Alloy steel pipe is a high-performance pipe made of carbon steel by adding alloy elements such as chromium, molybdenum, nickel, and vanadium. Its excellent strength, high temperature resistance, corrosion resistance, and creep resistance make it occupy an important position in the fields of energy, chemical

As an important metal material, galvanized square tubes are widely used in construction, machinery, transportation, municipal administration and other fields due to their excellent corrosion resistance, high strength and aesthetics. 1. Material and steel grade The base material of galvanized square tubes is mainly carbon

As a basic material in the industrial field, round steel bars have become an indispensable raw material in the fields of machinery manufacturing, construction engineering, and the automotive industry with their excellent mechanical properties and wide application scenarios. 1. Material classification and common steel grades

Black square tube, also known as carbon steel square tube, is a hollow steel tube with a square or rectangular cross-section. It is named because it has a black metal surface without surface treatment (such as galvanizing or painting). Black square tubes are widely used

I. Materials and steel grades of seamless steel pipes and welded steel pipes Seamless steel pipes and welded steel pipes use different materials and steel grades according to their uses and requirements. Common ones include: 1. Seamless steel pipes Seamless steel pipes are usually used

There are several common surface treatment methods for steel pipes. The process, characteristics and uses of each treatment method are as follows: 1. Hot-dip galvanizing - Process: Immerse the steel pipe in molten zinc liquid to make the zinc adhere to the surface to form

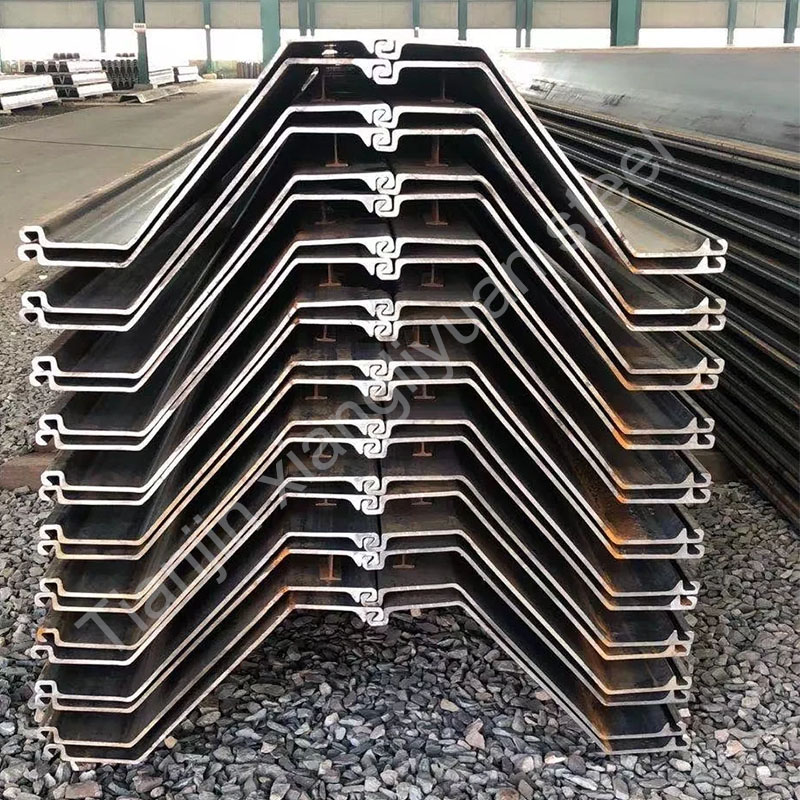

What is a Z-shaped steel sheet pile? Z-shaped steel sheet pile is a common type of steel sheet pile. Its cross-sectional shape is similar to the letter "Z" and is connected to each other by locks to form a continuous wall. Its design features make

How to change round seamless steel pipe into square steel pipe? Processing round seamless steel pipes into square seamless steel pipes is a common process requirement, which is usually used to meet specific engineering design requirements, such as building structures, machinery manufacturing or other

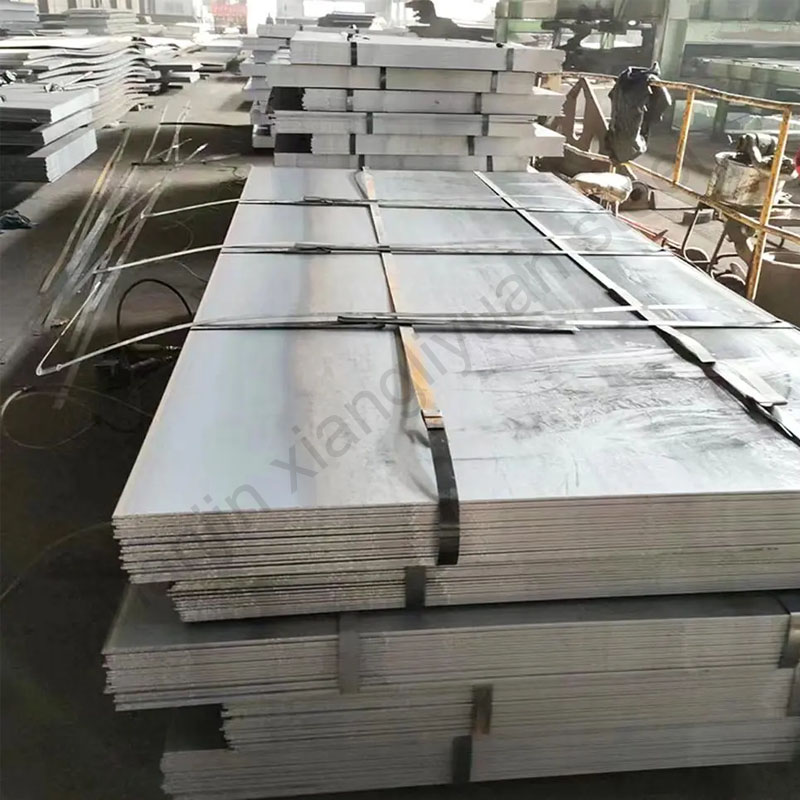

Carbon steel plate is a widely used steel in the steel industry. It is characterized by high strength, good toughness and good processing performance, and is suitable for a variety of engineering and manufacturing fields. 1. Main classification of carbon steel plates 1. Ordinary carbon

Carbon steel pipe elbows are connectors used to change the direction of pipeline fluids and are commonly found in pipeline systems in industries such as petroleum, natural gas, chemical, and electric power. Elbows are classified into three basic types: 45°, 90°, and 180°. Special angles