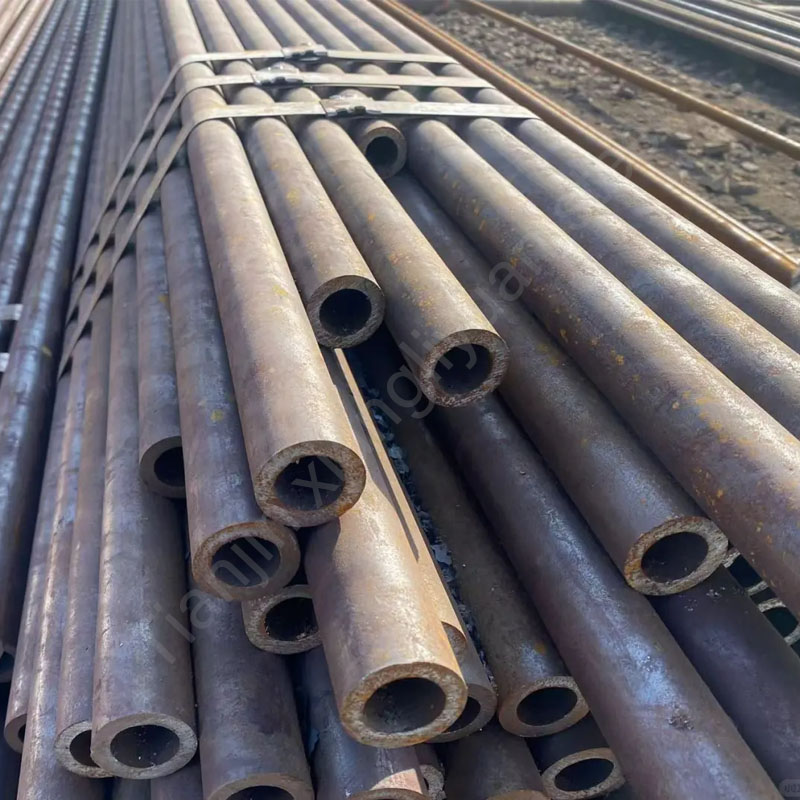

Introduction to Low Temperature Seamless Pipes

Low temperature seamless pipes are specialized steel tubes engineered to perform reliably in extreme sub-zero environments, typically ranging from -50°C (-58°F) to -196°C (-321°F). These pipes are critical for industries such as liquefied natural gas (LNG) processing, cryogenic storage, petrochemical plants, and aerospace, where materials must retain toughness and ductility despite drastic temperature drops. Unlike conventional pipes,Low temperature seamless pipes are designed to prevent brittle fracture, ensuring safety and longevity in applications like LNG transportation, ethylene production, and liquid nitrogen systems.

This article explores the materials, classifications, international standards, dimensions, and applications of low temperature seamless pipes. Whether you’re an engineer, procurement manager, or industry professional, understanding these factors is essential for selecting pipes that meet stringent operational demands.

Key Materials and Steel Grades for Low Temperature Seamless Pipes

The performance of Low Temperature Seamless Pipes depends on their ability to resist brittleness at cryogenic temperatures. Commonly used materials include low-carbon steels, nickel-alloyed steels, and stainless steels, which are optimized for sub-zero environments. Below are the primary steel grades:

1. Carbon and Low-Alloy Steels

ASTM A333 Gr. 1, 3, 6, 7, 8, 9, 10, 11:

Gr. 6 (3.5Ni): The most widely used grade for LNG applications (-45°C to -196°C).

Gr. 3 (1.5Ni): Suitable for temperatures down to -100°C.

Gr. 8 (9Ni): Ultra-low temperature resistance (-196°C), ideal for LNG storage.

ASTM A350 LF2: A carbon steel with impact-tested toughness for -46°C service.

2. Stainless Steels

ASTM A312 TP304/304L, 316/316L: Austenitic stainless steels for moderate cryogenic use (-200°C).

ASTM A358 CL1/CL2: Electric-fusion-welded pipes for cryogenic systems.

