Engineered for Extreme Environments in Oil & Gas, Power Generation, and Chemical Processing As a premier manufacturer of high-performance steel pipes and steel tubes, we specialize in advanced carbon steel alloys that defy industry limits. This guide answers critical questions from engineers and procurement specialists:

The following is a global carbon steel grade comparison and application guide clearly arranged by grade classification, covering China (GB), the United States (ASTM/SAE/UNS), Japan (JIS), Europe (EN/DIN), and international (ISO) standards and core application scenarios, and presented by steel type: 1. Ordinary carbon structural

Your Trusted Solution for Durable, Corrosion-Resistant Piping Systems As a leading manufacturer of plastic coated steel pipes, we specialize in delivering high-performance piping solutions that combine the strength of steel with the corrosion resistance of advanced polymer coatings. This guide explores the diverse applications, technical

The global carbon steel pipe market has undergone significant transformations since 2025, driven by evolving industrial demands, geopolitical shifts, and advancements in manufacturing technologies. As a trusted carbon steel pipe manufacturer in China, Tianjin xiangliyuan steel is committed to providing clients with data-driven insights into

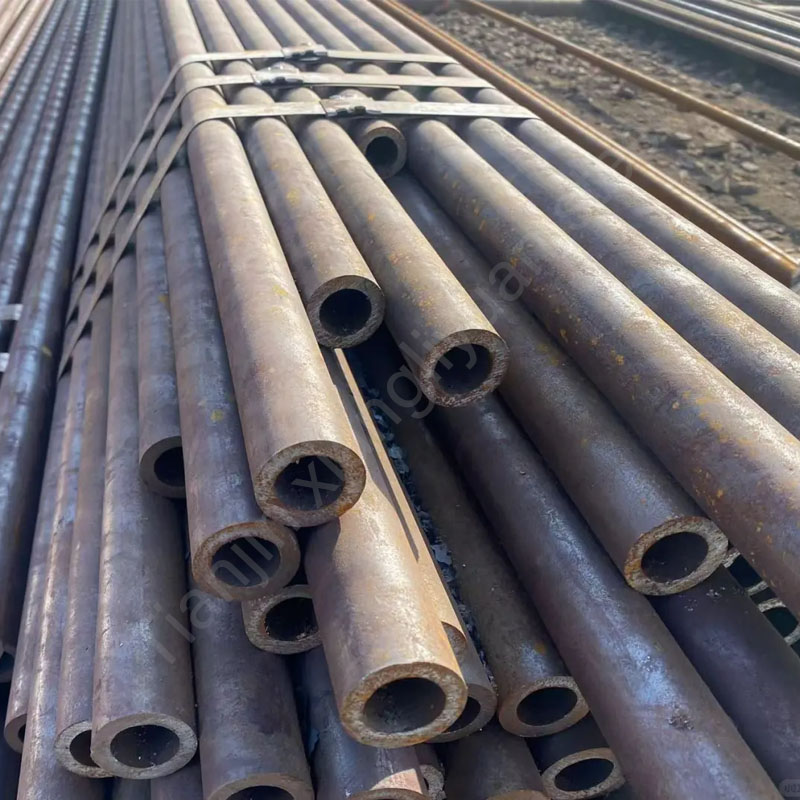

Unlocking Superior Strength, Safety, and Longevity for Critical Applications As a trusted manufacturer of seamless steel pipes, we empower industries to achieve unmatched reliability in high-pressure, high-temperature, and corrosive environments. This guide answers the #1 question from engineers and procurement managers: “How do seamless tubes

High pressure chemical fertiliser pipes are critical components in modern agricultural and industrial fertilizer production systems. Designed to withstand corrosive chemicals, extreme pressures, and elevated temperatures, these specialized pipes ensure safe and efficient transportation of raw materials like ammonia, urea, phosphoric acid, and nitrogen compounds.

In the global energy infrastructure, pipeline systems play a vital role in transporting oil and gas efficiently and safely over long distances. At the heart of these systems lies the API 5L pipeline pipe, a product engineered to meet rigorous industry standards for durability, strength,

In modern agriculture, greenhouses are essential for optimizing crop growth and protecting plants from harsh environmental conditions. Among the critical components of greenhouse structures, galvanized steel tubes stand out for their durability, corrosion resistance, and cost-effectiveness. This article explores the technical specifications, international standards, applications,

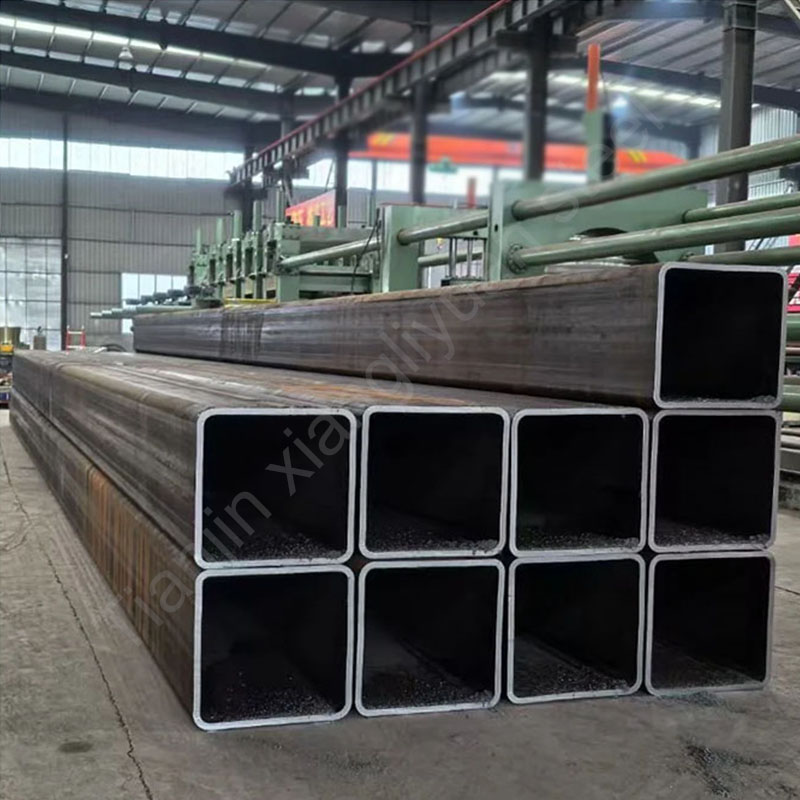

Structural steel tubes are indispensable components in modern construction, manufacturing, and infrastructure projects. Among these, welded structural tubes—including square steel tubes, ERW steel tubes, and specialized products like greenhouse tubes—are widely used due to their versatility, strength, and cost-effectiveness. This article explores their materials, international

The global energy sector relies heavily on oil pipelines and gas pipelines to transport hydrocarbons safely and efficiently. At the heart of these systems lie seamless pipes and welded pipes, engineered to meet rigorous industry standards. This article explores the technical aspects of pipeline pipes,