The global carbon steel pipe market has undergone significant transformations since 2025, driven by evolving industrial demands, geopolitical shifts, and advancements in manufacturing technologies. As a trusted carbon steel pipe manufacturer in China, Tianjin xiangliyuan steel is committed to providing clients with data-driven insights into

High pressure chemical fertiliser pipes are critical components in modern agricultural and industrial fertilizer production systems. Designed to withstand corrosive chemicals, extreme pressures, and elevated temperatures, these specialized pipes ensure safe and efficient transportation of raw materials like ammonia, urea, phosphoric acid, and nitrogen compounds.

Welded steel pipe weld seam style and characteristics According to the weld seam form and processing technology, welded steel pipe is mainly divided into straight seam welded pipe, spiral welded pipe and other special weld seam forms (such as girth welding, spot welding). Different weld

The caliber range of welded steel pipes is very wide. The specific caliber models vary according to different standards (such as national standard GB, American standard ASTM, European standard EN, etc.), but generally cover the following caliber classifications: 1. Nominal diameter (DN) Small diameter welded

The following lists the various materials commonly used for welded steel pipes, covering common international standards: 1. Carbon steel materials 1. Ordinary carbon structural steel: - Q195, Q215, Q235, Q255, Q275 (Chinese standard) - SS330, SS400, SS490, SS540 (Japanese standard JIS G3101) - ASTM A53

Welded pipe, also known as welded steel pipe, is a type of steel pipe that is formed by bending steel plates or steel strips into shapes and then connecting them into pipes through welding processes. It is a type of steel pipe widely used in

JIS (Japanese Industrial Standards) provides systematic guidance for the production and application of steel pipes. JIS covers steel pipes made of a variety of materials, including carbon steel, stainless steel, alloy steel, etc. Each material is classified into different steel grades according to its chemical

ASTM (American Society for Testing and Materials) standards are widely used internationally, covering the chemical composition, mechanical properties, manufacturing process and other requirements of various materials. In the field of steel pipes, ASTM standards have specific specifications for different types of steel pipes. The following

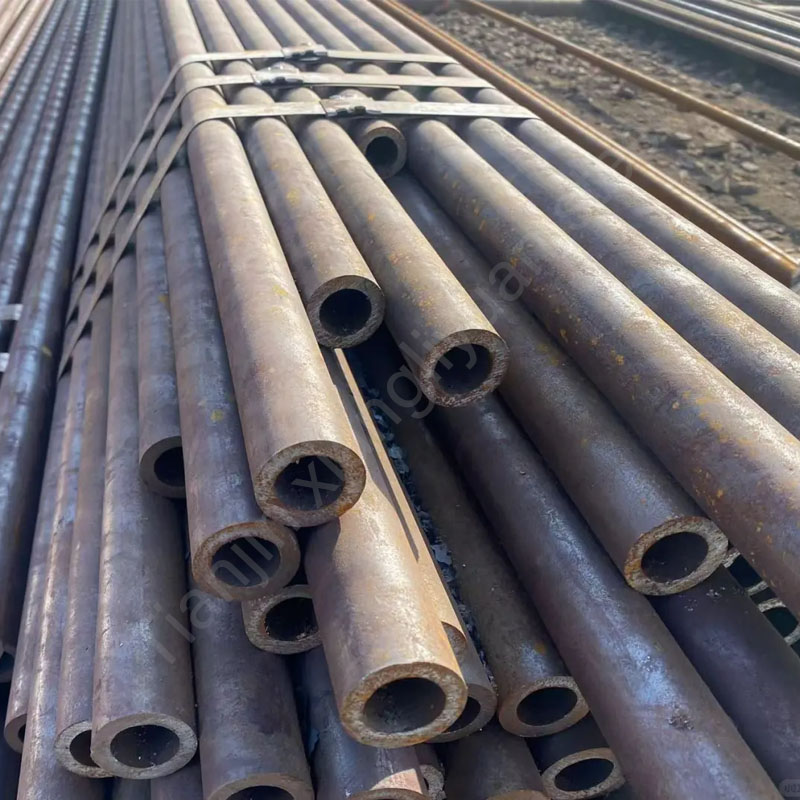

Seamless steel pipe and welded steel pipe are two common types of steel pipes, which have significant differences in manufacturing process, performance, application areas, etc. Seamless steel pipe manufacturing process: Seamless steel pipe is made directly from a whole piece of metal through processes such

Straight seam welded pipe (LSAW) and spiral welded pipe (SSAW) are two common types of welded steel pipes, which are widely used in oil and gas transportation, construction, infrastructure and other fields. Straight seam welded pipe (LSAW) Production process 1. Raw materials: steel plate or