Hot-rolled carbon steel coils use continuous casting slabs or blooming slabs as raw materials. They are heated in a heating furnace, descaled with high-pressure water, continuously rolled in rough rolling mills and finishing mills, and then cooled by laminar flow and rolled

Electric resistance welded (ERW) pipe is made from steel coil and the weld seam runs parallel to the pipe. The width of the coil is the same as the circumference of the pipe so diameters are limited to 24 inches. However, because

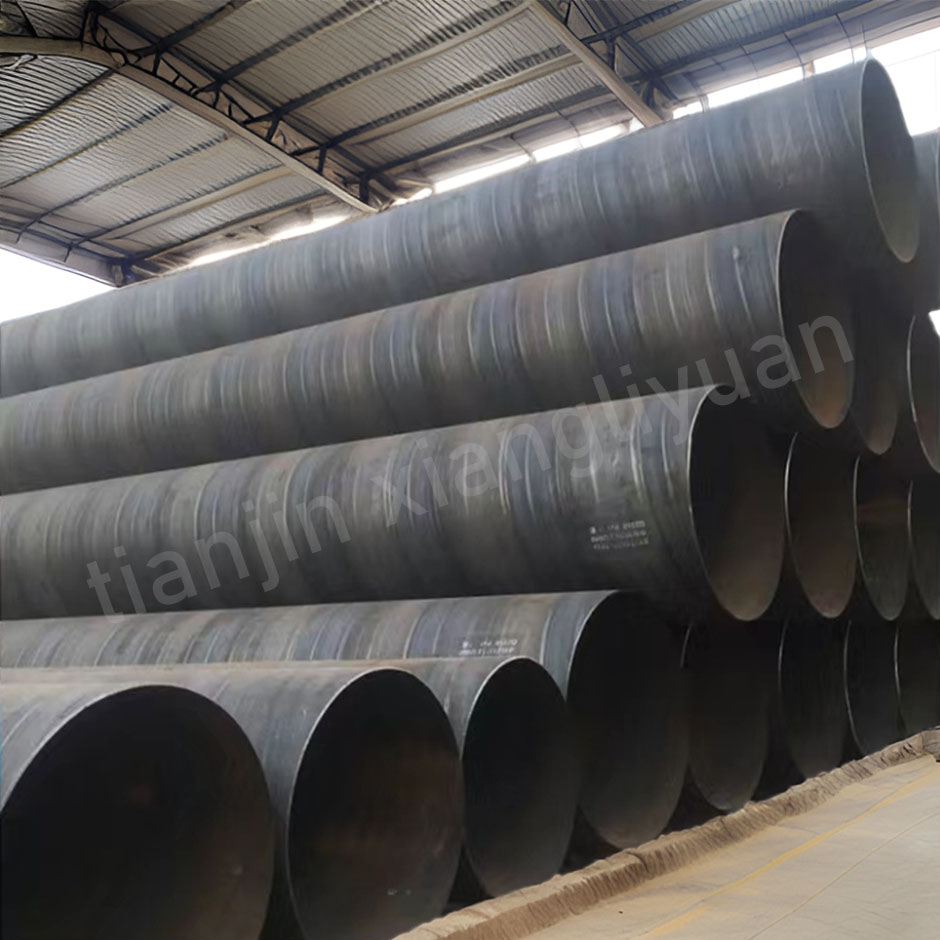

Spiral-welded pipe is manufactured from coils of steel that are unwound and flattened. The flattened strip is formed by right-angle rollers into a cylinder of the desired diameter.Spiral-welded pipes are available in sizes from 600 mm to 3650 mm. Implementation standards:GB/T 8162,

Reducer is a type of pipe fitting used for pipe diameters. The commonly used forming processes are reducing diameter pressing, expanding diameter pressing or reducing diameter plus expanding diameter pressing. For certain specifications of reducers, stamping can also be used. Classification: 1.

Honed pipe/tube are precision seamless pipes that have been cold-drawn or cold-rolled with high dimensional accuracy and good surface finish. They are suitable for mechanical structures and hydraulic equipment. Using precision seamless steel pipes to manufacture mechanical structures or hydraulic equipment can

Precision pipe is the carbon, alloy or stainless steel pipe with high precision sizes. Usually it has been made through hot rolling or cold drawn (cold rolling) processes. The internal and external diameter could control within +/-