The following is a global carbon steel grade comparison and application guide clearly arranged by grade classification, covering China (GB), the United States (ASTM/SAE/UNS), Japan (JIS), Europe (EN/DIN), and international (ISO) standards and core application scenarios, and presented by steel type: 1. Ordinary carbon structural

Your Trusted Solution for Durable, Corrosion-Resistant Piping Systems As a leading manufacturer of plastic coated steel pipes, we specialize in delivering high-performance piping solutions that combine the strength of steel with the corrosion resistance of advanced polymer coatings. This guide explores the diverse applications, technical

The global carbon steel pipe market has undergone significant transformations since 2025, driven by evolving industrial demands, geopolitical shifts, and advancements in manufacturing technologies. As a trusted carbon steel pipe manufacturer in China, Tianjin xiangliyuan steel is committed to providing clients with data-driven insights into

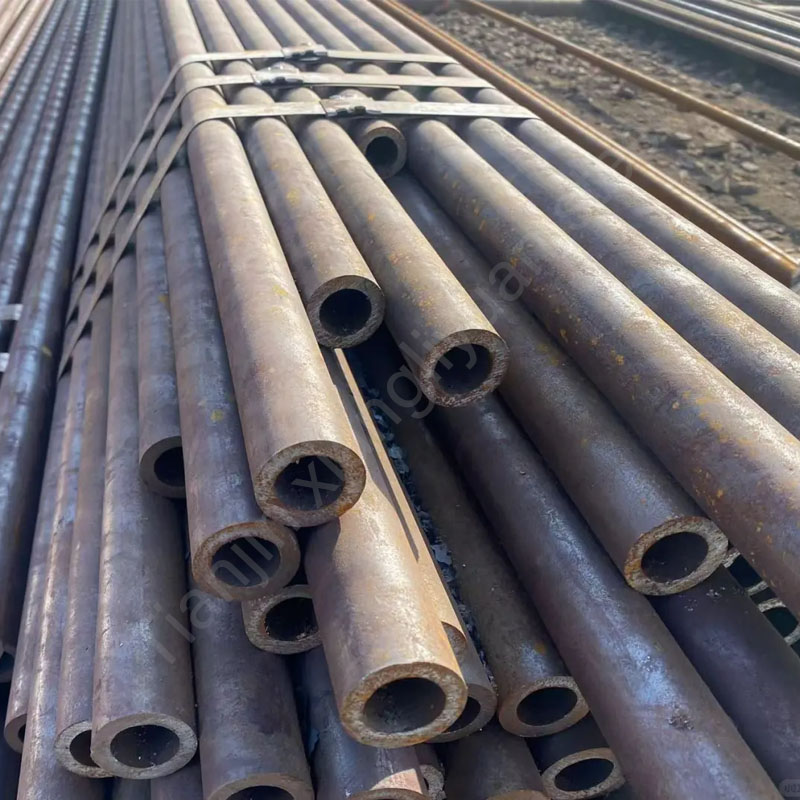

Unlocking Superior Strength, Safety, and Longevity for Critical Applications As a trusted manufacturer of seamless steel pipes, we empower industries to achieve unmatched reliability in high-pressure, high-temperature, and corrosive environments. This guide answers the #1 question from engineers and procurement managers: “How do seamless tubes

Your Ultimate Guide to High-Performance Carbon Steel Square and Rectangular Tubing As a leading manufacturer of seamless square tubes (ASTM-certified square steel tubing), we deliver precision-engineered solutions for industries demanding unmatched strength and durability. This guide answers critical buyer questions: What are the primary uses

Your Guide to High-Performance Steel Tubes for Power Plants and Industrial Boilers As a trusted manufacturer of steel boiler tubes, we empower industries worldwide with materials engineered to withstand extreme temperatures and pressures. This guide answers critical questions like: What materials are best for high-pressure

Introduction to Low Temperature Seamless Pipes Low temperature seamless pipes are specialized steel tubes engineered to perform reliably in extreme sub-zero environments, typically ranging from -50°C (-58°F) to -196°C (-321°F). These pipes are critical for industries such as liquefied natural gas (LNG) processing, cryogenic storage,

High pressure chemical fertiliser pipes are critical components in modern agricultural and industrial fertilizer production systems. Designed to withstand corrosive chemicals, extreme pressures, and elevated temperatures, these specialized pipes ensure safe and efficient transportation of raw materials like ammonia, urea, phosphoric acid, and nitrogen compounds.

Introduction to Petroleum Cracking Pipes Petroleum cracking pipes, also known as oil cracking pipes, are specialized steel tubes designed for use in high-temperature and high-pressure environments within refineries, petrochemical plants, and chemical processing facilities. These pipes are critical components in processes like fluid catalytic cracking

Boiler tubes are critical components in industrial and commercial heating systems, power generation plants, and various high-temperature applications. Designed to withstand extreme pressure, temperature, and corrosive environments, these tubes ensure efficient heat transfer and system longevity. 1. What Are Boiler Tubes? Boiler tubes are seamless