In the global energy infrastructure, pipeline systems play a vital role in transporting oil and gas efficiently and safely over long distances. At the heart of these systems lies the API 5L pipeline pipe, a product engineered to meet rigorous industry standards for durability, strength, and reliability. Whether for oil pipelines or gas pipelines, API 5L-certified pipes ensure seamless operations in demanding environments. This article dives deep into the specifications, classifications, international standards, and applications of API 5L pipes, providing a comprehensive guide for engineers, procurement professionals, and industry stakeholders.

What is API 5L Pipeline Pipe?

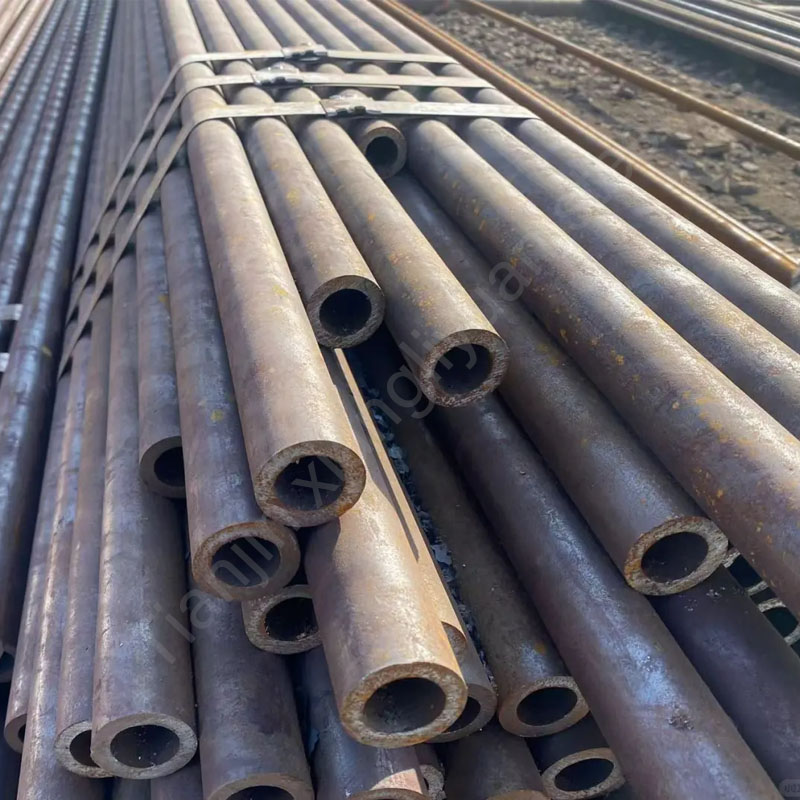

API 5L (American Petroleum Institute Specification 5L) is a globally recognized standard that specifies requirements for the manufacture of seamless and welded steel pipes used in the transportation of oil, gas, and water in the petroleum and natural gas industries. These pipes are designed to withstand high-pressure conditions, corrosive environments, and extreme temperatures, making them indispensable for onshore and offshore energy projects.

API 5L pipes are divided into two product specification levels (PSL):

PSL1: Standard quality pipes with basic chemical and mechanical requirements.

PSL2: Enhanced quality pipes with stricter controls on chemical composition, mechanical properties, and non-destructive testing (NDT).

Key Materials and Steel Grades

API 5L pipes are manufactured using carbon steel and low-alloy steel, with grades categorized by minimum yield strength. Below are the primary steel grades under the API 5L standard:

| Grade | Minimum Yield Strength (psi) | Common Applications |

|---|---|---|

| Gr A | 30,500 | Low-pressure water and gas pipelines |

| Gr B | 35,300 | Medium-pressure oil and gas systems |

| Gr X42 | 42,100 | High-pressure transmission pipelines |

| Gr X52 | 52,200 | Offshore and onshore gas pipelines |

| Gr X60 | 60,200 | Long-distance oil pipelines |

| Gr X65 | 65,300 | Subsea and sour service pipelines |

| Gr X70 | 70,300 | Arctic and high-stress environments |

| Gr X80 | 80,500 | Ultra-high-pressure gas pipelines |

Higher-grade steels (e.g., X70, X80) are increasingly used for modern pipelines to reduce wall thickness, lower material costs, and improve transportation efficiency.