3. Nickel Alloys

ASTM B163 Inconel 625: High nickel-chromium-molybdenum alloy for ultra-low temperatures (-269°C).

ASTM B725 UNS N08028: Nickel-iron-chromium alloy resistant to liquid oxygen and nitrogen.

Classification of Low Temperature Seamless Pipes

Low Temperature Seamless Pipes are categorized based on material composition, manufacturing methods, and application-specific requirements:

1. By Material Type

Nickel-Alloyed Steels: ASTM A333 Gr. 6 (3.5% Ni) and Gr. 8 (9% Ni) for LNG and ethylene.

Austenitic Stainless Steels: TP304L/316L for chemical processing.

High-Nickel Alloys: Inconel 625 for aerospace and helium systems.

2. By Manufacturing Process

Cold-Drawn Seamless Pipes: Superior surface finish and dimensional accuracy.

Hot-Extruded Seamless Pipes: Cost-effective for large diameters and thick walls.

3. By Application

LNG Transport and Storage: Pipes for liquefaction plants, tanks, and carrier ships.

Ethylene and Propylene Production: Cryogenic reactors and transfer lines.

Oxygen/Nitrogen Plants: Pipes for air separation units (ASUs).

International Standards for Low Temperature Seamless Pipes

Compliance with global standards ensures quality and safety. Key standards include:

| Standard | Region | Key Specifications |

|---|---|---|

| ASTM A333 | USA | Seamless & welded pipes for low-temp service. |

| ASTM A350 | USA | Carbon steel forgings for sub-zero environments. |

| EN 10216-4 | Europe | Seamless tubes for low temps (P460NL1, etc.). |

| JIS G3460 | Japan | STPL 380/450 for LNG and cryogenic systems. |

| GB/T 18984 | China | Seamless pipes for low-temperature service. |

| ASME SA-333 | Global | Aligns with ASTM for international projects. |

Standard Dimensions and Specifications

Low temperature seamless pipes are available in a wide range of sizes to accommodate diverse industrial needs:

| Parameter | Range |

|---|---|

| Outer Diameter (OD) | 1/8″ to 24″ (6.35 mm to 610 mm) |

| Wall Thickness | 0.5 mm to 50 mm |

| Length | 6 m to 12 m (custom lengths available) |

Common Schedules: SCH 10, SCH 40, SCH 80, SCH 160.

Applications of Low Temperature Seamless Pipes

Low Temperature Seamless Pipes are indispensable in industries requiring cryogenic resilience:

LNG Industry:

Liquefaction plants (-162°C).

LNG carrier ship pipelines.

Storage tank manifolds.

Petrochemical Plants:

Ethylene and propylene production (-104°C).

Cryogenic reactors and heat exchangers.

Air Separation Units (ASUs):

Liquid oxygen (-183°C) and nitrogen (-196°C) transport.

Aerospace:

Liquid hydrogen (-253°C) and helium systems.

Energy and Pharmaceuticals:

CO2 capture and medical gas storage.

Why Choose High-Quality Low Temperature Seamless Pipes?

Fracture Resistance: Charpy V-notch testing ensures ductility at sub-zero temps.

Corrosion Resistance: Nickel alloys and stainless steels prevent rust in moist cryogenic environments.

Pressure Integrity: Seamless construction avoids weak points in high-pressure systems.

Regulatory Compliance: Certified to ASTM, EN, and ASME standards.

Low temperature seamless pipes are engineered to meet the rigorous demands of cryogenic applications. By selecting materials like ASTM A333 Gr. 6 or Inconel 625, adhering to global standards (ASTM, EN, JIS), and choosing the right dimensions, industries ensure operational safety and efficiency in extreme cold.

For businesses seeking reliable low temperature seamless pipes, partnering with certified manufacturers guarantees compliance with international specifications. Explore Tianjin xiangliyuan steel‘s range of Low Temperature Seamless Pipes tailored for LNG, petrochemical, and aerospace applications.