In the world of solar energy, much attention is rightly given to the photovoltaic panels themselves—the marvels of technology that convert sunlight directly into electricity. However, even the most advanced solar panel is only as good as the structure that holds it. This is where the critical, yet often overlooked, component comes into play: the photovoltaic purlin.

As a leading manufacturer in the solar mounting industry, we understand that the integrity, longevity, and overall performance of a solar power plant hinge on the quality of its mounting system. Purlins form the essential skeleton of this system, providing the sturdy, reliable foundation upon which entire arrays are built. This in-depth guide will explore everything you need to know about PV purlins, from their material composition to their decisive role in the success of your solar project.

What is a PV Purlin?

A purlin in photovoltaic mounting systems is a horizontal beam or bar that serves as the primary support structure for the solar panels. It is mounted perpendicular to the main rafters or trusses of a structure (in rooftop installations) or onto the main posts and beams (in ground-mounted systems). The solar panels are then secured directly onto these purlins using specialized clamps.

Think of the mounting system as a table: if the main rails are the legs, the purlins are the tabletop’s supporting frame. They bear the constant weight of the panels and must withstand decades of environmental stress, including high winds, heavy snow loads, and seismic activity. Their design, material, and protection are therefore paramount.

Material Composition: The Foundation of Strength and Durability

The choice of material for PV purlins is a fundamental decision that impacts the system’s cost, weight, structural capacity, and corrosion resistance. The two primary materials used are:

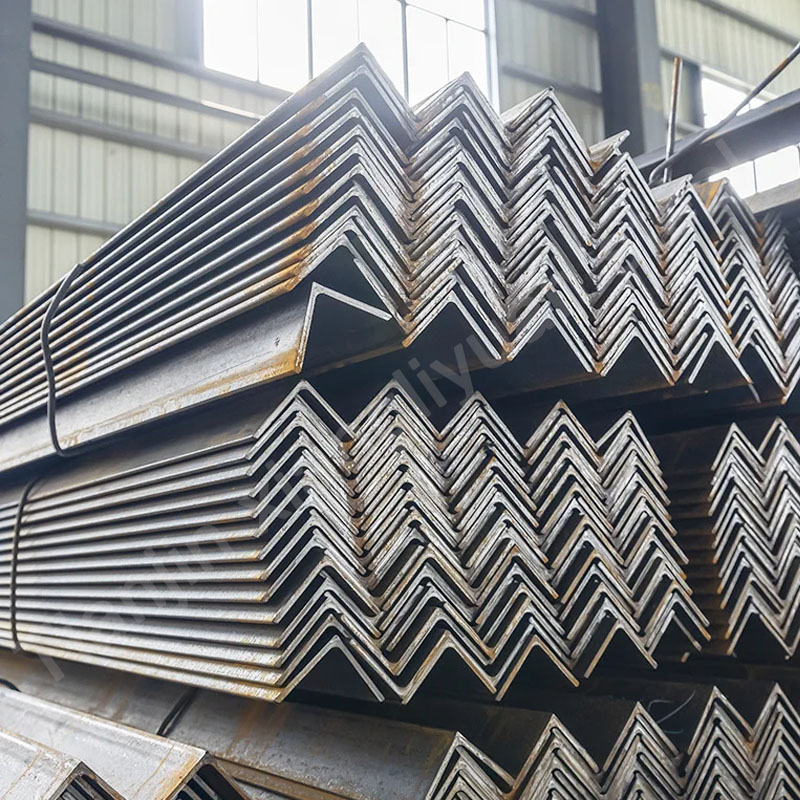

1. Carbon Steel (Q235, Q355, S235JR, S355JR, ASTM A36, A572)

Carbon steel is the most widely used material for solar purlins due to its exceptional strength-to-cost ratio.

High Strength: Grades like Q355 (equivalent to S355JR/A572) offer high yield strength, allowing for longer spans between supports and the ability to handle heavier snow and wind loads. This can reduce the overall number of supports needed, lowering installation time and material costs.

Durability: While susceptible to corrosion if untreated, when combined with advanced surface treatments like hot-dip galvanizing (HDG), carbon steel provides decades of reliable service.

Formability: Steel is easily cold-rolled into a variety of complex cross-sectional shapes (C-section, Z-section, U-section) that optimize structural performance.

2. Aluminum Alloy (6061-T6, 6005-T5)

Aluminum is a popular alternative, especially in corrosive environments or where weight is a significant concern.

Natural Corrosion Resistance: Aluminum forms a protective oxide layer on its surface, making it highly resistant to atmospheric corrosion. This is a key advantage for installations near coastlines or in areas with high industrial pollution.

