In the backbone of global infrastructure—from the water in your taps to the oil in your car and the framework of towering skyscrapers—lies a fundamental component: the carbon steel pipe. As a cornerstone of modern industry, choosing the right carbon steel pipe supplier is not

Your Technical Guide to Selecting Optimal Steel Grades for Pipes, Tubes, and Structural Components As a premier manufacturer of carbon steel pipes, steel tubes, and steel bars, we engineer precision-grade materials for diverse industrial demands. This guide cuts through the confusion surrounding SAE 1025 (25#)

Choosing the Right Material for Your Industrial and Construction Projects As a professional steel pipe manufacturer, we understand that selecting the appropriate material is critical for your project’s success. Two commonly compared grades—20# steel (SAE 1020) and 45# steel (SAE 1045)—often spark questions like: “What

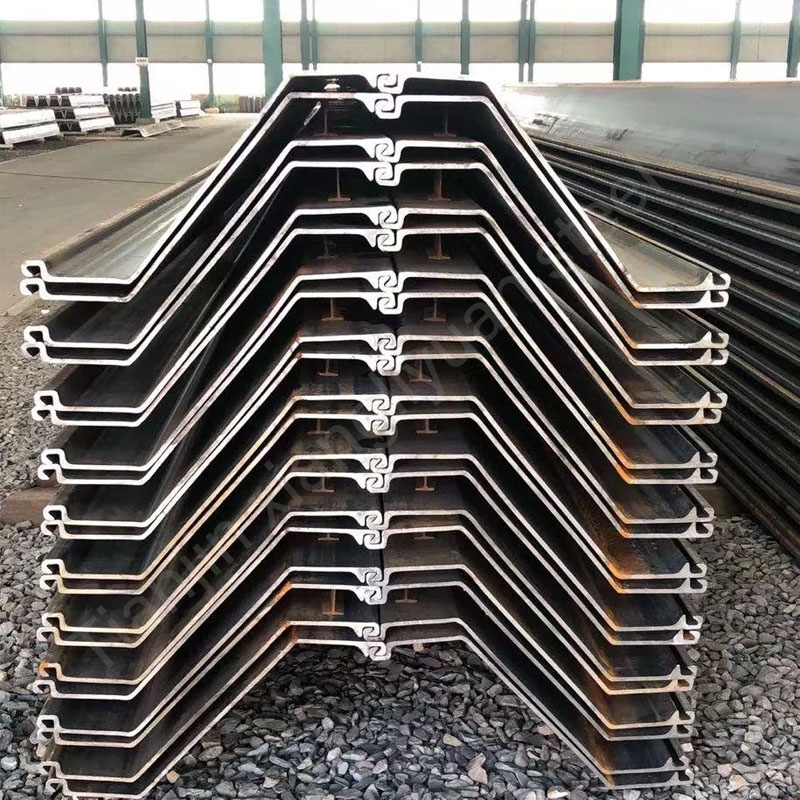

Introduction to Steel Sheet Piles Steel sheet piles, also known as sheet piling or steel piling, are interlocking steel sections driven into the ground to create retaining walls, cofferdams, flood barriers, and foundation supports. Their unique design—featuring a series of grooves and tongues—allows them to

Seamless steel pipe: full analysis of materials, standards, specifications and industry applications

Seamless steel pipe (Seamless Steel Pipe) is an indispensable basic material in modern industry. With its excellent mechanical properties, high temperature and high pressure resistance and diversified specifications, it is widely used in petrochemical, machinery manufacturing, electric power, aerospace and other fields. This article will

Common materials and steel grades for seamless steel pipes Depending on the material and purpose of seamless steel pipes, a variety of steel grades and materials are used to meet different technical requirements. The following is a classification of common seamless steel pipe materials and

The following lists the various materials commonly used for welded steel pipes, covering common international standards: 1. Carbon steel materials 1. Ordinary carbon structural steel: - Q195, Q215, Q235, Q255, Q275 (Chinese standard) - SS330, SS400, SS490, SS540 (Japanese standard JIS G3101) - ASTM A53

Cold-rolled carbon steel pipe is a carbon steel pipe product produced by cold rolling process. It has high precision and surface quality and is suitable for precision machinery, automobile manufacturing, construction and furniture industries. Compared with hot-rolled steel pipe, cold-rolled steel pipe has higher dimensional

High-pressure boiler tubes are pipes used in boiler systems to withstand high temperatures and high pressures, and are usually required to have high strength, high temperature resistance and corrosion resistance. The materials of high-pressure boiler tubes usually include the following: Carbon steel: such as 20G

Seamless steel pipes can be divided into the following categories according to different manufacturing processes, materials and uses: 1. Classification by production process Hot-rolled seamless steel pipe: produced by high-temperature rolling, suitable for high strength and high toughness requirements, widely used in machinery, construction, oil