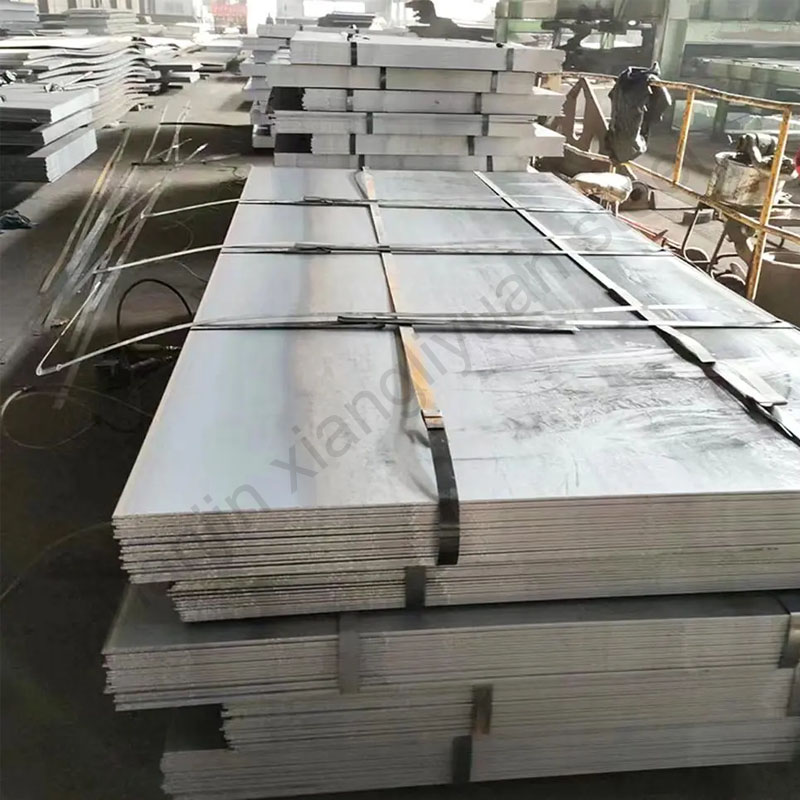

Carbon steel plate is a widely used steel in the steel industry. It is characterized by high strength, good toughness and good processing performance, and is suitable for a variety of engineering and manufacturing fields.

1. Main classification of carbon steel plates

1. Ordinary carbon steel plate

Ordinary carbon steel plate is the most widely used type of carbon steel plate. It has excellent strength and plasticity, can be cold and hot processed, and is widely used in construction, bridges, vehicles, boilers and other fields. It has low production cost and moderate performance, and is a general-purpose steel.

2. Weathering steel plate

Weathering steel plate is favored for its superior corrosion resistance. By adding a small amount of alloy elements (such as copper, chromium, nickel, etc.) to the steel, a dense oxide film layer is formed, thereby delaying the rust process. Weathering steel plates are widely used in bridges, building exterior walls, garden sculptures and other occasions that need to be exposed to the natural environment for a long time.

