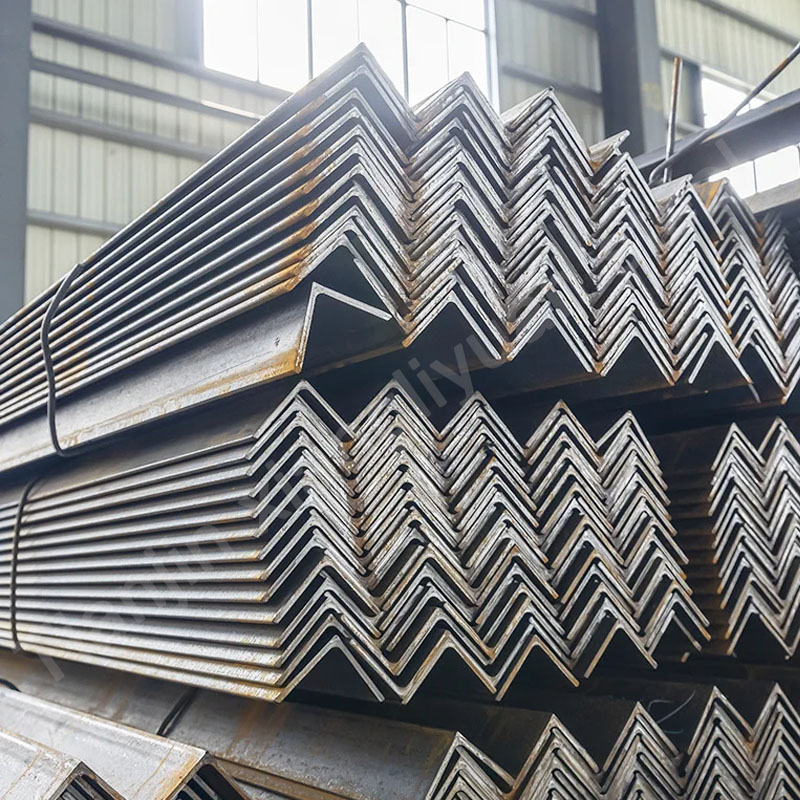

Angle steel, commonly known as angle iron or L-shaped steel, is a versatile structural steel profile characterized by its 90-degree right-angle cross-section. Comprising two legs (flanges) of equal or unequal lengths connected by a web, angle steel is widely used in construction, machinery, bridges, and industrial frameworks due to its exceptional load-bearing capacity, ease of fabrication, and cost-effectiveness. Whether reinforcing concrete structures, supporting equipment, or framing shelving systems, angle steel offers unmatched flexibility and strength.

This article explores the material grades, classifications, international standards, dimensional specifications, and applications of angle steel. Designed for engineers, architects, and procurement professionals, this guide will help you select the right angle steel for your project’s structural and functional requirements.

Key Materials and Steel Grades for Angle Steel

Angle steel is manufactured from various steel grades to meet strength, weldability, and environmental resistance needs. Below are the most common materials:

1. Carbon Steel Angles

ASTM A36 (USA): General-purpose carbon steel with 36 ksi yield strength, ideal for construction and machinery.

EN 10025 S235JR/S275JR (Europe): Non-alloy structural steel for low to medium stress applications.

JIS G3101 SS400 (Japan): Rolled steel with 400 MPa tensile strength for general structures.

GB/T 700 Q235B (China): Carbon structural steel with 235 MPa yield strength.

2. High-Strength Low-Alloy (HSLA) Steel

ASTM A572 Gr. 50: Offers 50 ksi yield strength for heavy-duty frameworks and bridges.

EN 10025 S355JR/S355J2: High-tensile steel for industrial and infrastructure projects.

3. Stainless Steel Angles

ASTM A276/AISI 304/316: Austenitic stainless steel for corrosive environments (e.g., marine, chemical plants).

EN 1.4301/1.4401: Equivalent to AISI 304/316 for European standards.

4. Galvanized Angle Steel

ASTM A653 (USA): Zinc-coated angles (G60, G90) for outdoor and high-moisture applications.

EN 10346 (Europe): Hot-dip galvanized steel with enhanced corrosion resistance.

Classification of Angle Steel

Angle steel is categorized based on leg dimensions, manufacturing processes, and application-specific designs:

1. By Leg Proportions

Equal Angle Steel: Both legs have the same length (e.g., 50×50 mm, 100×100 mm).

Unequal Angle Steel: Legs differ in length (e.g., 60×40 mm, 100×75 mm).

2. By Manufacturing Method

Hot-Rolled Angles: Produced by heating and shaping steel billets; cost-effective for heavy-duty use.

