- Carbon steel patterned plate is a carbon steel plate with regular patterns on the surface, which is widely used in construction, machinery, transportation and other fields.

- The material of

- Carbon steel patterned plate varies according to different application occasions and performance requirements. The following are common carbon steel checkered plate grades:

- Q235 series:

Q235A/B/C/D: Q235 is a common low-carbon steel series in China with good plasticity, toughness and weldability. Commonly used in building structures, bridges and ordinary mechanical parts.

Q235B is the most common steel grade, widely used in checkered plate manufacturing, suitable for general non-slip floors, pedals, etc.

Q345 series:

Q345A/B/C/D/E: Q345 is a low-alloy high-strength steel with high strength and good toughness. It is suitable for occasions with high strength requirements, such as engineering machinery, bridges, vehicles and other structural parts. Q345B is a more commonly used grade in this series.

SS400: Ordinary carbon structural steel in the Japanese JIS standard, with performance similar to Q235. SS400 steel plates are often used to make general building and mechanical structural parts, as well as patterned plates with low anti-slip performance requirements.

A36: Ordinary carbon structural steel in the US ASTM standard, commonly used in building and bridge structural parts. A36 steel has the same performance as Q235, has good weldability and mechanical properties, and is suitable for making patterned steel plates.

S235JR: Low carbon steel in the European EN standard, similar to China’s Q235. S235JR steel has good toughness and strength, and is often used to make patterned steel plates, suitable for general construction and industrial purposes.

Hot-dip galvanized carbon steel: In order to enhance corrosion resistance, some carbon steel patterned plates are hot-dip galvanized after production, and the common substrates are Q235 or Q345. Hot-dip galvanized carbon steel patterned plates are suitable for outdoor and humid environments, such as building scaffolding, ship decks, etc.

These steel grades of carbon steel patterned plates can meet the needs of different uses from general building structures to anti-slip floors for industrial equipment through different processing processes. When selecting steel grades, factors such as tensile strength, toughness, weldability and corrosion resistance are usually considered. - Pattern type

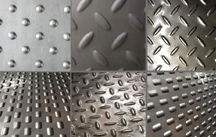

Single-rib pattern: also known as single-strip pattern plate, with only one raised pattern on the surface. Due to the single pattern, the anti-slip effect is average, suitable for occasions with mild anti-slip requirements.

Double-rib pattern: There are two parallel or staggered raised stripes on the surface, and the anti-slip effect is better than the single-rib pattern. It is suitable for places that require medium anti-slip performance, such as general factory passages or trails.

Three-rib pattern: There are three raised rib-like patterns on the surface. The three-rib pattern has a strong anti-slip effect and is suitable for wet or frequently walking environments, such as outdoor stairs and car floors.

Five-rib pattern (herringbone): The most common pattern type, with five evenly distributed raised stripes on the surface, arranged in a “herringbone” shape, so it is called a “herringbone pattern”. Five-rib pattern plates have the best anti-slip performance and are often used in places with high anti-slip requirements such as stair treads and public transportation floors.

Diamond pattern: The surface is a regular diamond-shaped protrusion, with strong friction and decorative effect, suitable for architectural decoration and workshop floor and other purposes.

Lentil pattern: The surface is a lentil-shaped protrusion pattern, with strong friction and unique appearance, suitable for specific industrial uses, such as anti-slip floors for mechanical equipment.

Different pattern types can not only play a beautiful role, but also meet different anti-slip and wear-resistant requirements. These pattern structures are usually formed by die pressing or hot rolling during the rolling process to ensure that the surface pattern is uniform and has good adhesion. - The production and quality control of carbon steel patterned plates are usually in accordance with the corresponding national or industry standards. The following are commonly used patterned carbon steel plate standards:

GB/T 3277-1991: This is China’s patterned steel plate standard, which specifies the technical conditions, size, shape, weight and inspection methods of patterned steel plates, and is suitable for patterned carbon steel plates for general purposes.

JIS G3101: This is the Japanese standard for patterned steel plates, which is applicable to low-carbon steel and low-alloy steel plates for general structures, and mainly covers material requirements and testing methods.

ASTM A786: This is the American standard for patterned steel plates, which is applicable to structures with high anti-slip requirements such as floors and stair treads.

EN 10025: This is the European standard for patterned steel plates, which covers carbon steel and low-alloy steel materials used for structures, and specifies chemical composition and mechanical properties.

Different standards have specific provisions for the dimensional tolerances, chemical composition, mechanical properties, etc. of patterned steel plates to ensure that the products meet the use requirements of various industries. - The main uses of carbon steel patterned plates/rolls are wide-ranging, covering multiple fields such as construction, machinery, and transportation:

Construction field: Patterned carbon steel plates are often used in floors, treads, stairs, corridors, etc., providing good anti-slip performance, especially suitable for crowded or humid environments such as subway stations, airports, factory workshops, etc.

Mechanical equipment: Patterned carbon steel plates are also widely used in protective covers, pedals and other parts of mechanical equipment. The surface patterns provide anti-skid and wear-resistant properties to protect the safety of operators.

Transportation field: In the transportation field, patterned carbon steel plates are used in vehicle floors, truck floor and pedals to improve the durability and safety of vehicles and equipment.

Decorative use: Patterned steel plates are also used for interior decoration to increase beauty and layering, such as floor or wall decoration in shopping malls, exhibition halls and other places.

Industrial use: In industrial environments such as factories, mines, and oil fields, patterned steel plates are used for floors, workbenches and other parts to effectively prevent slipping, ensure safe operation of workers, and reduce the risk of slipping and falling.

Get A Quote Today

Best quality at the lowest price