As a premier manufacturer in China's steel pipe industry, we are committed to providing reliable and cost-effective solutions for energy transportation and industrial infrastructure worldwide. Among our extensive product portfolio, API 5L L245N steel pipe stands as a fundamental and widely specified grade for numerous

In the backbone of global infrastructure—from the water in your taps to the oil in your car and the framework of towering skyscrapers—lies a fundamental component: the carbon steel pipe. As a cornerstone of modern industry, choosing the right carbon steel pipe supplier is not

The global carbon steel pipe market has undergone significant transformations since 2025, driven by evolving industrial demands, geopolitical shifts, and advancements in manufacturing technologies. As a trusted carbon steel pipe manufacturer in China, Tianjin xiangliyuan steel is committed to providing clients with data-driven insights into

High pressure chemical fertiliser pipes are critical components in modern agricultural and industrial fertilizer production systems. Designed to withstand corrosive chemicals, extreme pressures, and elevated temperatures, these specialized pipes ensure safe and efficient transportation of raw materials like ammonia, urea, phosphoric acid, and nitrogen compounds.

The global energy sector relies heavily on oil pipelines and gas pipelines to transport hydrocarbons safely and efficiently. At the heart of these systems lie seamless pipes and welded pipes, engineered to meet rigorous industry standards. This article explores the technical aspects of pipeline pipes,

In industrial pipeline systems, LSAW and SSAW are two mainstream types of welded steel pipes. Although both belong to the category of arc welded steel pipes, they have significant differences in manufacturing process, structural performance and engineering applications. 1. Essential differences in manufacturing processes 1.

I. Materials and steel grades of seamless steel pipes and welded steel pipes Seamless steel pipes and welded steel pipes use different materials and steel grades according to their uses and requirements. Common ones include: 1. Seamless steel pipes Seamless steel pipes are usually used

Welded steel pipe weld seam style and characteristics According to the weld seam form and processing technology, welded steel pipe is mainly divided into straight seam welded pipe, spiral welded pipe and other special weld seam forms (such as girth welding, spot welding). Different weld

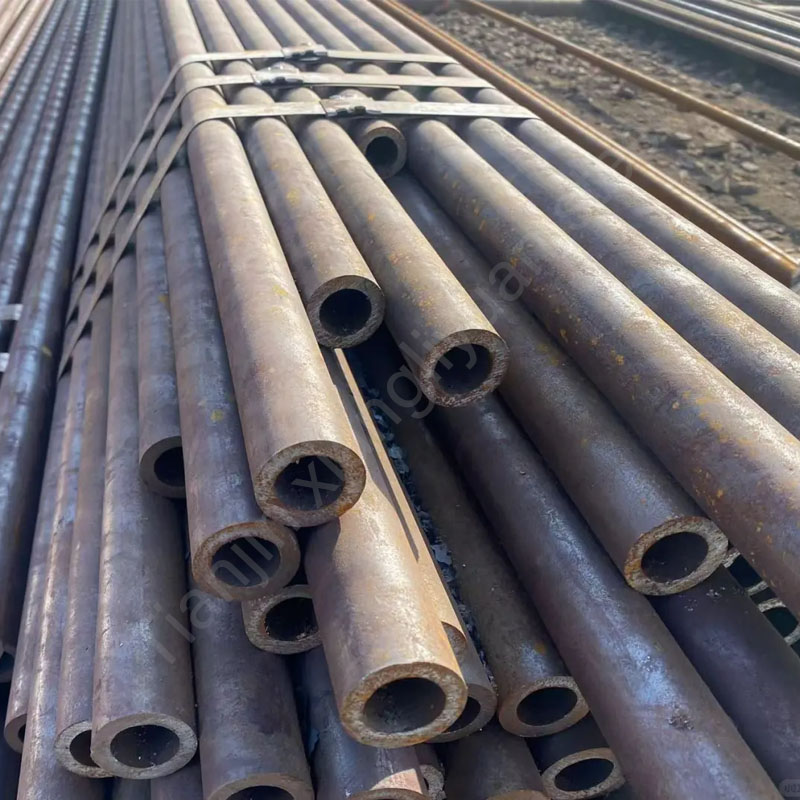

Seamless steel pipes and welded pipes (including straight seam welded pipes and spiral welded pipes) have significant differences in manufacturing processes, performance, uses and costs. The following is a detailed comparison of the advantages and disadvantages of the two: Advantages of seamless steel pipe No

The caliber range of welded steel pipes is very wide. The specific caliber models vary according to different standards (such as national standard GB, American standard ASTM, European standard EN, etc.), but generally cover the following caliber classifications: 1. Nominal diameter (DN) Small diameter welded