Petroleum Oil cracking tubes are seamless tubes for furnace tubes, heat exchanger tubes and pipelines in oil refineries. In the process of oil refining, they are mainly used in cracking units. Cracking is a chemical process that breaks down long-chain hydrocarbon molecules into shorter molecules by heating or pressurizing to produce light oil products such as gasoline and diesel. Cracking pipes need to work under high temperature, high pressure and corrosive environment, so the requirements for materials are very high.

Commonly used high-quality carbon steel (10, 20), alloy steel (12CrMo, 15CrMo), heat-resistant steel (12Cr2Mo, 15Cr5Mo), stainless steel (1Cr18Ni9, 1Cr18Ni9Ti) manufacturing.

According to the manufacturing process and materials, Petroleum Oil cracking pipes can be divided into the following categories:

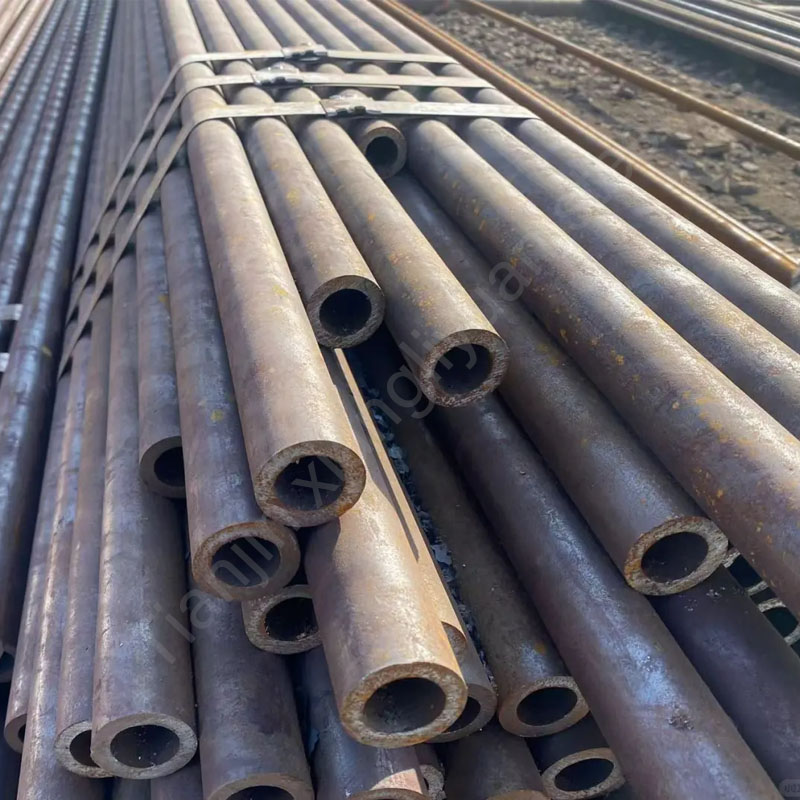

Seamless steel pipes: manufactured by hot rolling, cold drawing and cold rolling processes, with high strength and corrosion resistance.

Welded steel pipes: manufactured by welding process, the cost is low, but in high temperature and high pressure environment, the welding point is easy to become a weak point.

Alloy steel pipe: alloy elements are added to improve high temperature resistance and corrosion resistance, and are often used in more demanding working environments.

Stainless steel pipe: has excellent corrosion resistance and is suitable for environments containing corrosive media such as acids and alkalis.

The manufacture and use of petroleum cracking pipes need to follow a series of national and international standards:

Chinese standards:

GB/T 9948-2013 “Seamless steel pipes for petroleum cracking”

GB/T 24590-2009 “High temperature alloy seamless steel pipes for petroleum cracking units”

International standards:

ASTM A335 “Seamless ferritic alloy steel pipes for high temperature”

ASTM A213 “Seamless ferritic and austenitic alloy steel pipes for boilers, superheaters and heat exchangers”, etc.

Petroleum cracking pipes are mainly used in the following fields:

Petrochemical units: used in key equipment such as cracking furnaces, heating furnaces, reactors, etc.

Refineries: used in various cracking units and pipeline systems.

Natural gas processing: transport and process natural gas under high temperature and high pressure.

Other chemical industries: suitable for chemical processes that require high temperature, high pressure and corrosion resistance.

Other uses: Using petroleum cracking tubes to make annular parts can improve material utilization, simplify manufacturing processes, save materials and processing time, such as rolling bearing rings, jack sleeves, etc., which are now widely made of steel pipes. Petroleum cracking tubes are also indispensable materials for various conventional weapons. Gun barrels and cannon barrels are all made of petroleum cracking tubes.