If you’ve ever marvelled at the smooth, powerful, and silent extension of a hydraulic cylinder in heavy machinery, or relied on the precise, unwavering movement in a high-performance industrial press, you’ve witnessed the quiet work of a masterpiece often overlooked: the honed tube. This isn’t

Look around you. From the warmth of your home on a winter morning to the electricity powering your screen, there’s a high probability that energy traveled hundreds, if not thousands, of miles to reach you. This incredible journey often happens silently, unseen, through the veins

When you’re in charge of a pipeline project, there’s a specific moment when "standard" grades no longer feel sufficient. It’s when the blueprints call for crossing a mountain pass, handling a significant pressure surge, or navigating terrain where reliability is non-negotiable. You need a pipe

As a premier Chinese manufacturer specializing in high-performance steel pipes for demanding industrial applications, we recognize that material selection is critical for operational safety and longevity. Among our specialized product offerings, API 5L L245NS steel pipe stands out as a purpose-engineered grade designed to withstand

As a premier manufacturer in China's steel pipe industry, we are committed to providing reliable and cost-effective solutions for energy transportation and industrial infrastructure worldwide. Among our extensive product portfolio, API 5L L245N steel pipe stands as a fundamental and widely specified grade for numerous

As a leading manufacturer in China's precision steel pipe industry, we specialize in engineering and supplying high-performance materials for the world's most demanding environments. Among our flagship products, WB36 alloy steel pipe stands as a premier choice for applications where exceptional strength, superior corrosion resistance,

As a leading manufacturer in China’s steel pipe industry, we specialize in producing high-performance alloy steel pipes that meet rigorous global standards. Among our flagship products, Cr5Mo (also known as ASTM A335 P5) alloy steel pipes stand out for their exceptional high-temperature strength, corrosion resistance,

In the competitive landscape of heavy industry, mining, and high-performance machinery, engineering demands continuously evolve toward greater power, efficiency, and durability. When component failure is not an option under extreme stress, impact, and fatigue loads, material science provides a definitive answer: 42CrMo alloy steel pipe.

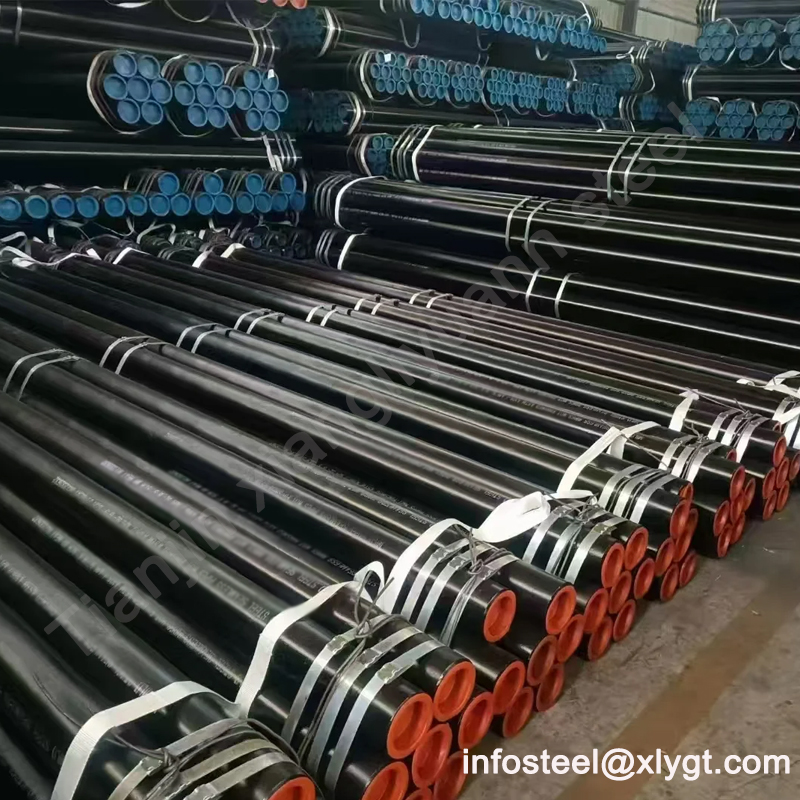

In the world of construction, strength meets vision. From the skeletal frames of skyscrapers to the elegant curves of modern architectural landmarks, carbon steel pipes provide the essential balance of durability, versatility, and cost-effectiveness that builders and architects rely upon. While other industries focus on

While large-diameter pipes form the backbone of global infrastructure, a different world of carbon steel tubing exists—one where precision, consistency, and flawless performance are paramount. In the realm of advanced machinery, automotive systems, and precision instruments, the unsung heroes are high-quality, cold-drawn carbon steel tubes.