The advanced grouting small catheter is a technique used in tunnel excavation construction. For the sections that are about to be excavated but have not yet been excavated, the construction technology is to support first and then excavate. The main purpose is to prevent collapse during the excavation process because the surrounding rock grade is low. This is where the word “advanced” comes from. “Small catheter” literally means a seamless tube, and the catheter must be used to introduce something. What is imported is reinforced concrete.

During tunnel construction, the broken and weak bottom layer is prone to collapse holes, structural sections, and difficulties in advanced anchor construction after being hollowed out. At this time, The advanced grouting small catheter can be used for support. If conditions permit, it can be carried out. The advanced small duct on the ground is fixed. If there is a pilot tunnel, radial grouting around the tunnel can also be carried out in the pilot tunnel.

The small catheter grouting technology is simple to construct, has simple tools, and has a small construction space. Moreover, when encountering changes in the underlying layer, the construction plan can be adjusted according to the actual situation. The advanced grouting small catheter has strong applicability and can be used in construction. , can save costs very well, therefore, it has been widely used in tunnel construction.

Usually, the processing range of the advanced small catheter is about 6 meters, its wall thickness is about 5 mm, and the diameter is usually 42 mm. It is a very good method to consolidate the relatively broken surrounding rock through small catheter, so that the surrounding rock can form a whole, and then the next construction step can be carried out smoothly.

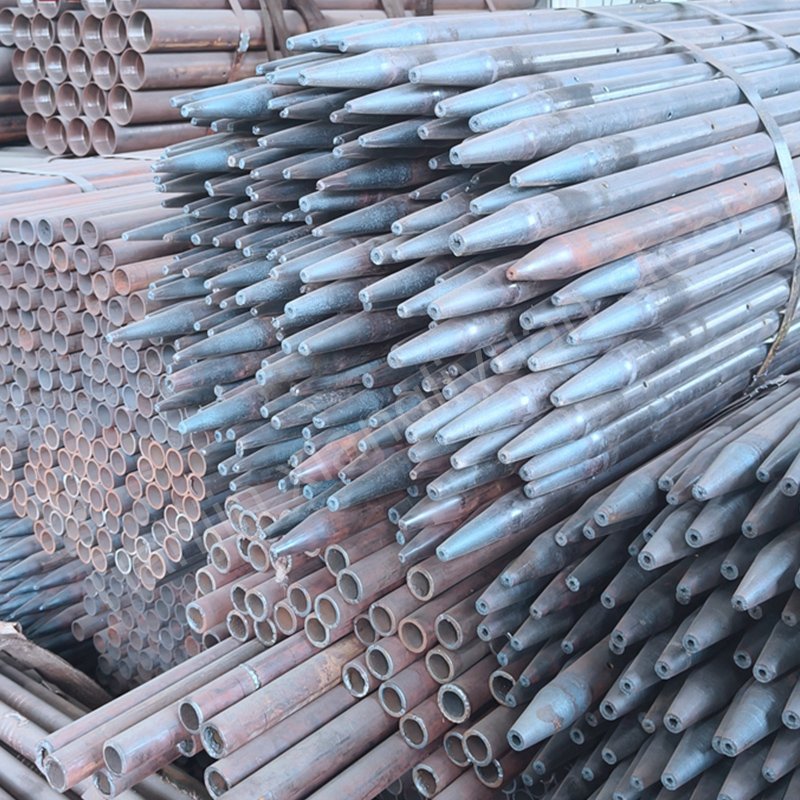

The picture above is what the advanced small catheter looks like. Carefully, the head of the pipe is pointed and there are holes on the wall of the pipe. As a workpiece for advance support, the small advance duct needs to be drilled in advance in the section to be excavated and then the small advance duct is inserted into the drilled hole. The sharp tip in front ensures smooth penetration into the hole. Concrete is then injected into the back end of the small conduit. After the concrete reaches the pipe and is filled, part of it will overflow through the holes in the pipe wall and flow to the gaps in the rock. After the concrete solidifies, it achieves the effect of hardening and strengthening.

Specifications of The advanced grouting small catheter

Pipe diameter size: 42mm, 50mm, 76mm or 108mm seamless steel pipe (common pipes with diameters of 42 and 50 are more common, and a small number of pipes require 76 or 108)

Pipe wall hole size: 6mm 8mm

Pipe wall thickness: 3.5mm (the national standard is 3.5mm, but many projects often use non-standard pipes with a thickness less than 3.5mm in order to save money)

Tip length: 100mm, 150mm or 200mm (200mm tip length is less required)

Pipe length: less than 6 meters

Reinforcement principle

The advanced grouting small catheter pre-grouting is a construction measure in which a small conduit with holes in the pipe wall is driven into the pipe wall at a certain angle along the outer contour of the excavated tunnel or underground project, and grouting fluid is injected into the pipe at a certain pressure. It can not only pre-reinforce the rock and soil surrounding the cavern, but also play a role in advance pre-support. It is suitable for areas such as sand layers, sandy pebble (gravel) layers, fault fracture zones, shallow burials in weak surrounding rocks, and landslide processing where the self-stabilizing time is very short or has no self-stabilizing ability.

The pre-grouting construction of small catheter is simple and the grouting time is short. It can achieve the purpose of reinforcement, anti-seepage and plugging, so it is widely used. Pre-reinforcement of surrounding rock by small conduit grouting in advance is to inject solidified materials (usually cement slurry, water glass or polyurethane, etc.) into the crack channels in advance to fill the weathered broken rock under the surface soil and the broken rock surface that is difficult to support due to the development of structural fissures. It can seal cracks, block water inflow, cement rocks, improve the mechanical properties of surrounding rocks, increase the overall strength of the rock mass itself, and change the support state of surrounding rocks. The main function is to improve the shear strength of the rock mass around the pipe body, to strengthen the surrounding rock and diffuse the surrounding rock pressure.

The use of The advanced grouting small catheter in soft tunnel surrounding rock has many advantages:

(1) An advanced support system combining small catheter and consolidation is formed to improve the stability of the surrounding rock, inhibit the relaxation and deformation of the surrounding rock, and increase construction safety.

(2) The reinforcement effect is stable and reliable, and the grouting quality is easy to control.

(3) Using advanced support methods and adjusting the slurry solidification time can greatly shorten the underground excavation process time.

(4) Small machinery is used for construction, no special equipment is required, the process operation is simple, and it can be performed on general construction sites.

Scope of application

(1) Tunneling construction in the shallow buried section of the tunnel entrance or in the soft and broken surrounding rock section.

(2) Auxiliary measures for tunnel excavation in water-rich, weak and broken geology, gravel strata, karst geology and other unfavorable geological areas.

(3) Treatment of tunnel collapse.