Lightweight: Aluminum purlins are approximately one-third the weight of steel, making them easier to handle, transport, and install. This can be a critical factor for rooftop projects where adding excessive weight to the building structure is a concern.

Strength: While not as strong as carbon steel pound-for-pound, alloys like 6061-T6 and 6005-T5 offer sufficient mechanical properties for most solar applications. Their design often requires slightly different profiles to achieve comparable load-bearing capacity.

Material Selection Guide:

Choose Carbon Steel for most utility-scale ground-mounted and commercial rooftop projects where ultimate strength and cost-efficiency are the primary drivers.

Choose Aluminum Alloy for coastal applications, chemical plants, or lightweight rooftop systems where the structure’s weight limit is a constraint.

Surface Treatment: Shielding Against the Elements

A PV mounting system is exposed to the elements 24/7 for 25 years or more. Without robust protection, even the strongest steel will succumb to rust. Surface treatment is not an option; it is a necessity.

1. Hot-Dip Galvanizing (HDG) – The Industry Standard for Steel

This is the most common and effective corrosion protection method for steel purlins. The process involves:

Cleaning: The steel is dipped in a series of cleaning solutions to remove grease, dirt, and mill scale.

Fluxing: It is then dipped in a flux solution to prevent oxidation before galvanizing.

Galvanizing: The clean steel is immersed in a bath of molten zinc at around 450°C (840°F).

Reaction & Cooling: A metallurgical bond forms between the zinc and the steel, creating a series of zinc-iron alloy layers topped by a layer of pure zinc. The purlin is then cooled.

Advantages of HDG:

Complete Coverage: The dipping process coats both the exterior and interior surfaces, including hard-to-reach corners.

Cathodic Protection: The zinc sacrificially protects the underlying steel. Even if the coating is scratched, the zinc will corrode first, preventing rust from forming on the steel.

Long Service Life: A typical HDG coating of 80-100 microns (µm) can provide corrosion protection for 25-50 years, depending on the environment (C2 to C5 classes).

2. Aluminum Alloy: Anodizing or Powder Coating

While aluminum is naturally corrosion-resistant, additional surface treatments are often applied for enhanced durability or aesthetics.

Anodizing: An electrochemical process that thickens the natural oxide layer, increasing hardness and wear resistance.

Powder Coating: A dry powder is electrostatically applied to the aluminum and then cured under heat to form a hard, protective, and decorative layer. It offers a wide range of colors for aesthetic blending.

Dimensions, Specifications, and Wall Thickness

PV purlins are not one-size-fits-all. Their dimensions must be meticulously engineered to meet the specific load requirements of each project. Key specifications include:

-

Profile Type: The most common profiles are C-section and Z-section. Z-purlins are often preferred for their high strength-to-weight ratio and ability to be overlapped at supports for continuous beam performance.

-

Dimensions: Common sizes range from 40mm to 120mm in height and 40mm to 80mm in flange width. The exact size is determined by structural engineering calculations based on span, spacing, and local climatic loads.

-

Wall Thickness: This is a critical factor for strength. Thicknesses typically range from 1.5mm to 3.0mm. Thicker walls (e.g., 2.5mm – 3.0mm) are used for heavy-load applications, longer spans, or in high-wind/snow regions. Thinner walls (1.5mm – 2.0mm) are suitable for less demanding applications and help reduce material costs and weight.

-

Length: Purlins can be supplied in standard lengths (e.g., 3m to 8m) or custom-cut to the exact project requirements to minimize on-site cutting and waste.

Engineering Matters: It is crucial to work with suppliers who provide full technical data and support. The purlin design must comply with international standards (e.g., ISO, ASTM, EN) and be certified by professional engineers to ensure the entire array’s safety and performance.

Application Domains: Where Purlins Prove Their Worth

PV purlins are versatile components used across the entire solar industry:

-

Utility-Scale Ground-Mount Power Plants: This is the most demanding application, requiring extremely robust purlins with high load capacities to cover vast areas efficiently.

-

Commercial & Industrial (C&I) Rooftops: Purlins are used to create a raised framework that secures panels to the roof structure without penetrating the roofing membrane (in ballasted systems) or integrates with penetrating anchors.

-

Agricultural & Carport Structures: Solar carports and agricultural solar setups rely on long, strong purlins to create the canopy structure that supports the panels overhead.

-

Residential Rooftops: While sometimes using different mounting rails, many modern residential systems also utilize purlin-style designs for their strength and adaptability.

