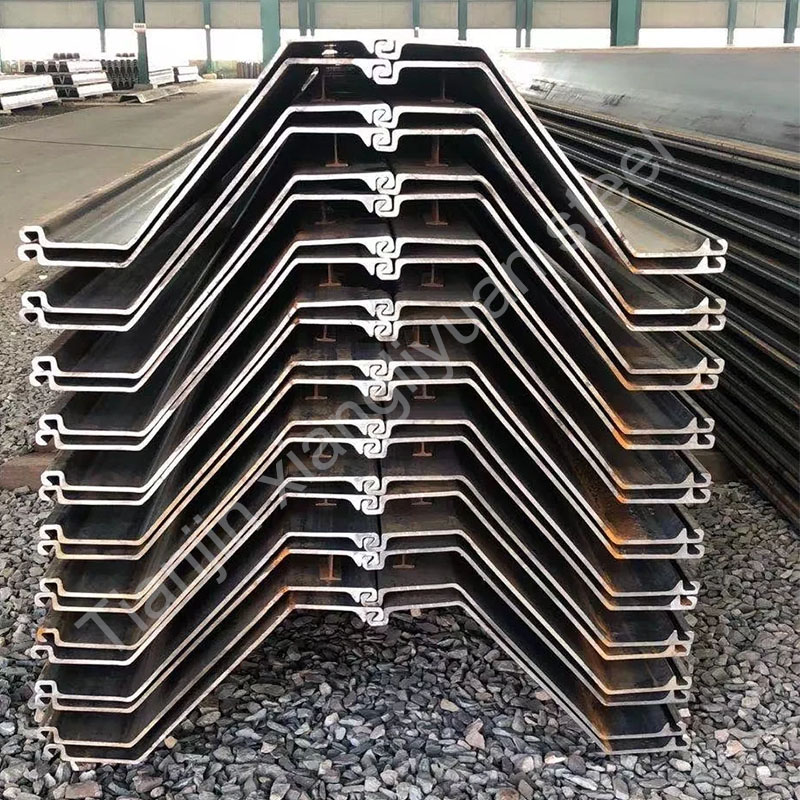

What is a Z-shaped steel sheet pile?

Z-shaped steel sheet pile is a common type of steel sheet pile. Its cross-sectional shape is similar to the letter “Z” and is connected to each other by locks to form a continuous wall. Its design features make the central axis of each steel sheet pile relatively offset, so that a continuous retaining structure can be formed when assembled. Z-shaped steel sheet piles are widely used in infrastructure construction and civil engineering.

I. Material

The material of Z-shaped steel sheet piles is generally **carbon structural steel** or **low-alloy high-strength structural steel**. Commonly used steels are as follows:

1. Q235B: Excellent comprehensive performance, moderate strength, suitable for ordinary engineering.

2. Q345B: High yield strength, suitable for occasions with high strength requirements.

3. S355/S390/S430: These are high-strength steels that meet European EN standards and have better durability and tensile properties.

4. ASTM A572 Grade 50: American standard steel, commonly used in international engineering projects.

The choice of material is mainly based on engineering requirements, environmental conditions (such as corrosive environment) and budget.

II. Implementation standards

The production and quality control of Z-shaped steel sheet piles generally follow the following international and national standards:

1. Chinese standards:

– GB/T 20933-2007 “Hot-rolled steel sheet piles”

2. European standards:

– EN 10248-1/2: Technical delivery conditions and geometric parameters of hot-rolled steel sheet piles.

3. Japanese standards:

– JIS A 5523: Hot-rolled steel sheet piles.

4. American standards:

– ASTM A6: General technical specifications for steel sheet piles.

Different standards have different focuses, but all have strict requirements on the mechanical properties, dimensional tolerances and appearance quality of sheet piles.

III. Common specifications and sizes

The specifications of Z-shaped steel sheet piles are divided according to width, height and thickness. The following are some common specifications:

1. Width (b): Usually between 400mm and 800mm.

2. Height (h): Generally between 150mm and 400mm, affecting the bearing capacity of the pile.

3. Thickness (t): The thickness of the sheet body is usually 6mm to 16mm.

4. Length (L): The length can be customized according to the needs of the project, and the common range is 6m to 25m.

Example specifications:

– Z22 (width 770mm, height 220mm, thickness 8mm).

– Z36 (width 675mm, height 360mm, thickness 13mm).

In addition, the Z-shaped steel sheet pile is equipped with **locking grooves** on both sides, and the locking structure ensures good airtightness between the sheet piles.

IV. Shape and design

The design features of the Z-shaped steel sheet pile are as follows:

1. Asymmetric Z-shaped section: effectively disperse the load and increase the overall rigidity of the retaining wall.

2. High section modulus: Compared with U-shaped or straight sheet steel sheet piles, Z-shaped steel sheet piles have a higher section modulus and better bending resistance.

3. Lock design: The locks at both ends can be flexibly connected to ensure water tightness and strength after installation.

V. Uses

Z-shaped steel sheet piles are widely used in the following engineering fields:

1. Port and dock engineering: used to build breakwaters, dock walls, revetment structures, etc.

2. Foundation pit support: used to support foundation pit slopes at construction sites to prevent collapse.

3. Flood control and water conservancy projects: used for dam construction, river management and flood control wall structures.

4. Bridge construction: used for retaining or cofferdam construction in pier foundations.

5. Soil and water pollution control: used to build underground barriers to prevent pollution from spreading.

Z-shaped steel sheet piles are particularly suitable for projects that require high strength, high bending stiffness and continuous retaining structures.

VI. Features

1. Advantages:

– High strength and durability: Z-shaped steel sheet piles have a high bearing capacity and can adapt to complex geological conditions.

– Convenient construction: Through mechanical piling, the construction speed is fast and the adaptability is strong.

– Tight connection: The lock structure ensures the water tightness between the sheet piles and can effectively prevent water seepage.

– Reusable: Suitable for temporary projects and can be recycled after disassembly.

2. Disadvantages:

– High equipment requirements: Professional vibrating hammer or hydraulic equipment is required for installation.

– Large initial investment: Although it can be reused, the cost of a single steel sheet pile is relatively high.

Z-shaped steel sheet piles have played an important role in port terminals, water conservancy projects, construction foundation pits and other fields due to their superior structural performance and versatility. Its high strength, easy installation and good environmental adaptability make it an important choice in modern engineering. When purchasing and using, the appropriate material, specification and standard should be selected according to the project requirements, and the rationality of the construction method should be paid attention to in order to give full play to its advantages.