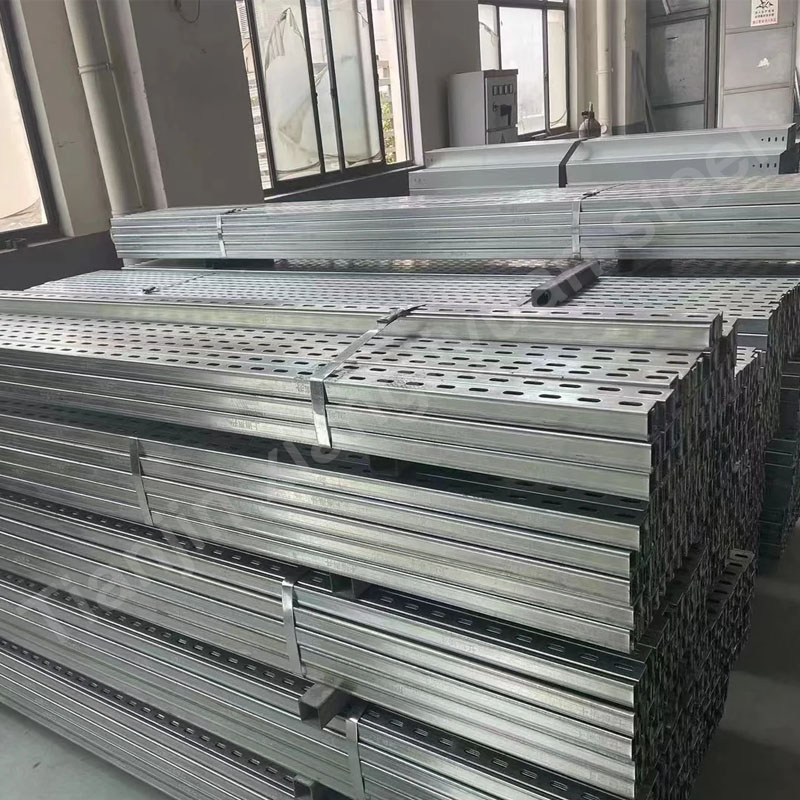

Cold-Formed Angles: Made by bending steel sheets at room temperature; precise dimensions for lightweight structures.

3. By Surface Treatment

Plain (Black) Angles: Uncoated steel for indoor or temporary use.

Galvanized Angles: Zinc-coated for rust resistance in outdoor settings.

Painted/Powder-Coated Angles: Aesthetic finishes for architectural projects.

International Standards for Angle Steel

Global standards ensure consistency in mechanical properties, tolerances, and dimensions:

| Standard | Region | Key Specifications |

|---|---|---|

| ASTM A36/A572 | USA | Carbon and HSLA steel angles for construction. |

| EN 10056-1 | Europe | Dimensions and tolerances for equal/unequal angles. |

| JIS G3192 | Japan | Hot-rolled steel angles (L-shaped profiles). |

| GB/T 706 | China | Technical requirements for hot-rolled angles. |

| AS/NZS 3679.1 | Australia | Structural steel angles for engineering. |

Standard Dimensions and Specifications

Angle steel is available in standardized sizes to suit diverse industrial needs:

Equal Angle Steel Sizes (Hot-Rolled)

| Designation | Leg Length (mm) | Thickness (mm) | Weight (kg/m) |

|---|---|---|---|

| 20x20x3 | 20×20 | 3 | 0.89 |

| 50x50x5 | 50×50 | 5 | 3.77 |

| 100x100x10 | 100×100 | 10 | 15.1 |

Unequal Angle Steel Sizes (Cold-Formed)

| Designation | Leg Length (mm) | Thickness (mm) | Weight (kg/m) |

|---|---|---|---|

| 60x40x4 | 60×40 | 4 | 2.42 |

| 80x50x6 | 80×50 | 6 | 4.47 |

| 120x80x8 | 120×80 | 8 | 11.9 |

Common Lengths: 6m, 8m, 10m, 12m (custom cuts available).

Applications of Angle Steel

Angle steel’s versatility makes it indispensable across industries:

Construction:

Reinforcing concrete columns, beams, and slabs.

Roof trusses, wall brackets, and stair stringers.

Manufacturing:

Machine frames, conveyor supports, and equipment bases.

Shelving systems, racks, and storage units.

Infrastructure:

Bridge girders, transmission towers, and highway guardrails.

Solar panel mounts and wind turbine frameworks.

Architecture:

Decorative façades, signage frames, and canopy structures.

Stainless steel angles for coastal and chemical-resistant designs.

How to Choose the Right Angle Steel

Load Requirements:

Use hot-rolled angles (e.g., ASTM A572) for heavy structural loads.

Opt for cold-formed angles (e.g., EN 10279) for lightweight applications.

Environmental Conditions:

Choose galvanized or stainless steel in corrosive or outdoor environments.

Compliance:

Ensure adherence to ASTM, EN, or JIS standards for certifications.

Why Opt for High-Quality Angle Steel?

Strength-to-Weight Ratio: Efficiently supports loads without excess bulk.

Corrosion Resistance: Galvanized or stainless options extend lifespan.

Ease of Fabrication: Simple to cut, weld, and bolt into complex assemblies.

Cost-Effectiveness: Reduces material waste and labor time.

Angle steel (angle iron) is a cornerstone of structural engineering, offering unmatched adaptability for construction, manufacturing, and architectural projects. By selecting the appropriate material grade (e.g., ASTM A36, EN S235JR), adhering to international standards, and understanding dimensional specifications, industries can optimize performance in applications ranging from skyscrapers to machinery bases.

For businesses seeking reliable angle steel, working with a certified supplier ensures compliance with global standards and a tailor-made solution. Explore Tianjin Xiangliyuan Steel’s range of hot-rolled, cold-formed and galvanized angle steel designed for durability and precision.