Product Features and Design Innovations

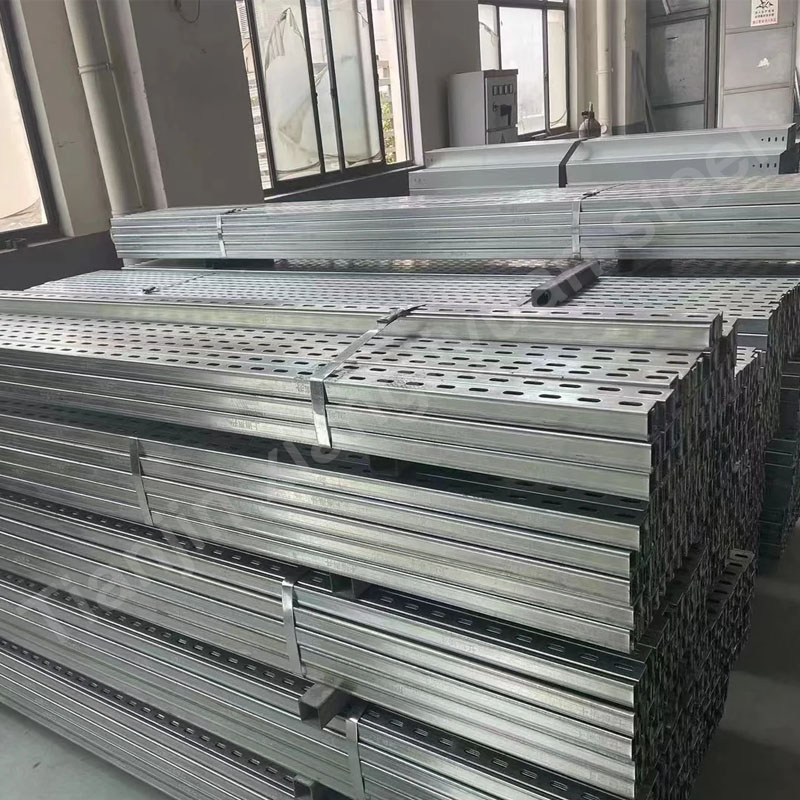

Modern PV purlins are engineered with precision and intelligence. Key features include:Pre-Punched Holes: Precision laser-cut or punched mounting holes at regular intervals allow for fast, easy, and accurate installation of panel clamps and mid-connectors, drastically reducing labor time.

High-Strength Design: Optimized cross-sectional shapes provide maximum stiffness and load-bearing capacity with minimal material usage, contributing to a lower overall system cost.

Compatibility: Designed to be universally compatible with a wide range of solar panels and branded mounting components (clamps, end-clamps, mid-connectors).

Ease of Installation: Lightweight yet rigid designs and pre-punched features make them easy for installers to handle and secure quickly.

The Unbeatable Advantages of High-Quality Purlins

Investing in premium purlins from a reputable manufacturer delivers tangible benefits throughout the project lifecycle:Exceptional Durability and Longevity: A high-quality, hot-dip galvanized steel purlin ensures your solar investment is protected for its entire operational lifespan, minimizing maintenance and replacement costs.

Superior Structural Integrity: Engineered to meet strict international building codes, they provide peace of mind that the array will withstand extreme weather events, protecting both the asset and the surrounding environment.

Cost-Effectiveness: By optimizing material use and enabling faster installation, a well-designed purlin system significantly reduces the Balance of System (BOS) costs, which is crucial for the project’s overall financial viability.

Installation Efficiency: Pre-engineered components with precise hole patterns streamline the installation process, reducing labor hours, on-site errors, and overall project timelines.

Project Flexibility: Available in a wide range of sizes and strengths, they can be tailored to suit any project size and any geographical location, from a sun-drenched desert to a snow-prone mountainous region.

Sustainability: Steel is one of the world’s most recyclable materials. At the end of its long life, a steel purlin can be completely recycled, contributing to the circular economy and enhancing the green credentials of the solar project.

The Bedrock of a Successful Solar Project

Choosing the right PV purlin is a strategic decision that directly impacts the safety, performance, and return on investment of a solar power system. It is the unseen hero that works silently for decades, ensuring that the panels remain perfectly positioned to harvest the sun’s energy.As a manufacturer dedicated to excellence, Tianjin xiangliyuan steel produce purlins that are not just metal bars, but precision-engineered components. From sourcing the highest-grade raw materials to applying rigorous quality control throughout our hot-dip galvanizing and fabrication processes, we ensure every purlin that leaves our facility is built to last.