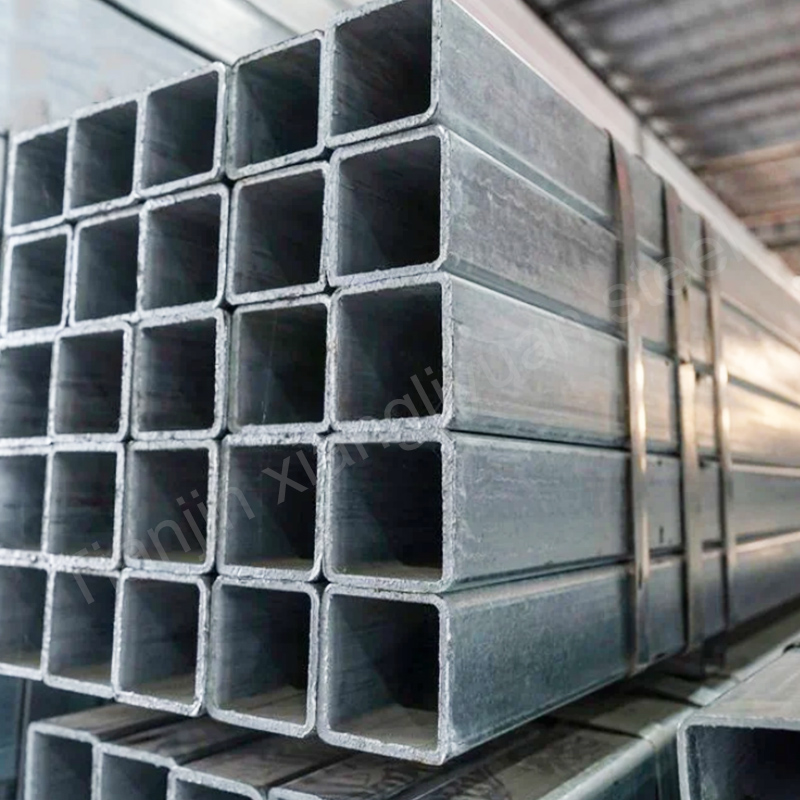

- Galvanized square pipes are generally made of welded square pipes or seamless square pipes as raw materials through hot-dip galvanizing or electro-galvanizing processes.

- Hot-dip galvanized square tubes are square tubes made by curling and welding steel plates or steel strips in a hot-dip galvanizing pool through a series of chemical reactions or directly cold-bending and welding galvanized strips.

- Cold-dip galvanized square pipe is actually a square pipe formed by galvanizing by electro-galvanizing. Its main principle is to use zinc filler coating, and then apply it on the protected surface using any coating method. After drying a zinc filler coating forms.

- Hot-dip galvanized square tube process flow: Coil – Straighter – Rolling – Resistance welding – Working steel – Hot rolling forming treatment – Semi-formed square tube (hot forming) – Heating furnace – Hot forming – Cooling table – Straightening – Plating Hot-dip galvanizing in zinc pool—hot forming—cooling table—straightening—test delivery

- Cold galvanized square pipe process flow: chemical degreasing → hot water washing → water washing → electrolytic degreasing → hot water washing → water washing → strong corrosion → water washing → electroplating of zinc-iron alloy → water washing → water washing → light extraction → passivation → water washing → drying

- Characteristics of galvanized square pipe:

The galvanizing process makes it more protective and resistant to corrosion. The entire structure is made of zinc, forming a dense quaternary crystal. This crystal forms a barrier on the steel plate, thus effectively preventing corrosion factors from penetrating. Corrosion resistance comes from the strong protective barrier layer of zinc. When zinc provides sacrificial protection on trimmed edges, scratches, and scratched parts of the coating, the zinc forms an insoluble oxide layer and plays a barrier protective function. - Implementation standards:GB/T 8162, GB/T 8163, EN10147, EN10142, DIN 17162, JIS G3302, ASTM A653, etc.

- Steel grade:Dx51D,Dx52D,Dx53D,DX54D,S220GD,S250GD,S280GD,S350GD,S350GD,S550GD;SGCC,SGHC,SGCH,SGH340,SGH400,

SGH440,SGH490,SGH540,SGCD1,SGCD2,SGCD3,

SGC340,SGC340,SGC490,SGC570; SQ CR22 (230), SQ CR22 (255),SQ CR40 (275),SQ CR50 (340),SQ CR80(550),CQ,FS,DDS,EDDS,SQ CR33 (230),SQ CR37 (255),SQCR40 (275), SQ CR50 (340),SQ CR80 (550),etc. - Since galvanized square tubes are galvanized on square tubes, the application range of galvanized square tubes has been greatly expanded compared to square tubes. It is mainly used in curtain walls, construction, machinery manufacturing, steel construction projects, shipbuilding, solar power generation brackets, steel structure engineering, power engineering, power plants, agricultural and chemical machinery, glass curtain walls, automobile chassis, airports, etc.

Get A Quote Today

Best quality at the lowest price