Introduction to Pipe Fittings in Industrial Systems When procuring steel pipes for any industrial, commercial, or construction application, selecting the appropriate pipe fittings is equally critical to ensuring system integrity, safety, and performance. Pipe fittings serve as the indispensable connectors, directors, and controllers within piping

In industrial and construction applications, the true value of a steel pipe is measured not just by its initial cost or specifications, but by its proven reliability and durability over decades of service. Premature failure, corrosion, or maintenance issues can lead to catastrophic downtime, safety

Choosing the correct steel pipe is a critical decision impacting the safety, cost, and longevity of any project. The core of this decision lies in understanding the intrinsic properties of the pipe material itself. At Tianjin Xiangliyuan Steel, we specialize in manufacturing pipes from a

The steel pipes that form the arteries of global industry are masterpieces of modern engineering, born from a symphony of precision processes, advanced metallurgy, and relentless quality control. For professionals in procurement, engineering, and project management, understanding these manufacturing nuances is key to specifying the

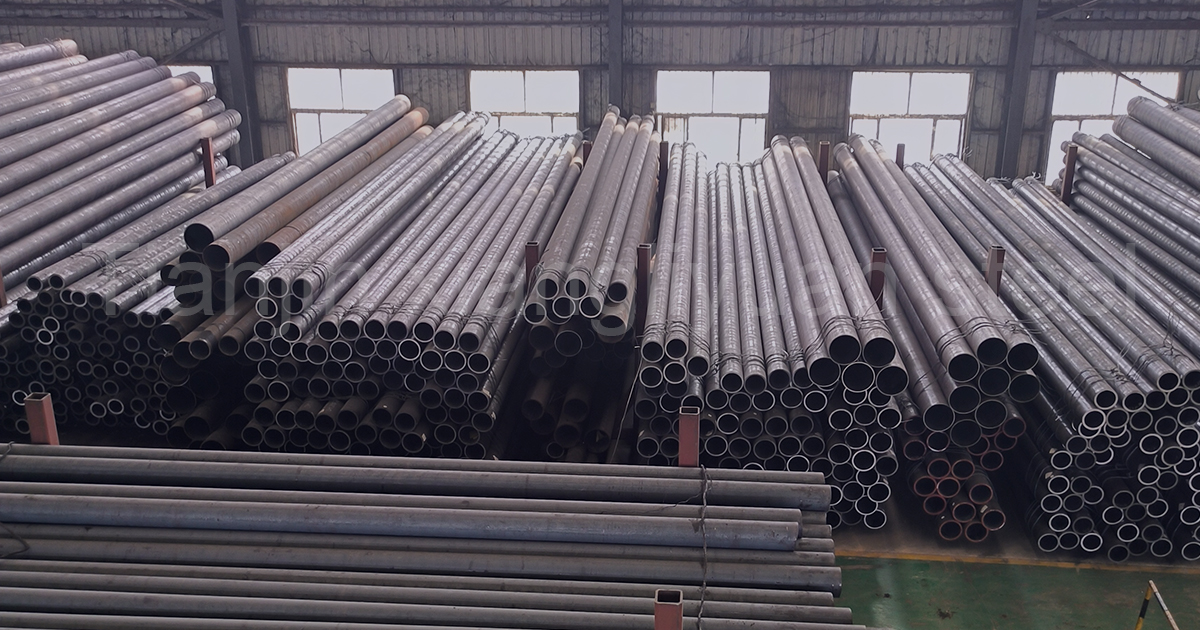

In the vast ecosystem of industrial materials, steel pipes are not a monolithic product but a diverse family of engineered solutions, each designed to excel in specific, often demanding, environments. From the deepest oil wells to the tallest skyscrapers and the most complex industrial plants,

Steel pipes are the unsung heroes of modern infrastructure and industry. As a fundamental component in construction, energy, transportation, and manufacturing, they provide the essential conduits for fluids, gases, and structural support that keep our world functioning. At Tianjin Xiangliyuan Steel, we have dedicated ourselves

