The oil and gas industry operates at the frontier of engineering, where extreme pressures, corrosive environments, and unforgiving temperatures are the norm. In this high-stakes arena, the integrity of every component is paramount, with failure never being an option. This is especially true for the

In an interconnected world, the safe and efficient transportation of oil and natural gas is fundamental to global energy security and economic stability. At the very heart of this vast, often invisible network lie critical components: pipeline steel tubes. These are not merely pieces of

Look around you. From the warmth of your home on a winter morning to the electricity powering your screen, there’s a high probability that energy traveled hundreds, if not thousands, of miles to reach you. This incredible journey often happens silently, unseen, through the veins

Let’s be honest. When you're planning a pipeline project, you're not just moving a fluid from point A to point B. You're building a critical, long-lasting asset. You're balancing design pressures, terrain challenges, safety margins, and budget realities. You need a pipe that gives you

The global carbon steel pipe market has undergone significant transformations since 2025, driven by evolving industrial demands, geopolitical shifts, and advancements in manufacturing technologies. As a trusted carbon steel pipe manufacturer in China, Tianjin xiangliyuan steel is committed to providing clients with data-driven insights into

Seamless steel pipe: full analysis of materials, standards, specifications and industry applications

Seamless steel pipe (Seamless Steel Pipe) is an indispensable basic material in modern industry. With its excellent mechanical properties, high temperature and high pressure resistance and diversified specifications, it is widely used in petrochemical, machinery manufacturing, electric power, aerospace and other fields. This article will

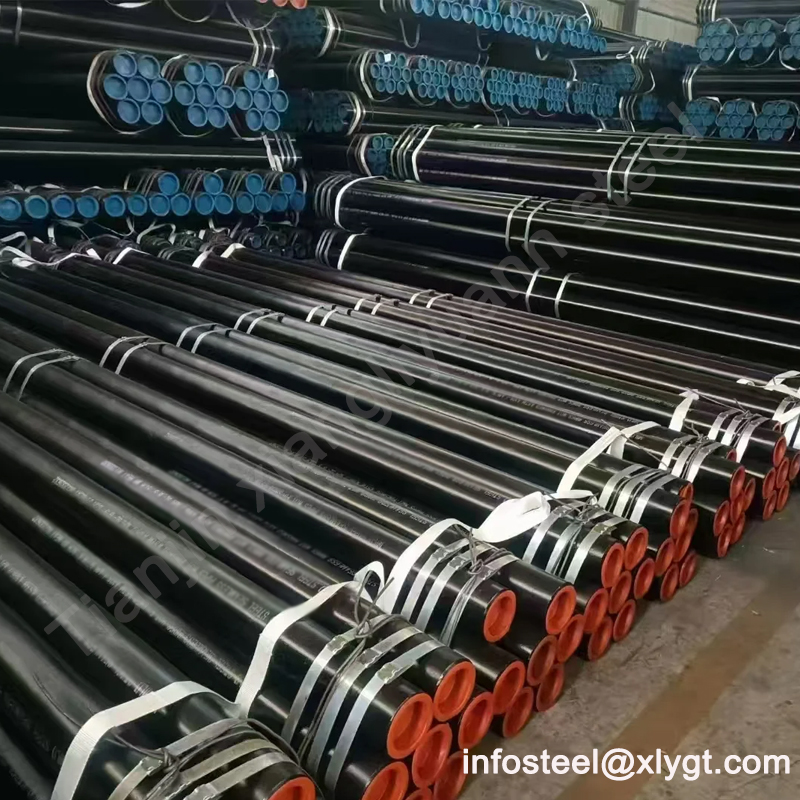

Seamless steel pipe is a pipe with a hollow cross-section and no seams around it. It is made by hot rolling, cold rolling or cold drawing. Due to its excellent mechanical properties and pressure resistance, it is widely used in petroleum, chemical, electric power, machinery

There are several common surface treatment methods for steel pipes. The process, characteristics and uses of each treatment method are as follows: 1. Hot-dip galvanizing - Process: Immerse the steel pipe in molten zinc liquid to make the zinc adhere to the surface to form

Oil and gas line pipes are steel pipes specially used for transporting fluids such as oil and natural gas. As a key component for oil and gas transportation, it not only needs to withstand high pressure, corrosion, and low temperature, but also must meet the

During the use of industrial carbon steel pipes, color marking is usually used to distinguish different media, pressure levels and uses. These color markings can improve work efficiency, reduce the risk of misoperation, and provide a basis for rapid identification in emergency situations. The following