Black square tube, also known as carbon steel square tube, is a hollow steel tube with a square or rectangular cross-section. It is named because it has a black metal surface without surface treatment (such as galvanizing or painting). Black square tubes are widely used

I. Materials and steel grades of seamless steel pipes and welded steel pipes Seamless steel pipes and welded steel pipes use different materials and steel grades according to their uses and requirements. Common ones include: 1. Seamless steel pipes Seamless steel pipes are usually used

There are several common surface treatment methods for steel pipes. The process, characteristics and uses of each treatment method are as follows: 1. Hot-dip galvanizing - Process: Immerse the steel pipe in molten zinc liquid to make the zinc adhere to the surface to form

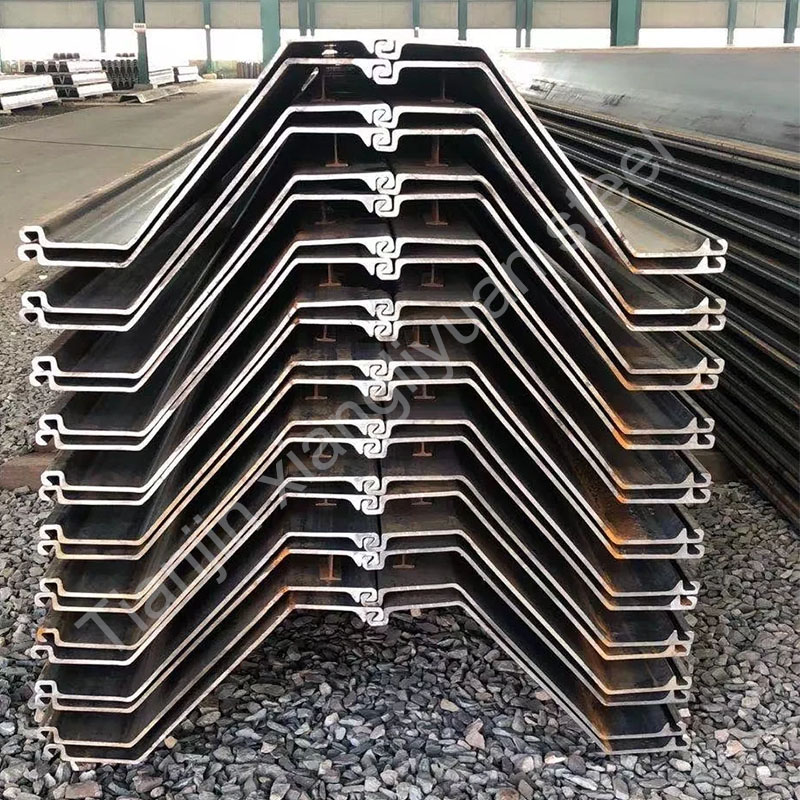

What is a Z-shaped steel sheet pile? Z-shaped steel sheet pile is a common type of steel sheet pile. Its cross-sectional shape is similar to the letter "Z" and is connected to each other by locks to form a continuous wall. Its design features make

How to change round seamless steel pipe into square steel pipe? Processing round seamless steel pipes into square seamless steel pipes is a common process requirement, which is usually used to meet specific engineering design requirements, such as building structures, machinery manufacturing or other

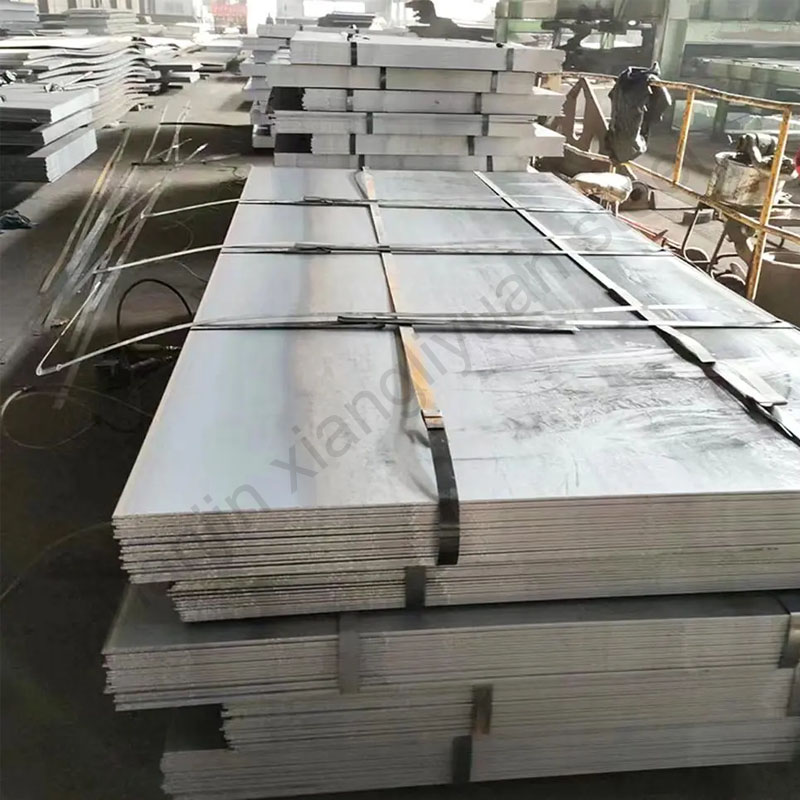

Carbon steel plate is a widely used steel in the steel industry. It is characterized by high strength, good toughness and good processing performance, and is suitable for a variety of engineering and manufacturing fields. 1. Main classification of carbon steel plates 1. Ordinary carbon

Carbon steel pipe elbows are connectors used to change the direction of pipeline fluids and are commonly found in pipeline systems in industries such as petroleum, natural gas, chemical, and electric power. Elbows are classified into three basic types: 45°, 90°, and 180°. Special angles

Spiral welded pipe is a common type of steel pipe, and spiral welding technology is used in its manufacturing process. Spiral welded pipe has good strength and pressure resistance due to its unique structural characteristics and manufacturing process, and is widely used in fields such

High-pressure boiler tubes are key components used in boiler systems and are subject to high-temperature and high-pressure working environments, so their performance requirements are extremely strict. Among the many types of boiler tubes, seamless steel tubes are widely used in the manufacture of high-pressure boiler

Oil and gas line pipes are steel pipes specially used for transporting fluids such as oil and natural gas. As a key component for oil and gas transportation, it not only needs to withstand high pressure, corrosion, and low temperature, but also must meet the