Procuring steel pipes for your industrial or construction project is a critical path activity. The right pipes ensure structural integrity, system efficiency, and long-term safety. The wrong choice can lead to catastrophic failures, costly delays, project overruns, and significant legal liabilities. In the global marketplace,

In industrial and construction applications, the true value of a steel pipe is measured not just by its initial cost or specifications, but by its proven reliability and durability over decades of service. Premature failure, corrosion, or maintenance issues can lead to catastrophic downtime, safety

Choosing the correct steel pipe is a critical decision impacting the safety, cost, and longevity of any project. The core of this decision lies in understanding the intrinsic properties of the pipe material itself. At Tianjin Xiangliyuan Steel, we specialize in manufacturing pipes from a

The steel pipes that form the arteries of global industry are masterpieces of modern engineering, born from a symphony of precision processes, advanced metallurgy, and relentless quality control. For professionals in procurement, engineering, and project management, understanding these manufacturing nuances is key to specifying the

In the vast ecosystem of industrial materials, steel pipes are not a monolithic product but a diverse family of engineered solutions, each designed to excel in specific, often demanding, environments. From the deepest oil wells to the tallest skyscrapers and the most complex industrial plants,

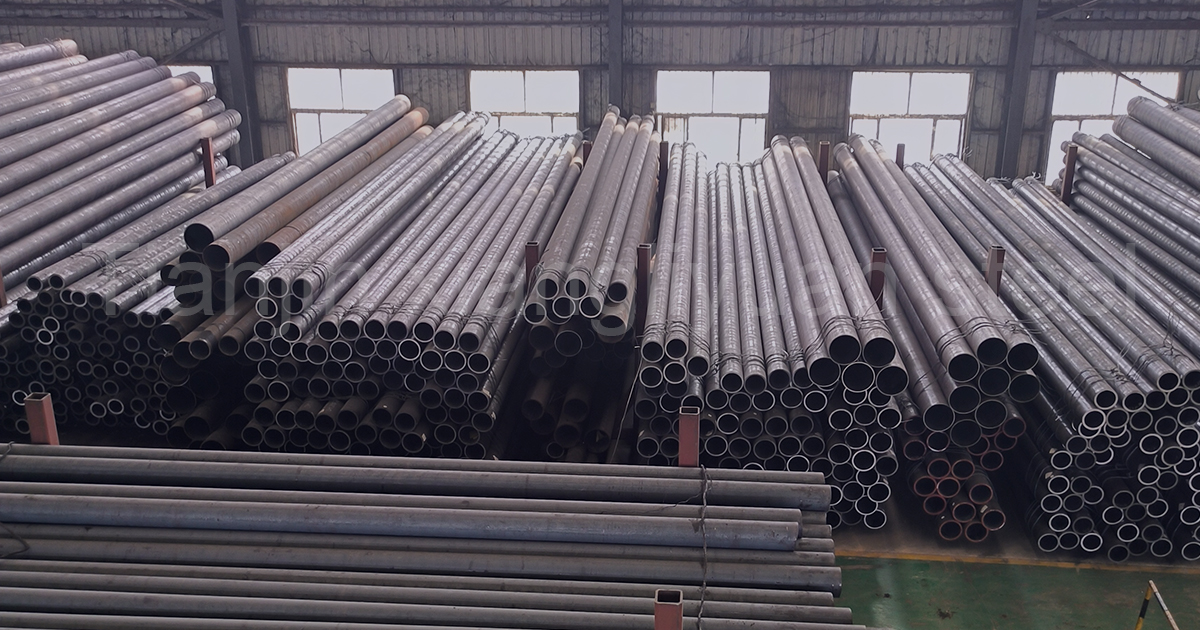

Steel pipes are the unsung heroes of modern infrastructure and industry. As a fundamental component in construction, energy, transportation, and manufacturing, they provide the essential conduits for fluids, gases, and structural support that keep our world functioning. At Tianjin Xiangliyuan Steel, we have dedicated ourselves

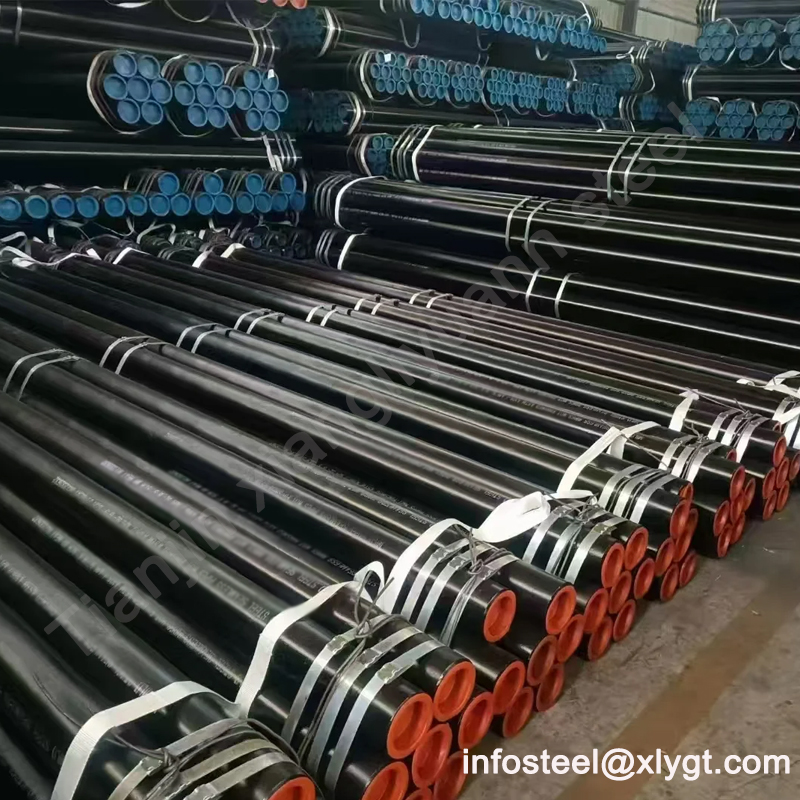

In an interconnected world, the safe and efficient transportation of oil and natural gas is fundamental to global energy security and economic stability. At the very heart of this vast, often invisible network lie critical components: pipeline steel tubes. These are not merely pieces of

If you’ve ever marvelled at the smooth, powerful, and silent extension of a hydraulic cylinder in heavy machinery, or relied on the precise, unwavering movement in a high-performance industrial press, you’ve witnessed the quiet work of a masterpiece often overlooked: the honed tube. This isn’t

Let's be honest: sometimes the most remarkable solutions are the ones that do the simple jobs perfectly. In our world at Tianjin Xiangliyuan Steel, while we pride ourselves on producing high-alloy pipes for extreme conditions, we hold a special appreciation for a true industry workhorse:

When you’re in charge of a pipeline project, there’s a specific moment when "standard" grades no longer feel sufficient. It’s when the blueprints call for crossing a mountain pass, handling a significant pressure surge, or navigating terrain where reliability is non-negotiable. You need a pipe