In the past month, China's steel industry has received a series of good news, especially in terms of rising billet prices, steady growth in steel pipe exports, and positive signs in future steel pipe price forecasts. 1. Billet price trend Since September, China's billet market

Spring steel wire is a high-strength steel specially used for making springs. It is widely used in automobile, machinery, electrical equipment and other industries. Spring steel wire has good elasticity and toughness, and also needs to have excellent fatigue resistance and wear resistance to ensure

Carbon steel elbow is a connector used in pipeline systems. It is mainly used to change the flow direction of the fluid. It can be connected to the pipeline by welding, threaded connection or flange connection. It is usually made of carbon steel material and

The main differences between hot rolled carbon steel wire and cold drawn carbon steel wire are in their processing technology, mechanical properties and appearance. Here are their main differences: Processing technology: 1. Processing temperature: Hot rolled carbon steel wire: Processed at high temperature (usually above

Profile Steel is a steel with a certain cross-sectional shape and size, which is widely used in structural engineering such as buildings, bridges, vehicles, and ships. Common types of Profile Steel include: I-beam (I-steel): The cross-section is I-shaped, mainly used in load-bearing structures, such as

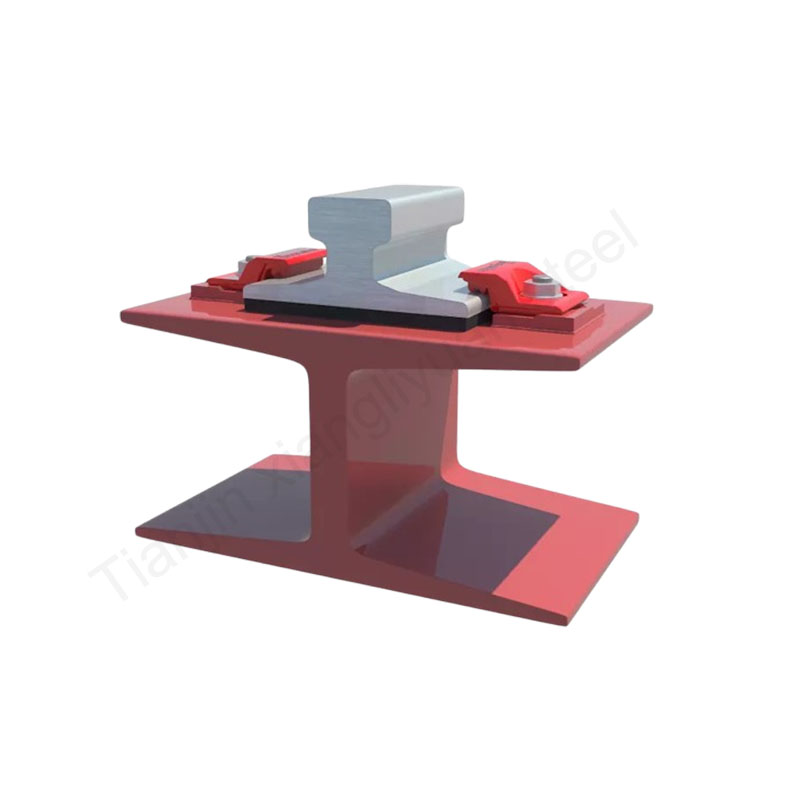

Crane rails are steel rails used to support and guide the operation of lifting equipment (such as bridge cranes, gantry cranes, etc.). Its main function is to carry the weight of the crane and ensure that the crane runs smoothly and safely on the rails.

Spiral welded pipe is a steel pipe manufactured by spiral welding technology. Spiral welded pipe is usually used to transport fluids such as oil, natural gas, water, as well as in structural engineering and bridge construction. The production method of spiral welded pipe is to

Oil casing pipe is an important equipment used to support the well wall, maintain the stability of the wellbore, protect the drilling mud backflow and prevent the well wall from collapsing during oil drilling. It is a key component of oil extraction and is widely

High-pressure boiler tubes are pipes used in boiler systems to withstand high temperatures and high pressures, and are usually required to have high strength, high temperature resistance and corrosion resistance. The materials of high-pressure boiler tubes usually include the following: Carbon steel: such as 20G

Seamless steel pipes can be divided into the following categories according to different manufacturing processes, materials and uses: 1. Classification by production process Hot-rolled seamless steel pipe: produced by high-temperature rolling, suitable for high strength and high toughness requirements, widely used in machinery, construction, oil