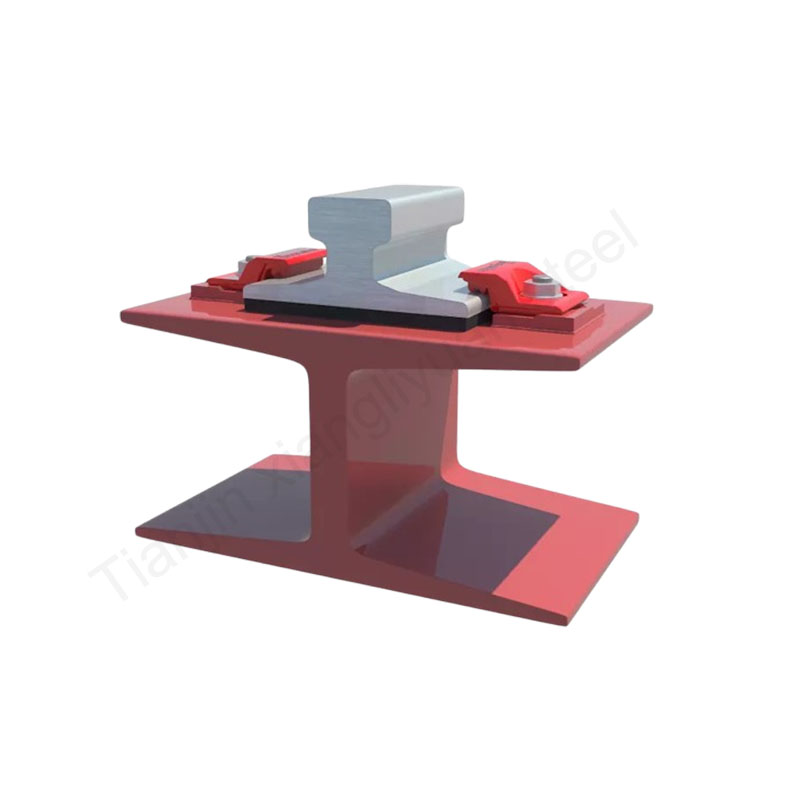

Crane rails are steel rails used to support and guide the operation of lifting equipment (such as bridge cranes, gantry cranes, etc.). Its main function is to carry the weight of the crane and ensure that the crane runs smoothly and safely on the rails.

