The purpose of anti-corrosion treatment of steel pipes is to extend their service life, protect them from environmental factors, and avoid economic losses and safety hazards caused by corrosion. The specific reasons include the following: Extend life: Anti-corrosion treatment can significantly extend the service life

In the manufacture of metal facilities, hot-dip galvanizing and cold-dip galvanizing are two commonly used manufacturing processes. As a metal anti-corrosion method, hot-dip galvanizing usually puts the steel structure to be derusted into the molten zinc at about 500 °C, so that the zinc layer

PPGI stands for Pre-painted Galvanized Iron, which is a galvanized steel sheet or coil that has been pre-coated. The wide application of PPGI lies in its superior corrosion resistance and rich color selection, making it highly practical in the fields of construction, home appliances, furniture,

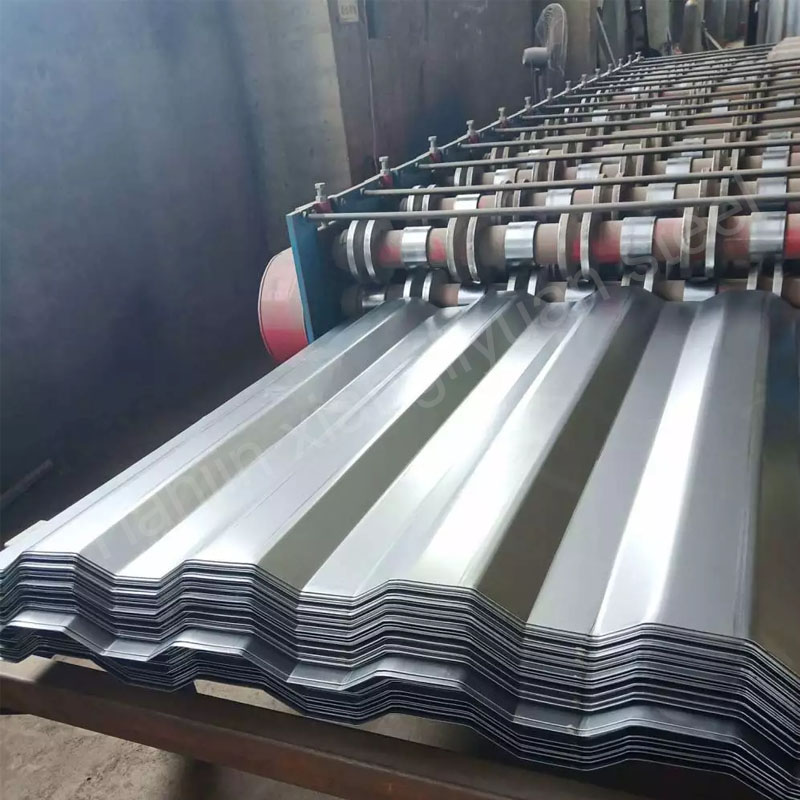

Galvanized corrugated steel sheet is a corrugated steel sheet with a galvanized surface. It has good corrosion resistance and mechanical strength and is widely used in building roofs, walls, fences and other fields. Production process of galvanized corrugated steel sheet Raw material preparation: Select high-quality

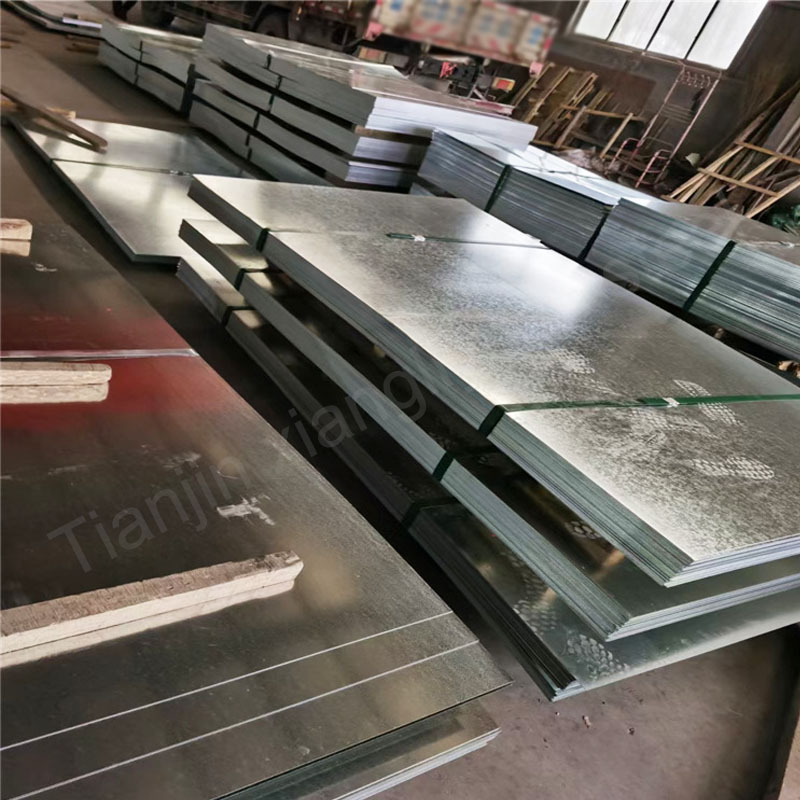

Carbon steel plates are galvanized to improve their corrosion resistance and extend their service life. The zinc coating can effectively prevent oxidation and corrosion on the surface of the steel plate, especially in applications where it is humid or exposed to outdoor environments. Galvanized carbon

Wear-resistant carbon steel plate is a carbon steel plate with high hardness and excellent wear resistance. It improves the hardness and wear resistance of steel by adding different alloy elements (such as chromium, nickel, manganese, boron, etc.) and through special heat treatment process, thereby extending

Corten carbon steel plate is a special steel plate with atmospheric corrosion resistance. It is made by adding a small amount of alloying elements (such as copper, chromium, nickel, phosphorus, silicon, etc.) to ordinary carbon steel. These alloying elements form a dense oxide layer on

There are many anti-corrosion processing technologies for steel pipes. The following are some common anti-corrosion treatment methods: Coating anti-corrosion: Epoxy resin coating: Epoxy resin has good adhesion and corrosion resistance, and is often used for internal and external corrosion protection of oil and gas pipelines.

A natural gas pipeline is a specially designed pipeline system for transporting natural gas. The materials of natural gas pipelines mainly include the following: Carbon steel: the most commonly used material, due to its high strength, good corrosion resistance and low cost. Alloy steel: used

Seamless steel pipe is a steel pipe made by perforating steel billets and is widely used in various industrial fields. Carbon steel: Commonly used ones are ASTM A53, A106, API 5L, A335, etc. ASTM A53: Seamless and welded steel pipes for general use and mechanical