Galvanized steel pipes stand as a cornerstone of modern infrastructure, offering unparalleled corrosion resistance and longevity. The essential process of coating steel pipes with a protective layer of zinc safeguards them from the relentless attack of moisture, chemicals, and environmental elements. At Tianjin Xiangliyuan Steel

For engineers, procurement specialists, and project managers sourcing piping systems globally, material selection isn't just a choice – it's a critical determinant of project success, safety, and longevity. While carbon steel serves many applications, demanding environments require the enhanced properties offered by alloy steel pipes.

The following is a global carbon steel grade comparison and application guide clearly arranged by grade classification, covering China (GB), the United States (ASTM/SAE/UNS), Japan (JIS), Europe (EN/DIN), and international (ISO) standards and core application scenarios, and presented by steel type: 1. Ordinary carbon structural

There are several common surface treatment methods for steel pipes. The process, characteristics and uses of each treatment method are as follows: 1. Hot-dip galvanizing - Process: Immerse the steel pipe in molten zinc liquid to make the zinc adhere to the surface to form

How to change round seamless steel pipe into square steel pipe? Processing round seamless steel pipes into square seamless steel pipes is a common process requirement, which is usually used to meet specific engineering design requirements, such as building structures, machinery manufacturing or other

Spiral welded pipe is a common type of steel pipe, and spiral welding technology is used in its manufacturing process. Spiral welded pipe has good strength and pressure resistance due to its unique structural characteristics and manufacturing process, and is widely used in fields such

High-pressure boiler tubes are key components used in boiler systems and are subject to high-temperature and high-pressure working environments, so their performance requirements are extremely strict. Among the many types of boiler tubes, seamless steel tubes are widely used in the manufacture of high-pressure boiler

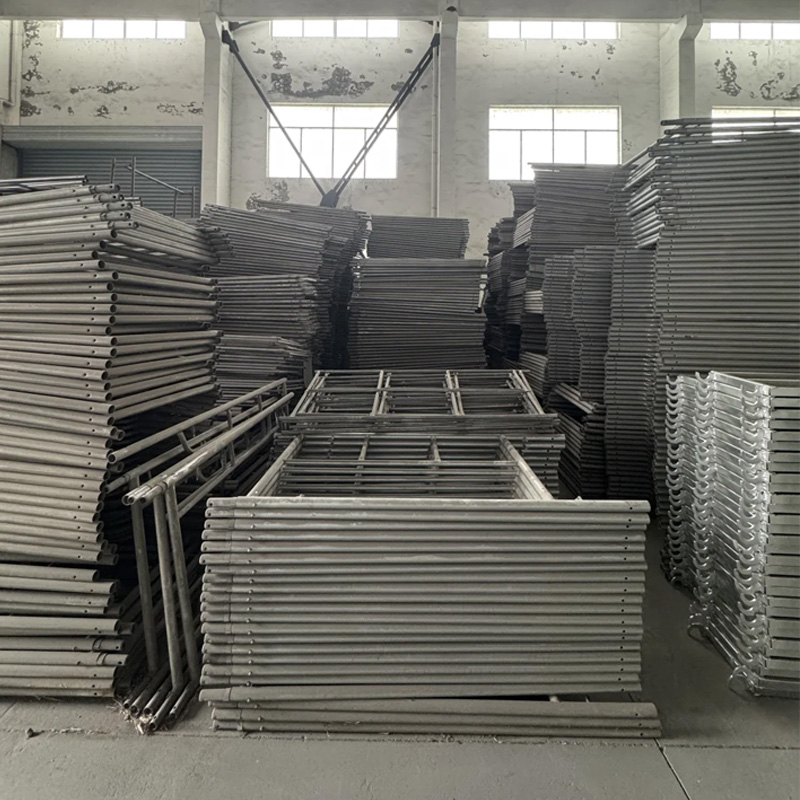

Scaffolding tubes are a type of temporary structural material commonly used in construction. They are mainly used to build scaffolding to provide a stable platform and safety guarantee for workers when working at heights. They are characterized by high strength, good durability, and easy installation.

Pre-galvanized steel pipe and hot-dip galvanized steel pipe are two common types of steel pipes. They are both treated with galvanizing process to improve the corrosion resistance and service life of steel pipes. Although both are galvanized steel pipes, there are obvious differences in production

During the use of industrial carbon steel pipes, color marking is usually used to distinguish different media, pressure levels and uses. These color markings can improve work efficiency, reduce the risk of misoperation, and provide a basis for rapid identification in emergency situations. The following