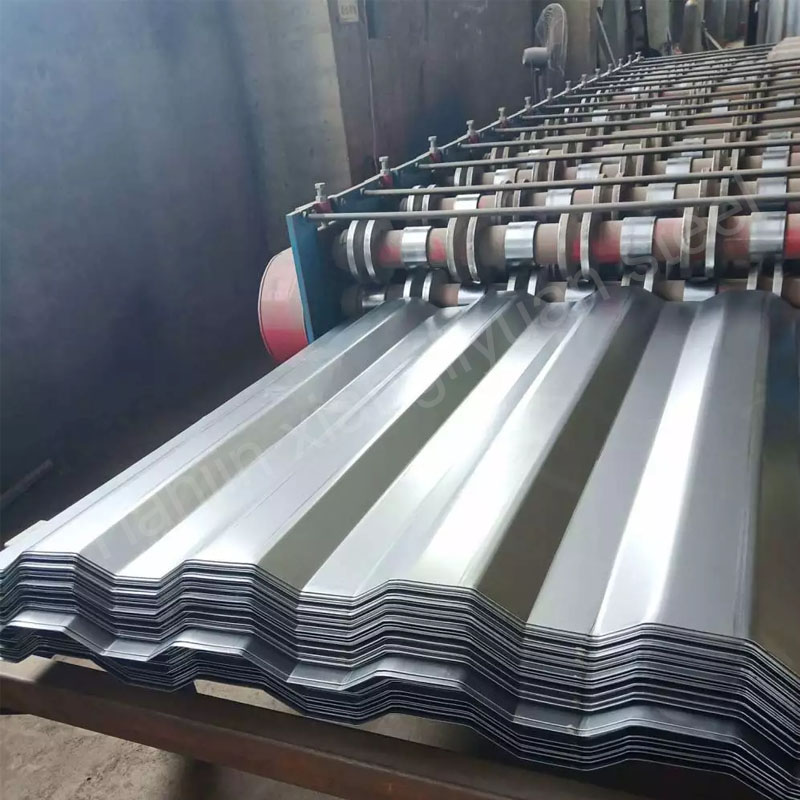

3. Patterned steel plate

Patterned steel plate is a steel plate with a raised pattern on the surface, mainly used in the field of ground, anti-slip equipment and decoration. Common patterns include diamond, lentil, round bean, etc., which are not only beautiful and practical, but also can effectively prevent slipping and waterproof.

4. Wear-resistant steel plate

Wear-resistant steel plate is a special steel plate with high hardness and high wear resistance, suitable for high wear environments such as mining machinery, engineering machinery, and loader buckets. Its wear resistance comes from the alloy coating with high surface hardness or the substrate with special heat treatment.

2. Main materials of carbon steel plate

The materials of carbon steel plate mainly include the following:

1. Low carbon steel (Q235, A36, etc.)

The carbon content of low carbon steel is generally less than 0.25%, with good plasticity and weldability. Commonly used in construction, machinery manufacturing and other fields.

2. Medium carbon steel (Q345, A572, etc.)

The carbon content of medium carbon steel is between 0.25%-0.6%, with high strength and hardness. Suitable for structural parts that need to bear higher loads.

3. High carbon steel

The carbon content of high carbon steel is above 0.6%. It has high strength but low plasticity and toughness. It is mostly used to make knives, springs and wear-resistant parts.

4. Alloy steel

In order to improve the performance of carbon steel, elements such as manganese, silicon, molybdenum, and vanadium can be added to carbon steel. Alloy steel plates such as 16Mn, NM360, NM400, etc. are widely used in industrial manufacturing.

3. Main standards for carbon steel plates

In the production and application of carbon steel plates, different countries and regions have formulated a variety of standards. The following is an introduction to the main standards:

1. Chinese standard (GB standard)

– GB/T 700: “Carbon structural steel”

– GB/T 3274: “Hot-rolled steel plates and strips”

– GB/T 4171: “Weathering structural steel”

– GB/T 24186: “Wear-resistant steel plate”

2. American standard (ASTM standard)

– ASTM A36: “Carbon structural steel”

– ASTM A588: “High-strength low-alloy weathering steel”

– ASTM A516: “Carbon steel plate for pressure vessels”

3. European standard (EN standard)

– EN 10025-2: “Non-alloy structural steel”

– EN 10155: “Weathering structural steel”

4. Japanese standard (JIS standard)

– JIS G3101: Carbon steel for general structures

– JIS G3125: Weathering steel

These standards have clear provisions on the chemical composition, mechanical properties and production process of steel plates, and users can choose suitable products according to specific needs.

4. Practical application of carbon steel plates

In practical applications, carbon steel plates have become an irreplaceable and important material due to their diverse performance.

– Ordinary carbon steel plates are mainly used in building infrastructure, such as building structures, bridges and railway tracks.

– Weathering steel plates are widely used in outdoor facilities, garden buildings and transportation facilities due to their superior corrosion resistance.

– Patterned steel plates are commonly seen in carriage floors, stair treads and decorative walls, which not only enhances the aesthetics but also takes into account practicality.

– Wear-resistant steel plates are the “main force” in the industrial field and are used in high-wear environments such as mining machinery and loader buckets.

Whether it is ordinary carbon steel plates, weathering steel plates, patterned steel plates or wear-resistant steel plates, they play an irreplaceable role in their respective fields and provide solid material guarantees for industrial and social construction.