Discover the critical differences between hot-dip galvanizing and electro-galvanizing processes for steel pipes. Learn which method suits your project for durability, cost, and corrosion resistance. Introduction to Galvanized Steel Pipes Galvanized steel pipes are a cornerstone of modern industrial and construction projects due to their

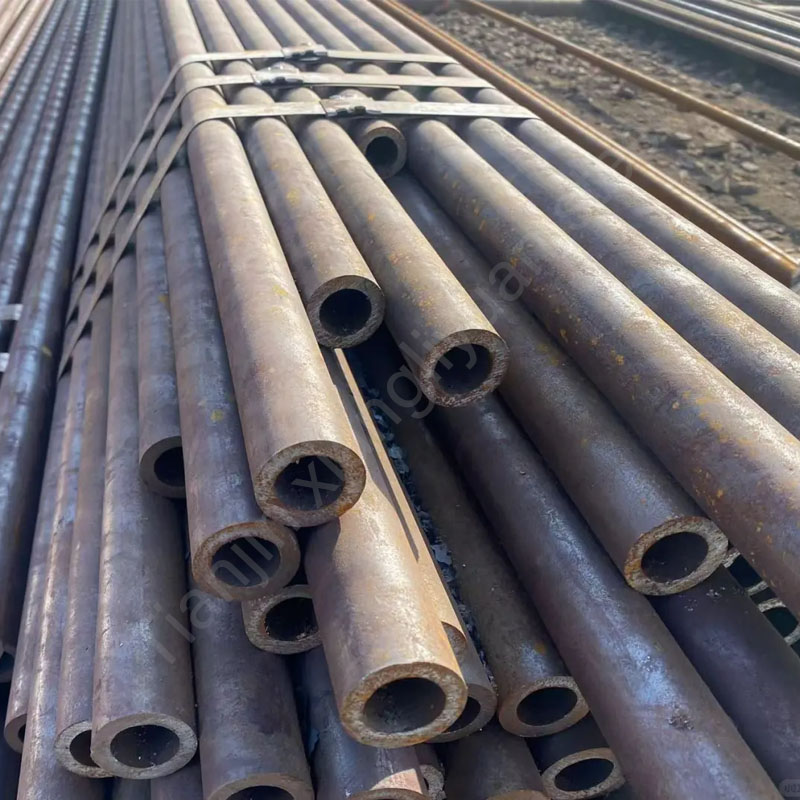

Introduction to Low Temperature Seamless Pipes Low temperature seamless pipes are specialized steel tubes engineered to perform reliably in extreme sub-zero environments, typically ranging from -50°C (-58°F) to -196°C (-321°F). These pipes are critical for industries such as liquefied natural gas (LNG) processing, cryogenic storage,

High pressure chemical fertiliser pipes are critical components in modern agricultural and industrial fertilizer production systems. Designed to withstand corrosive chemicals, extreme pressures, and elevated temperatures, these specialized pipes ensure safe and efficient transportation of raw materials like ammonia, urea, phosphoric acid, and nitrogen compounds.

Introduction to Petroleum Cracking Pipes Petroleum cracking pipes, also known as oil cracking pipes, are specialized steel tubes designed for use in high-temperature and high-pressure environments within refineries, petrochemical plants, and chemical processing facilities. These pipes are critical components in processes like fluid catalytic cracking

Boiler tubes are critical components in industrial and commercial heating systems, power generation plants, and various high-temperature applications. Designed to withstand extreme pressure, temperature, and corrosive environments, these tubes ensure efficient heat transfer and system longevity. 1. What Are Boiler Tubes? Boiler tubes are seamless

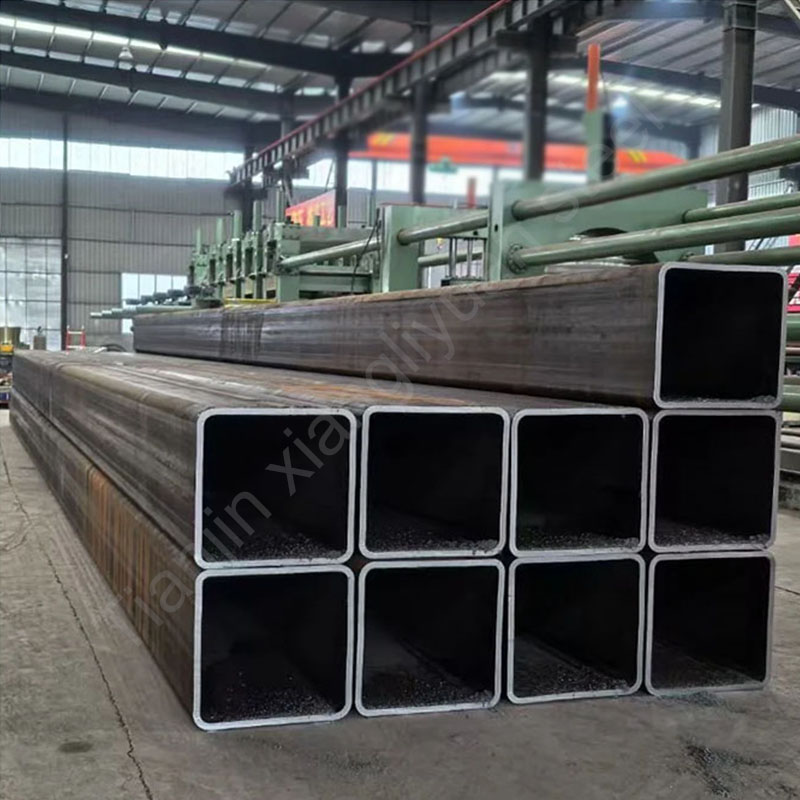

What Is a Galvanized Square Tube? A galvanized square tube (also called GI square tube or galvan square tube) is a cold-formed steel hollow section with equal side lengths, coated with zinc to prevent corrosion. These rectangular steel tubes combine structural strength with durability, making

In modern agriculture, greenhouses are essential for optimizing crop growth and protecting plants from harsh environmental conditions. Among the critical components of greenhouse structures, galvanized steel tubes stand out for their durability, corrosion resistance, and cost-effectiveness. This article explores the technical specifications, international standards, applications,

Structural steel tubes are indispensable components in modern construction, manufacturing, and infrastructure projects. Among these, welded structural tubes—including square steel tubes, ERW steel tubes, and specialized products like greenhouse tubes—are widely used due to their versatility, strength, and cost-effectiveness. This article explores their materials, international

The global energy sector relies heavily on oil pipelines and gas pipelines to transport hydrocarbons safely and efficiently. At the heart of these systems lie seamless pipes and welded pipes, engineered to meet rigorous industry standards. This article explores the technical aspects of pipeline pipes,

Fire fighting tubes are critical components of fire protection systems, designed to deliver water or fire-suppressing agents efficiently during emergencies. These tubes must meet stringent quality, durability, and safety standards to ensure reliable performance under high-pressure conditions. In this guide, we explore the materials, steel