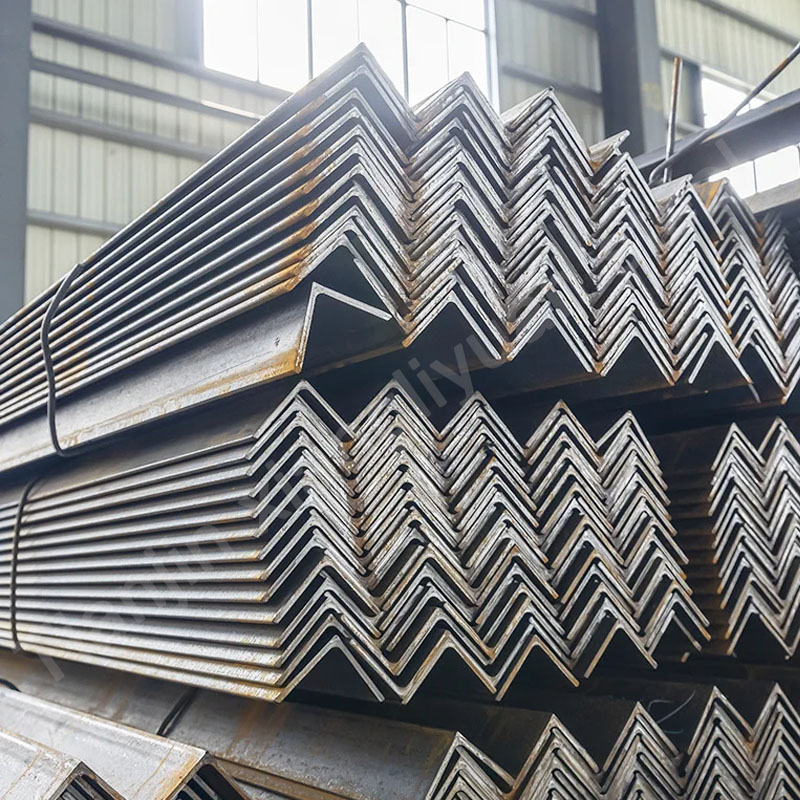

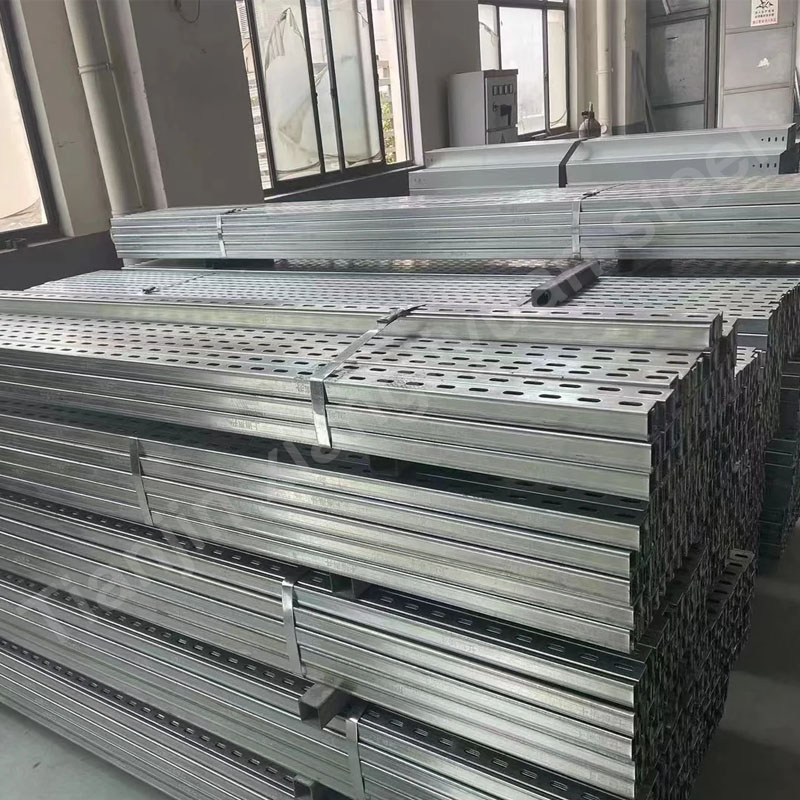

Structure and design: Crane rails are usually made of high-strength steel with good wear resistance and strength. The design of the rails takes into account the weight, movement frequency and environmental factors of the crane. Common rail types include square rails and T-shaped rails. The width and thickness of the rails vary according to specific load requirements.

Function: Crane rails provide a stable running path for lifting equipment, ensuring that the crane can be accurately positioned and move smoothly during operation. The rails are used in conjunction with crane wheels to ensure that the load can be evenly distributed and reduce friction losses.

The steel grades and standards of crane rails vary in different countries and application scenarios, mainly involving the strength, wear resistance and hardness requirements of steel.

Common steel grades

U71Mn (Chinese standard GB/T 11264-2017): This is a commonly used steel grade for crane rails in China, with good strength and wear resistance. Suitable for lifting equipment with large loads.

U75V (Chinese standard GB/T 11264-2017): This steel grade has higher strength and wear resistance and is usually used in heavy crane rail systems with larger loads and more frequent use.

R260 (International standard EN 13674-1): European standard rail steel grade with high strength and wear resistance, suitable for heavy-duty rail systems.

1100 (American standard ASTM A759): This steel grade meets the American crane rail standard, has high strength and toughness, and is suitable for crane systems with frequent operation and high loads.

Related standards

Chinese standard: GB/T 11264-2017 “Crane Rail”: This standard specifies the size, material, performance requirements and related technical specifications of crane rails, and is applicable to the manufacture and use of crane rails in China.

European standard: EN 13674-1 “Railway Track Steel Requirements”: Although this standard is mainly for railway tracks, steel grades such as R260 and R350HT are also used for crane rails, especially in the heavy industry field.

American standard: ASTM A759 “Crane Rail Specification”: This standard is specifically for crane rails and specifies the material, mechanical properties and dimensional requirements of the rails in detail.

Russian standard: ГОСТР 51685-2013: Russia’s standard for crane rails, common steel grades include P50, P65 and P75, which are widely used in the heavy industry field.

Common models of crane rails

According to the standards of different countries and regions, the models of crane rails are also different. Common models include:

China: QU70, QU80, QU100, QU120: The number indicates the weight of the rail per meter (kg), such as QU80 means the weight of the rail per meter is 80kg.

Europe: A55, A65, A75: These models indicate the cross-sectional dimensions of the track and are usually used for light to medium-duty lifting equipment.

USA: CR73, CR100, CR171: The numbers represent the cross-sectional dimensions of the track and are usually used for lifting equipment of different loads.

Crane tracks are widely used in the industrial field, especially in places such as ports, steel mills, shipyards, warehouses and construction sites where heavy objects need to be lifted and transported. Depending on the environment and usage requirements, the tracks can be installed indoors or outdoors, and usually require regular maintenance and inspection.