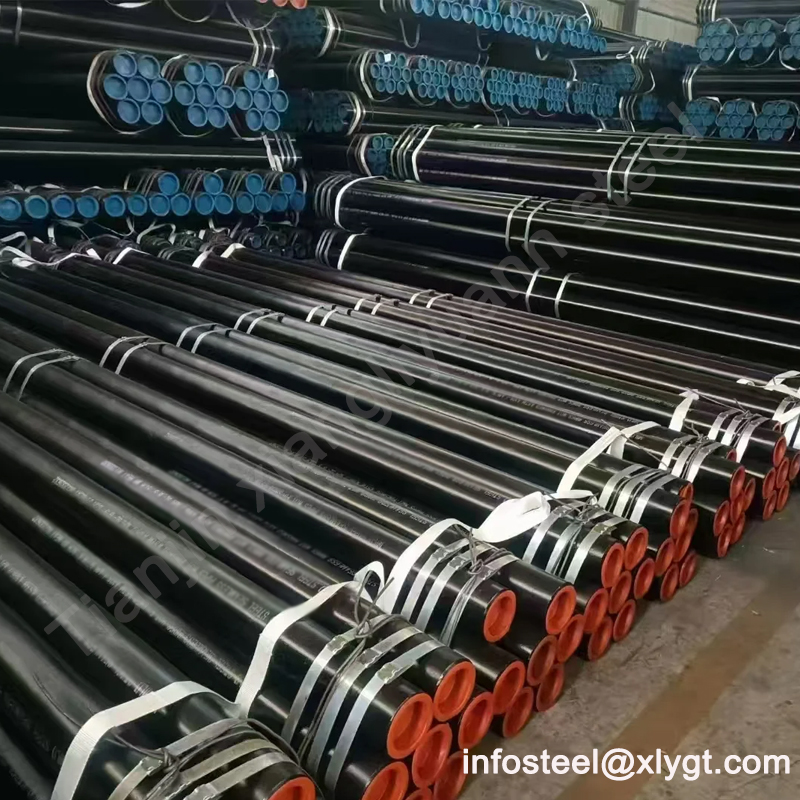

In an interconnected world, the safe and efficient transportation of oil and natural gas is fundamental to global energy security and economic stability. At the very heart of this vast, often invisible network lie critical components: pipeline steel tubes. These are not merely pieces of

In the world of power generation, petrochemical refining, and numerous high-temperature industrial applications, the integrity and performance of every component are non-negotiable. At the heart of these critical systems lie High-Pressure Boiler Tubes – engineered components that do much more than simply carry fluids. They

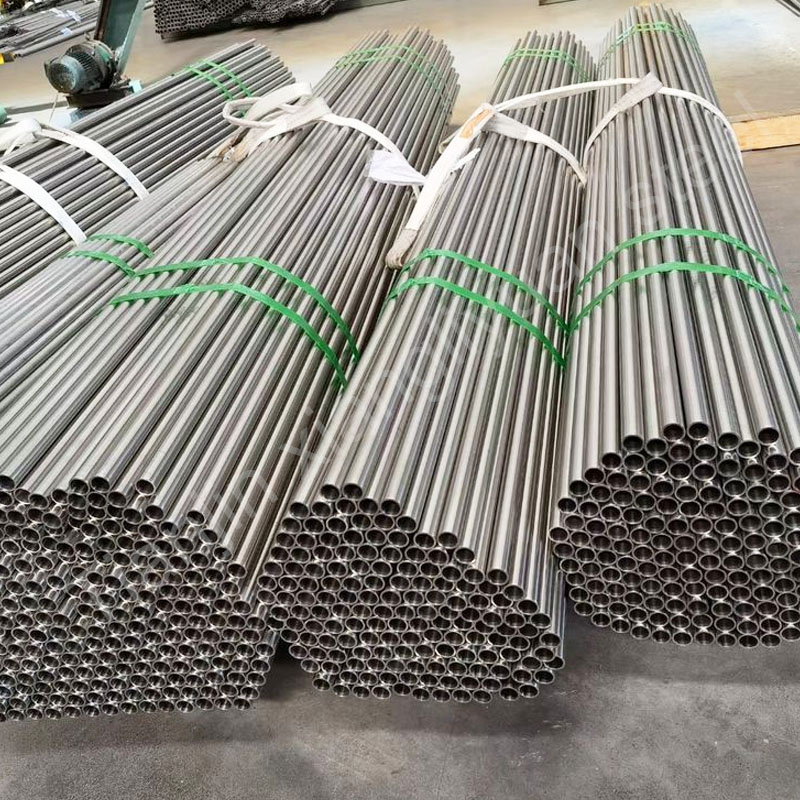

Seamless honed tubes are precision-engineered components critical to hydraulic and pneumatic systems, offering superior performance in demanding applications. Understanding their key product parameters is essential for engineers, procurement specialists, and OEMs worldwide. This comprehensive guide covers essential specifications, including material composition, dimensional tolerances, surface characteristics,

Seamless precision tubes are high-performance cylindrical hollow sections manufactured without welded seams, offering superior structural integrity, dimensional accuracy, and reliability for demanding applications. These tubes are essential across industries including hydraulic systems, pneumatic systems, automotive components, medical devices, aerospace engineering, and industrial machinery. This guide