Classification: Seamless vs. Welded API 5L Pipes

API 5L pipes are classified based on manufacturing processes:

Seamless Pipes

Produced by extruding steel billets without welding.

Ideal for high-pressure applications (e.g., oil pipelines, gas pipelines).

Common sizes: 1/2″ to 24″ OD (outer diameter), wall thickness from SCH 40 to SCH 160.

Welded Pipes

Fabricated by rolling steel plates/sheets and welding the seam.

Subtypes include Longitudinal Submerged Arc Welded (LSAW), Spiral Welded (SSAW), and Electric Resistance Welded (ERW).

Cost-effective for large-diameter projects (up to 48″ OD).

Global Standards and Equivalent Specifications

While API 5L is the primary standard for oil and gas pipelines, many countries adopt equivalent or supplementary standards:

ISO 3183: International standard aligning with API 5L for line pipe applications.

EN 10208 (Europe): Covers steel pipes for combustible fluids, with grades like L245 (equivalent to Gr B) and L485 (X70).

GB/T 9711 (China): Similar to API 5L but includes additional testing requirements.

GOST 20295 (Russia): Specifies pipes for oil and gas transport, compatible with API 5L grades.

Engineers must ensure compliance with local regulations, such as ASME B31.4 (liquid pipelines) and ASME B31.8 (gas pipelines) in the U.S.

Standard Dimensions and Specifications

API 5L pipes are available in a wide range of sizes to suit diverse project requirements:

| Parameter | Range |

|---|---|

| Outer Diameter (OD) | 0.5″ to 48″ (12.7 mm to 1,219 mm) |

| Wall Thickness | 0.5 mm to 50 mm (varies by grade and OD) |

| Length | Single random (5-7m), double random (11-13m), or custom lengths |

Common specifications include:

Schedule 40: Standard wall thickness for moderate pressure.

Schedule 80: Heavy wall for high-pressure oil pipelines.

API 5L X65 SSAW: Spiral-welded pipes for large-diameter gas pipelines.

Applications in Oil and Gas Pipelines

API 5L pipes are the backbone of energy transportation networks. Key applications include:

Oil Pipelines

Transport crude oil from extraction sites to refineries.

High-grade steels (X60-X80) resist internal corrosion caused by sulfur and hydrocarbons.

Gas Pipelines

Distribute natural gas overland and subsea.

PSL2 pipes with Charpy V-notch testing ensure fracture resistance in cold climates.

Water Injection Lines

Used in offshore oil fields to maintain reservoir pressure.

CO2 Transport

Special coatings combat corrosion in carbon capture pipelines.

Advantages of API 5L Pipeline Pipes

High Strength-to-Weight Ratio: Enables cost-effective, long-distance installations.

Corrosion Resistance: Options include 3LPE coating, FBE epoxy, or galvanization.

Compliance: Meets HSE (health, safety, environment) regulations worldwide.

Choosing the Right API 5L Pipe Supplier

When sourcing API 5L pipes, prioritize suppliers who:

Provide mill test certificates (MTC) for traceability.

Offer anti-corrosion coatings tailored to project needs.

Adhere to ISO 9001, API Monogram, and PED certifications.

API 5L pipeline pipes are critical to the safe and efficient operation of oil pipelines, gas pipelines, and other fluid transportation systems. By understanding the material grades, manufacturing processes, and global standards, industry professionals can select pipes that deliver optimal performance and longevity. As energy demands grow, API 5L-certified pipes will remain indispensable in building resilient infrastructure for the future.