Scaffolding tubes are a type of temporary structural material commonly used in construction. They are mainly used to build scaffolding to provide a stable platform and safety guarantee for workers when working at heights. They are characterized by high strength, good durability, and easy installation. They are widely used in construction, bridge construction, maintenance, and other fields.

Material

Scaffolding tubes are usually made of the following materials:

1. Carbon steel: One of the most commonly used materials, with high strength and durability, suitable for most construction environments.

2. Alloy steel: Used for special projects with high requirements for strength and corrosion resistance.

3. Galvanized steel: The surface is coated with a zinc layer, which has excellent anti-corrosion properties and is suitable for humid or highly corrosive environments, such as construction projects in coastal areas.

Common steel grades include Q195, Q235, and Q345, among which Q235 steel is the most common choice in the construction industry because of its good strength and ductility.

Standards

The manufacture and use of scaffolding tubes need to comply with relevant national or industry standards to ensure their safety and reliability. The following are common scaffolding pipe standards:

1. Chinese National Standard (GB Standard):

– GB/T 3091: Welded steel pipe for low-pressure fluid transportation, applicable to ordinary scaffolding pipes.

– GB/T 13793: Standard for straight seam electric welded steel pipes.

– GB/T 700: Standard for carbon structural steel, applicable to the material requirements of scaffolding pipes.

2. International Standards:

– EN 39 (European Standard): specifies the dimensions, materials and mechanical properties of scaffolding pipes.

– BS 1139 (British Standard): Applicable to scaffolding accessories and systems.

– ASTM A53 (American Standard): Applicable to welded and galvanized scaffolding pipes.

The standard usually specifies the diameter, wall thickness, length, tolerance, mechanical properties and other parameters of the scaffolding pipe. For example, the outer diameter of the commonly used scaffolding pipe in the Chinese standard is 48.3mm, and the wall thickness is between 2.75mm and 3.25mm.

Classification

According to the processing technology and function, scaffolding pipes can be divided into the following categories:

1. Classification by material:

– Black pipe: ordinary steel pipe that has not been galvanized, with a lower price but weaker anti-corrosion ability.

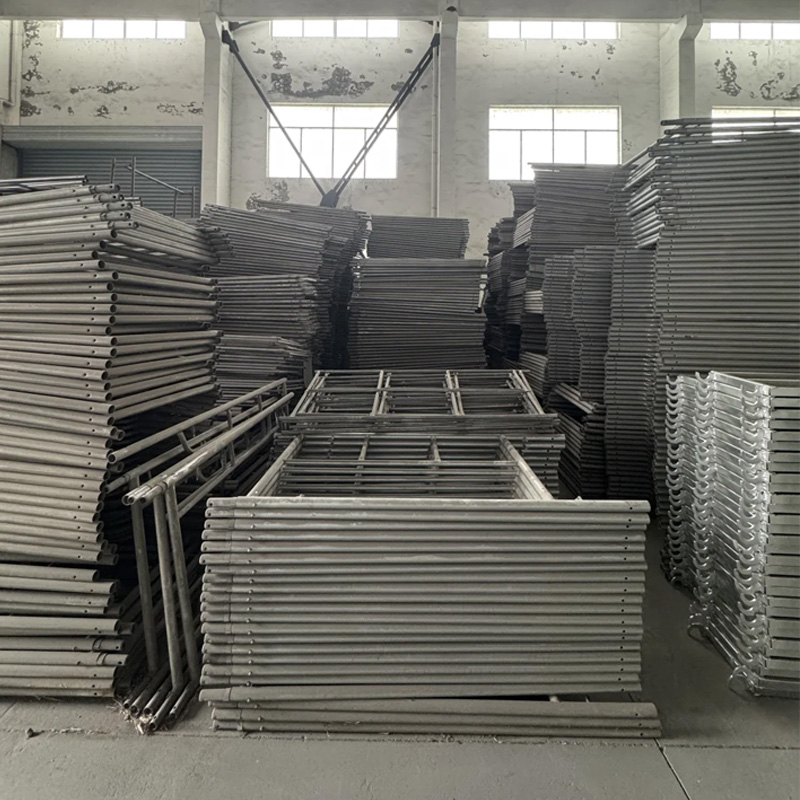

– Galvanized pipe: After hot-dip galvanizing, it has stronger anti-corrosion performance and is suitable for long-term or high-corrosion environments.

2. Classification by connection method:

– Fastener scaffolding pipe: The steel pipe is connected by fasteners, which is flexible and suitable for various complex construction environments.

– Socket-type scaffolding pipe: connected by plug-in method, easy to install and high stability.

– Scaffolding system pipe: such as bowl buckle, wheel buckle and door scaffolding, which has structural and systematic characteristics.

3. Classification by use:

– Support pipe: used to bear construction loads.

– Crossbar pipe: mainly used as a horizontal connector to improve the integrity of the structure.

Use

Scaffolding pipes have a wide range of uses, including but not limited to the following aspects:

1. Construction: used to build external scaffolding or internal support for building construction.

2. Bridge construction: Build a bridge construction platform to provide convenience for high-altitude operations.

3. Repair and maintenance: Suitable for cleaning, decoration or repair of building exterior walls.

4. Industrial field: Build support platforms in large-scale projects such as shipbuilding and petrochemicals.

5. Activity venues: Used to temporarily build stage and auditorium support structures.

Advantages

The advantages of scaffolding pipes include the following aspects:

1. High strength and strong bearing capacity: Scaffolding pipes are made of high-quality steel and can withstand large construction loads to ensure construction safety.

2. Flexible structure and strong adaptability: Scaffolding pipes can adjust height and structural form according to different construction requirements to adapt to complex environments.

3. Excellent anti-corrosion performance: Especially galvanized scaffolding pipes, which can resist corrosion for a long time and extend service life.

4. Reusable, economical and practical: Scaffolding pipes can be disassembled and reused many times, greatly reducing construction costs.

5. Convenient construction: The pipes are light and the connection method is simple, which can be quickly built and disassembled, saving work time.

6. Standardized production: The dimensions and specifications are strictly manufactured in accordance with the standards, which is convenient for construction management and on-site adjustment.

Scaffolding pipes are indispensable materials in modern construction. Their material selection, manufacturing standards, classification methods, etc. determine their applicability in different scenarios. With the advantages of high strength, flexibility and economy, scaffolding pipes are widely used in various engineering projects, providing a strong guarantee for construction safety and efficiency. In the future, with the advancement of construction technology and the research and development of new materials, scaffolding pipes will also develop in a more lightweight, efficient and environmentally friendly direction.